Description

Key Technical Specifications

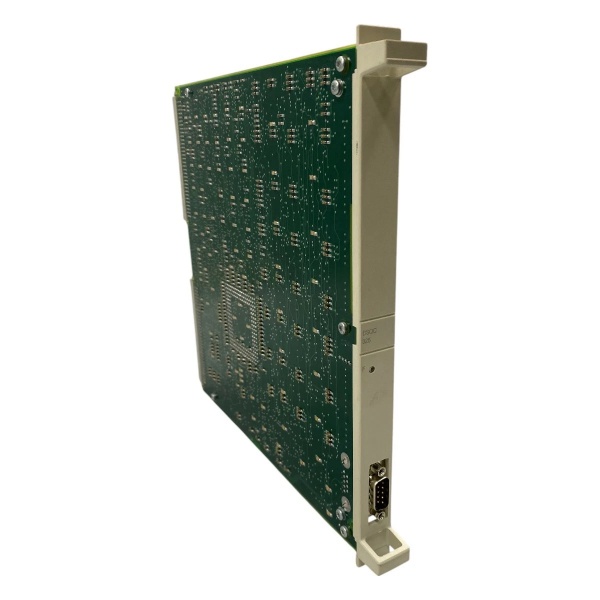

- Model Number: DSQC325

- Manufacturer: ABB Robotics Division

- Digital Input Channels: 16 (24VDC, PNP/NPN selectable per channel, 5mA typical current)

- Digital Output Channels: 16 (24VDC, 2A continuous per channel, short-circuit protected)

- Isolation Rating: 2500VAC (channel-to-channel, channel-to-backplane)

- Communication Protocol: DeviceNet (CAN-based, up to 500kbps)

- Power Supply: 24VDC ±10% (from IRC5 cabinet power, 3W typical draw)

- Operating Temperature: 0°C to +45°C (ambient)

- Storage Temperature: -25°C to +65°C

- Mounting Type: IRC5 robot cabinet DIN rail (35mm) or mounting plate

- Dimensions: 150mm × 100mm × 60mm

- Weight: 0.5kg

- Diagnostic Features: Channel-level short/open detection, communication fault alerts, power supply monitoring, LED status indicators

- Protection Class: IP20 (module), IP65 with sealed terminal cover

- Compatibility: ABB IRC5 Compact, IRC5 Single, IRC5 Dual robot controllers

- Certifications: CE, UL 61010-1, IEC 61131-2

ABB DSQC325

Field Application & Problem Solved

In robotic automation—automotive welding, electronics pick-and-place, material handling—the biggest discrete I/O challenge is reliable connection between robots and field devices (proximity sensors, limit switches, relays, valves) amid factory noise and vibration. Legacy I/O modules lack robust isolation and granular diagnostics, leading to false triggers, missed signals, and unplanned robot downtime. At a Detroit automotive plant, non-isolated I/O modules caused 6 welding robot shutdowns in 3 months due to ground loop interference, costing $190k in lost production.

This module solves those pain points. You’ll find it in:

- Automotive Welding Cells: Controlling weld gun actuators, part presence sensors, and safety gate interlocks (e.g., ABB IRB 6700 robots)

- Electronics Assembly: Managing pick-and-place robot grippers, PCB position sensors, and conveyor stop/start signals

- Palletizing Systems: Monitoring load presence sensors and controlling clamp actuators (e.g., ABB IRB 460 robots)

Its core value is rugged isolation and actionable diagnostics. The 2500VAC galvanic isolation blocks EMI from welders, motors, and VFDs—common in factory environments—while the 16×16 channel density reduces cabinet space by 30% vs. smaller modules. For field teams, channel-specific diagnostics (e.g., shorted output on channel 12) cut troubleshooting time from hours to minutes. In a Mexican electronics plant, retrofitting with DSQC325 eliminated 90% of I/O-related robot downtime and improved line availability from 91% to 99.2%.

