Description

Key Technical Specifications

- Model Number: ABB DSRF182AK02 3BSE014078R1

- Manufacturer: ABB

- Output Type: Discrete digital (Form C relays, SPDT – Single Pole Double Throw)

- Number of Output Channels: 8 (individually isolated)

- Rated Load Current: 8A @ 250V AC, 5A @ 24V DC (per channel)

- Relay Contact Rating: 10A maximum (surge, 1 second)

- Operating Temperature: -25°C to 70°C (-13°F to 158°F)

- Storage Temperature: -40°C to 85°C (-40°F to 185°F)

- Isolation: 2.5kV AC (channel-to-channel, channel-to-backplane, 1-minute withstand)

- Diagnostics: Relay contact wear detection, overcurrent/overtemperature monitoring

- Power Supply: 24V DC ±10% (21.6V DC to 26.4V DC), from AC 800M backplane

- Power Consumption: 1.5W (standby), 4.0W (all relays energized)

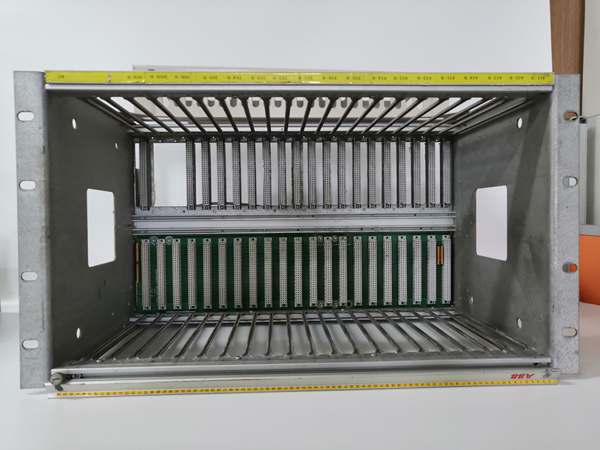

- Mounting: AC 800M I/O rack (compatible with PM850/PM860/PM861/PM865 CPUs)

- Connector Type: Spring-cage terminal block (accepts 0.5-2.5mm² wire)

- Relay Life: 100,000 operations (at rated load), 10,000,000 operations (no load)

DSRF182AK02

Field Application & Problem Solved

In industrial process control—refineries, chemical plants, and manufacturing facilities—switching high-power loads (valves, pumps, heaters) requires reliable discrete output modules that can handle current spikes and harsh conditions. The challenge? Many digital output modules use solid-state switches that fail under inductive load transients, or relay modules with insufficient isolation that cause cross-talk between channels. Others lack diagnostic feedback, leaving technicians unaware of relay wear or failed contacts until a critical load doesn’t activate—leading to process downtime. The ABB DSRF182AK02 solves these pain points with rugged Form C relays, robust isolation, and built-in fault detection.

You’ll typically find this module in applications like controlling motor starters in water treatment plants, switching solenoid valves in chemical reactors, or activating heating elements in food processing ovens. It’s a workhorse in AC 800M-based systems, where it provides 8 high-current outputs in a single rack slot—reducing wiring complexity and cabinet space. In power plants, it’s used to trigger safety interlocks (e.g., emergency shutdown valves) and control auxiliary equipment (e.g., lubrication pumps), relying on its 2.5kV isolation to withstand electromagnetic interference from generators and transformers. It also excels in applications requiring load switching flexibility, as Form C relays support both normally open (NO) and normally closed (NC) configurations.

Its core value is durability and actionable diagnostics in critical load-switching scenarios. The relays’ 8A AC/5A DC rating handles inductive and resistive loads without contact degradation, while channel isolation prevents fault propagation (a short in one channel won’t take down the entire module). Built-in contact wear and overcurrent detection flags issues early, allowing technicians to replace relays before complete failure. For operators, this means reduced unplanned downtime, faster troubleshooting, and reliable control of high-power loads—critical in 24/7 industrial environments where load failures can lead to safety hazards or production losses.

