Description

Key Technical Specifications

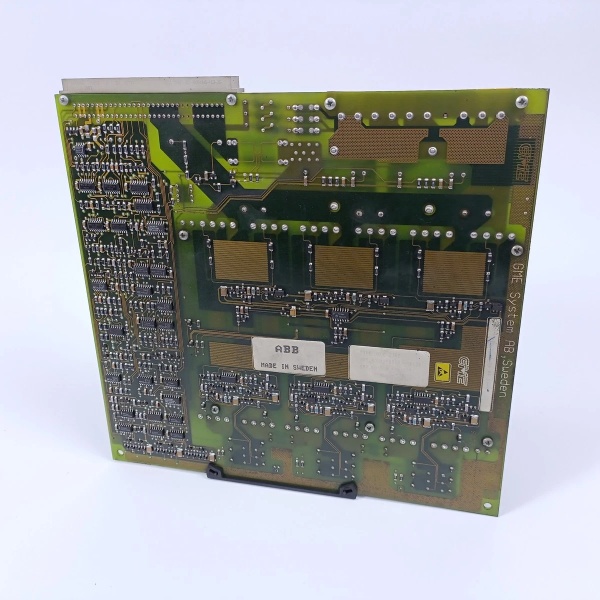

- Model Number: DSQC236T

- Manufacturer: ABB Robotics Division

- I/O Configuration: 16 isolated digital inputs (DI), 16 isolated digital outputs (DO)

- Operating Voltage: 24VDC ±10% (DI/DO circuits)

- Input Current: 4mA per DI (sinking/sourcing configurable)

- Output Rating: 2A per DO (resistive load), 0.5A per DO (inductive load)

- Isolation Rating: 500V AC (channel-to-channel), 1kV AC (I/O circuits to backplane)

- Communication Interface: IRC5 controller internal backplane (real-time data exchange)

- Operating Temperature: 0°C to +45°C (32°F to +113°F)

- Mounting Type: Plug-in module, IRC5 controller rack-mount (1U height)

- Certifications: CE, UL 1998, RoHS 2.0, IEC 61131-2

- Compatibility: ABB IRC5 Compact/Panel/MultiMove controllers; IRB 120/4600/6700/7600 robot series

- Diagnostic Capability: Built-in short-circuit protection for outputs, channel status feedback to IRC5 CPU

ABB DSQC236T

Field Application & Problem Solved

In industrial robotics—automotive welding, electronics assembly, heavy-duty material handling—robots rely on precise digital I/O to interact with end-effectors, safety systems, and production line equipment. Generic digital I/O modules fail to integrate with ABB IRC5 controllers, causing communication delays, false signals, and unplanned downtime. A Michigan auto plant lost $190k in a 4-hour outage when a generic I/O module failed to trigger a weld gun’s safety interlock, halting the entire body shop line. Legacy I/O solutions also suffer from poor durability: a Texas electronics facility spent $22k annually replacing off-brand modules that couldn’t withstand the vibration of material handling robots.

You’ll find this I/O module installed in IRC5 controllers powering ABB robots: IRB 6700 welding robots (controlling weld gun actuation and seam sensors), IRB 4600 material handlers (managing gripper open/close and part presence sensors), and IRB 120 assembly robots (triggering feeder systems and safety doors). Its core value is ABB-native integration + rugged industrial design + reliable I/O signal handling. The direct IRC5 backplane connection eliminates latency, while isolated channels block electrical noise from robot motors and VFDs. For a Pennsylvania aerospace plant, the module’s short-circuit protection prevented weld gun damage during a wiring fault—something generic modules failed to do, costing $15k in repairs annually.

Installation & Maintenance Pitfalls (Expert Tips)

- Voltage Mismatch: Never Use AC on 24VDC Circuits: Rookies mistakenly wire 110VAC to the 24VDC I/O channels, frying the module. An Ohio metal fabricator destroyed three modules ($1,800 total) before verifying the power source. Use a multimeter to confirm 24VDC before wiring—label channels clearly to avoid mix-ups.

- Terminal Torque: Tighten to 0.8Nm: Loose terminals cause intermittent I/O signals, leading to robot missteps. A Florida plastics plant’s packaging robots failed to detect parts until technicians torqued terminals to ABB’s specified 0.8Nm. Use a precision torque screwdriver—over-tightening strips threads; under-tightening causes arcing.

- Firmware Sync with IRC5 Controller: Outdated module firmware (pre-v6.2) with IRC5 v7.0+ causes I/O channel detection failures. A Illinois food processing plant’s robot grippers failed to actuate until the DSQC236T was updated via RobotStudio. Always match I/O module firmware to the controller’s version—mismatched versions corrupt signal data.

- Test All I/O Channels After Installation: Skip the “power-on and assume” approach. Use RobotStudio’s I/O test tool to simulate inputs and verify outputs, ensuring each channel functions as expected. A North Carolina furniture plant missed a faulty output channel during installation, leading to a 3-hour outage when the robot couldn’t release parts.

ABB DSQC236T

Technical Deep Dive & Overview

The ABB DSQC236T is a dedicated digital I/O module engineered to extend the connectivity of ABB IRC5 robot controllers, serving as the interface between the robot’s CPU and field devices. It plugs directly into the IRC5’s internal backplane, communicating with the main CPU via a high-speed data bus—this eliminates the latency and compatibility issues of generic I/O modules that require external wiring or gateways.

Each of the 16 digital inputs is configurable for sinking or sourcing, accommodating a wide range of sensors (photoelectric, limit switches, proximity sensors). The 16 digital outputs feature short-circuit protection, automatically shutting down a channel if a wiring fault is detected to prevent module damage. The module’s isolation design (500V AC channel-to-channel) blocks electrical noise from robot motors and industrial equipment, ensuring reliable signal transmission— a critical feature in noisy manufacturing environments.

Unlike generic I/O modules, the DSQC236T integrates seamlessly with ABB’s RobotStudio software, allowing technicians to map I/O channels to robot logic, monitor status in real time, and troubleshoot faults remotely. Its compact 1U design fits tightly in IRC5 controller racks, making it ideal for space-constrained production lines. For facilities where robot I/O reliability directly impacts productivity and safety, this module isn’t just a connectivity component—it’s a rugged, precision-engineered solution that keeps ABB robots interacting seamlessly with their environment.