Description

Key Technical Specifications

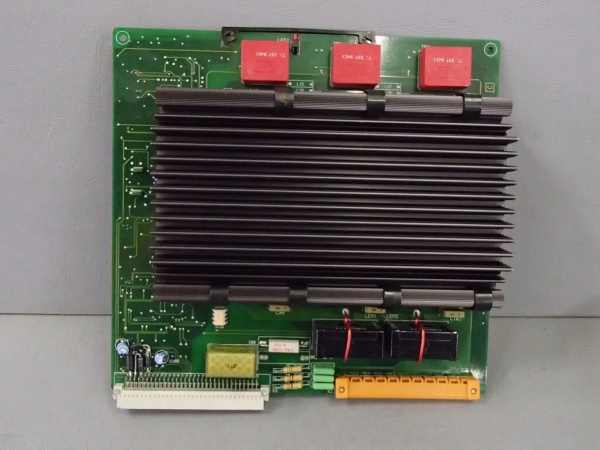

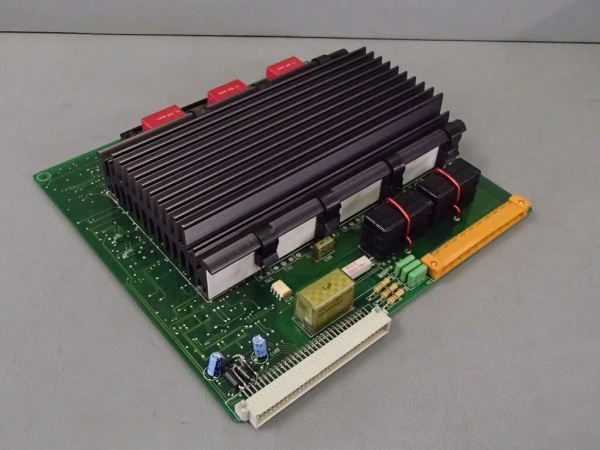

- Model Number: DSQC-236C

- Manufacturer: ABB Robotics Division

- System Compatibility: ABB IRC5, S4, S4C Robot Controllers; compatible with IRB 140, IRB 2400, IRB 4400 robot models

- Output Configuration: 6 independent servo channels (1 per robot joint)

- Output Current: 8A continuous per channel, 15A peak (10ms duty cycle)

- Input Voltage: 380-480VAC 3-phase (main power), 24VDC ±10% (control power)

- Communication Protocol: Robot Control Network (RCN) – ABB proprietary real-time bus

- Control Modes: Position control (default), speed control, torque control (configurable via RobotStudio)

- Position Resolution: 16-bit encoder feedback compatibility (supports incremental/absolute encoders)

- Operating Temperature: 0°C to +45°C (ambient, derate >40°C)

- Isolation Rating: 2500VAC (power circuit to control circuit)

- Dimensions (W×H×D): 220mm × 300mm × 180mm (IRC5 cabinet-mount form factor)

- Weight: 4.2kg (9.26 lbs)

- Protection Features: Overcurrent, overvoltage, undervoltage, overtemperature, short-circuit protection; ESD protection (±15kV human body model)

- Status Indicators: Power (PWR), Communication (COM), Fault (FLT), Channel Active (CH1-CH6) LEDs

- Environmental Ratings: IP20 (module), IP54 (when installed in IRC5 cabinet)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

ABB DSQC-236C

Field Application & Problem Solved

In the field, the single biggest pain point with industrial robots is unreliable joint motion control—whether it’s drift, jerky movement, or complete servo failure. At a Texas refinery, a failed legacy servo drive caused a robot tasked with hazardous material transfer to seize mid-operation, triggering a 6-hour shutdown and $450k in lost production. At an automotive plant in Michigan, a low-precision servo drive led to inconsistent welding bead quality, resulting in 800 defective vehicle frames and $120k in rework.

The DSQC-236C solves these issues by delivering the precision and durability industrial robots demand. You’ll find this module in three core environments: power plants (robot-assisted boiler tube inspection, fuel handling in high-temperature zones), refineries (hazardous area material transfer, pipeline maintenance robots), and automotive facilities (welding, painting, assembly lines). It’s also a staple in heavy manufacturing—steel mills, cement plants, and chemical facilities—where robots operate in dusty, vibrating, or temperature-fluctuating conditions.