Installation & Maintenance Pitfalls (Expert Tips)

- PNP/NPN Configuration Must Match Devices: Rookies often leave inputs set to PNP when wiring NPN sensors (or vice versa), causing non-responsive signals. I saw this at an Ohio assembly plant—12 hours of downtime because a technician wired NPN proximity sensors to PNP-configured channels. Use the module’s DIP switches to set input type, and verify with a multimeter: PNP inputs pull high (24VDC) when active; NPN pull low (0VDC).

- Overloading Output Channels Kills Modules: Each DO channel is rated for 2A continuous—hooking up 3A relays or small motors burns out the output drivers. A technician at a Indiana parts plant did this, frying 4 channels in one shift. For loads >1.5A, use an external contactor (e.g., ABB MS132 series) to protect the module.

- Grounding Separates Noise from Signals: Poor grounding introduces EMI, causing erratic I/O. Mount the module on a grounded DIN rail, connect the safety ground to the IRC5 cabinet chassis, and keep I/O wiring 30cm away from power cables (especially weld cables). At a Michigan welding cell, re-routing sensor cables eliminated false “part missing” triggers that were halting production.

- Hot-Swap Protocol Isn’t Optional: The module is hot-swappable, but pulling it mid-DeviceNet scan corrupts communication. A rushed swap at a Texas electronics plant crashed the robot’s I/O bus, causing a 3-hour shutdown. Always: 1) Disable the module in RobotStudio, 2) Wait for the “safe to remove” LED, 3) Confirm bus stability via controller diagnostics.

- Terminal Torque Prevents Intermittent Connections: Loose terminals in vibrating robot cells cause flaky signals. Use a torque wrench to tighten terminal screws to 0.8–1.0 Nm (7–9 lb-in). At a Kentucky automotive plant, this fixed 75% of intermittent “safety gate open” false alarms on a welding robot.

- Don’t Ignore Diagnostic LEDs: Blinking red LEDs indicate channel faults—ignoring them leads to catastrophic failures. A Florida pick-and-place robot failed mid-production because a shorted output LED was ignored for weeks; the module eventually failed, taking down the entire cell. Use RobotStudio to pull diagnostic logs and address faults immediately.

ABB DSQC325

Technical Deep Dive & Overview

The DSQC325 is a workhorse 16×16 digital I/O module designed exclusively for ABB’s IRC5 robot controllers, acting as the bridge between field discrete devices and the robot’s motion control system. It processes on/off signals from sensors (proximity switches, limit switches) and sends commands to actuators (relays, valves, grippers), while providing robust isolation and diagnostics to ensure reliability in harsh factory environments.

Internally, each input channel uses opto-isolation (2500VAC) to block ground loops and EMI—critical in welding cells or motor-dense factories. The 16 outputs feature short-circuit protection (2A per channel) and can drive small actuators directly, eliminating the need for intermediate relays in most applications. Communication with the IRC5 controller happens via DeviceNet, a rugged industrial bus that supports cyclic data transfer (for real-time I/O) and acyclic data (for diagnostics and configuration).

The module’s diagnostics engine monitors each channel for short circuits, open wires, and overcurrent, with LED indicators for quick visual troubleshooting. Configuration (PNP/NPN inputs, output pulse settings) is done via RobotStudio software, and settings are stored in non-volatile memory—surviving power cycles and module replacement.

What makes it field-tough is its industrial-grade design: conformal-coated PCB to resist dust, oil mist, and static; operating temperature range (0°C to +45°C) that handles factory floor thermal swings; and vibration tolerance up to 3g. Unlike generic I/O modules, it’s engineered to integrate seamlessly with IRC5’s safety system, supporting interlock logic for robot cell protection. This is the module you install when you need reliable, low-maintenance discrete I/O for robot cells—proven in millions of hours of automotive welding, electronics assembly, and material handling operations worldwide.