Installation & Maintenance Pitfalls (Expert Tips)

- Inductive Load Snubbers (Skipping = Relay Contact Damage): Relays driving inductive loads (motors, solenoids) produce voltage spikes when de-energized, but rookies often omit snubbers. These spikes pit and weld relay contacts, shortening their life from 100,000 cycles to a few thousand. Install RC snubbers (100Ω resistor + 0.1μF capacitor) or metal-oxide varistors (MOVs) across the load terminals. For DC loads, a freewheeling diode (rated for 1.5x load current) in reverse bias works—just ensure it’s wired directly across the load, not the module’s terminals.

- Wire Gauge vs. Load Current (Undersized = Overheating): Rookies often use thin wire (22 AWG or smaller) for high-current loads (e.g., 8A AC motors), leading to voltage drop and terminal overheating. Match wire gauge to the load: use 18 AWG for loads up to 5A, 16 AWG for 5-8A. Avoid extending wire runs beyond 100 meters—longer runs increase resistance, which compounds heating. Secure wires with ferrules to prevent strand fraying, which can cause short circuits between terminals.

- Relay Configuration Mix-Ups (NO vs. NC): Form C relays have NO and NC contacts, but rookies often wire the wrong contact for the application. For safety-critical loads (e.g., E-Stop valves), NC contacts are required to fail “safe” if power is lost—using NO contacts could leave the load energized during a fault. Double-check the wiring diagram: confirm whether the load should activate on relay energization (NO) or de-energization (NC). Test each channel manually via the AC 800M controller before commissioning to verify switching behavior.

- Ignoring Diagnostic Feedback (Missed Relay Wear): The module’s contact wear and overcurrent diagnostics are only useful if mapped to the PLC’s alarm system. Rookies often skip this step, missing early warnings of deteriorating contacts. In Control Builder M, configure diagnostic bits for each channel to trigger alarms when contact resistance exceeds 100Ω (wear indicator) or current exceeds 10A (overload). This turns reactive maintenance into proactive replacement, avoiding sudden load failures.

DSRF182AK02

Technical Deep Dive & Overview

The ABB DSRF182AK02 3BSE014078R1 is an 8-channel digital output module designed for high-power load switching in ABB’s AC 800M control systems. Its core design centers on rugged Form C (SPDT) relays, each rated for 8A AC/5A DC to handle inductive and resistive loads common in industrial settings. The module acts as an interface between the AC 800M CPU and field devices, converting digital control signals (on/off) into mechanical relay switching to activate or deactivate loads.

Each output channel is individually isolated with 2.5kV AC rating, a critical feature in noisy industrial environments. Isolation is achieved via optocouplers between the control circuit (low-voltage) and the relay driver circuit (high-voltage), preventing ground loops and electromagnetic interference from affecting the module or controller. The relays use silver-nickel contacts for improved durability and resistance to arcing, extending operational life under high-current conditions.

Communication with the AC 800M CPU occurs via the rack’s backplane bus, with control signals transmitted in real time (sub-10ms response time) to ensure fast load switching. Diagnostic data—including contact wear, overcurrent, and overtemperature—are sent back to the CPU via the same bus. Contact wear detection works by measuring contact resistance: as contacts degrade, resistance increases, and the module triggers a diagnostic flag when it exceeds a threshold (typically 100Ω).

The module draws 24V DC power from the AC 800M backplane, with separate power paths for the control circuit and relay drivers to prevent voltage drops during relay activation. A built-in thermal sensor monitors the module’s internal temperature, triggering an overload alarm if it exceeds 70°C. The spring-cage terminals simplify wiring and reduce installation time, while the module’s compact 1-slot design maximizes I/O density in the rack.

Built for industrial ruggedness, the DSRF182AK02 withstands vibration (up to 5g at 10-2000Hz) and temperature extremes (-25°C to 70°C), making it suitable for harsh environments like refineries and chemical plants. Its hot-swappable capability (with compatible AC 800M racks) allows module replacement without shutting down the control system, minimizing downtime. The module’s compliance with industrial standards (IEC 61131-2, CE, UL) ensures compatibility with global industrial applications, while its long relay life reduces maintenance frequency and lifecycle costs.