Description

| Parameter Name | Parameter Value |

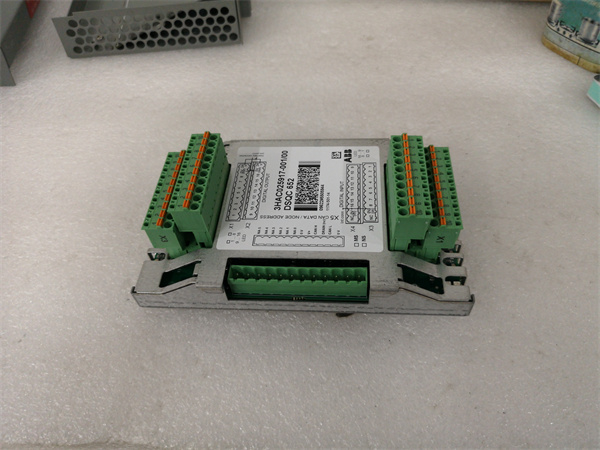

| Product Model | ABB DSQC652 |

| Manufacturer | ABB |

| Product Category | Digital I/O Module |

| Input Voltage | 24V DC (±10%) |

| Number of Digital Inputs | 16 (sink/source configurable) |

| Number of Digital Outputs | 16 (0.5A per channel) |

| Communication Interface | DeviceNet |

| Operating Temperature | 0°C to 55°C (32°F to 131°F) |

| Protection Rating | IP20 |

| Mounting Type | DIN Rail |

| Dimensions (W x H x D) | 70mm x 100mm x 59mm |

| Weight | 200g |

ABB DSQC652

Product Introduction

The ABB DSQC652 is a high-performance digital I/O module designed for industrial automation applications. As part of ABB’s renowned robotics and control portfolio, this module provides reliable signal interfacing between PLCs, robotic controllers, and field devices. The DSQC652 supports 16 configurable digital inputs and 16 transistor outputs, making it ideal for flexible automation setups.

Engineered for seamless integration with ABB’s robotic systems, the DSQC652 operates on DeviceNet, ensuring fast and deterministic communication. Its compact DIN rail mounting design simplifies installation in control cabinets, while the wide operating temperature range ensures stability in harsh industrial environments. Whether used in automotive manufacturing or material handling, the ABB DSQC652 delivers precision and durability.

Core Advantages and Technical Highlights

High-density I/O configuration: The ABB DSQC652 offers 32 channels in a compact form factor, reducing panel space and wiring complexity. Its sink/source input flexibility accommodates diverse sensor and switch types without additional hardware.

Robust communication: With DeviceNet compatibility, the module ensures real-time data exchange and easy integration into ABB’s automation ecosystems. The built-in diagnostics simplify troubleshooting, minimizing downtime.

Durability in harsh conditions: Rated for operation up to 55°C and featuring surge protection on all channels, the DSQC652 excels in demanding environments like welding shops and foundries.

Plug-and-play installation: The tool-free terminal blocks and DIN rail mounting enable rapid deployment, while the LED status indicators provide instant visual feedback for each channel.

Typical Application Scenarios

The ABB DSQC652 is widely used in robotic workcells for automotive assembly lines, where it interfaces with grippers, sensors, and safety interlocks. Its high-speed response (≤1ms per channel) ensures synchronization with robotic motions.

In packaging machinery, the module controls actuators and photoelectric sensors, leveraging its configurable outputs to drive solenoids and relays. The DeviceNet backbone allows centralized monitoring, critical for predictive maintenance.

For material handling systems, the DSQC652’s rugged design handles vibration and dust, making it suitable for conveyor control in warehouses and distribution centers.

ABB DSQC652

Related Model Recommendations

ABB DSQC651: 8-input/8-output variant for smaller-scale applications.

ABB DSQC653: 32-input version, ideal for sensor-heavy setups.

ABB DSQC654: Relay output module for high-current loads (up to 5A).

ABB DSQC655: PROFIBUS-DP version for Siemens PLC integration.

ABB DSQC656: Redundant I/O module for fail-safe systems.

Installation, Commissioning, and Maintenance Instructions

Installation preparation: Ensure the control cabinet environment meets IP20 standards and has adequate ventilation. Use a 24V DC power supply with proper grounding. DeviceNet termination resistors (121Ω) must be installed at network ends.

Maintenance suggestions: Regularly inspect terminal block tightness to prevent loose connections. Clean the module with a dry cloth to avoid dust accumulation. Replace any channel showing consistent LED faults, as this may indicate internal component wear.

Service and Guarantee Commitment

ABB provides a 36-month warranty for the DSQC652, covering defects in materials and workmanship. Global technical support is available 24/7 via ABB’s service network. Customers receive lifetime access to firmware updates and configuration tools. On-site repair services can be arranged for critical failures, ensuring minimal disruption to operations.