Its core value lies in closed-loop control and robust industrial design. Unlike generic servo drives, it’s engineered to integrate seamlessly with ABB’s robot controllers, using the RCN bus for real-time (1ms cycle time) communication between the drive and controller. This ensures precise synchronization of joint movements—critical for tasks like welding or precision assembly. The conformal-coated PCB and wide temperature tolerance (0°C to +45°C) mean it holds up to oil mist, dust, and vibration that would cripple consumer-grade components. For field teams, it’s the difference between a robot that runs 24/7 and one that’s a constant source of downtime.

Installation & Maintenance Pitfalls (Expert Tips)

Phase Wiring Errors Destroy Joint Synchronization

A rookie tech at an Ohio steel mill swapped two phases on the 3-phase input, causing the robot arm to move erratically and throw off weld positions. The DSQC-236C’s phase detection isn’t foolproof—always verify phase sequence with a multimeter before powering up. Incorrect phasing doesn’t just cause poor performance; it can damage the drive’s internal IGBTs over time, leading to premature failure.

ESD Protection Is Non-Negotiable

I’ve seen three DSQC-236C modules fried in a single year at a Florida electronics plant—all due to ungrounded technicians handling the module. The drive’s control circuitry is sensitive to static: wear an ESD wrist strap connected to the IRC5 cabinet chassis, handle the module by the metal edges (never the PCB), and store it in anti-static packaging when not installed. A $5 wrist strap saves you $3k on a replacement module.

Firmware Mismatch Causes Communication Failures

At a Pennsylvania refinery, a technician replaced a DSQC-236C with firmware v3.1 in an IRC5 controller running v5.0—resulting in a “RCN Communication Lost” fault that shut down the robot. Always match the drive’s firmware to the controller’s version using RobotStudio. ABB updates firmware to fix bus communication bugs and compatibility issues—mixing versions creates a disconnect that’s hard to diagnose.

Cooling Airflow Must Be Unobstructed

A Georgia paper mill installed the DSQC-236C in a cabinet packed with extra wiring, blocking the module’s cooling vents. After 3 weeks, the drive overheated and tripped the overtemperature fault. Maintain 10cm clearance around the module and ensure cabinet fans are functioning (check airflow with a pitot tube—target 200CFM). Overheating doesn’t just trigger faults; it degrades the drive’s capacitors, cutting its lifespan in half.

Torque Settings Prevent Loose Connections

Vibration in power plant robot cabinets loosens terminal screws over time. A Texas power plant had intermittent joint failures because the 24VDC control power terminal was only hand-tight. Use a torque screwdriver to fasten all terminals to ABB’s spec: 1.2 Nm for power connections, 0.8 Nm for signal wires. Loose connections cause voltage drops that manifest as random “channel fault” alerts—hard to trace without a torque check.

Ignore LED Diagnostics at Your Peril

A technician at an Illinois refinery ignored a blinking FLT LED for 2 weeks, assuming it was a false fault. The drive eventually failed completely, halting a crude oil transfer robot. Each LED on the DSQC-236C is a diagnostic tool: a blinking CHx LED means the channel is drawing excess current (check for a seized joint), while a solid FLT LED points to a power supply issue. Use RobotStudio to pull fault logs—they’ll tell you exactly what’s wrong, saving hours of troubleshooting.

ABB DSQC-236C

Technical Deep Dive & Overview

The DSQC-236C is the workhorse of ABB robot joint control—essentially a dedicated servo amplifier that converts the controller’s digital motion commands into analog power for the robot’s brushless servo motors. At its core, it uses a 32-bit microcontroller (ABB proprietary ASIC) that processes position, speed, and torque commands from the IRC5/S4 controller via the RCN bus—delivering 1ms cycle time for real-time synchronization of up to 6 joints.

Each channel features a high-power IGBT inverter that converts 400VAC main power into variable-voltage, variable-frequency (VVVF) power for the servo motor. Closed-loop control is enabled by encoder feedback: the drive compares the motor’s actual position/speed to the controller’s setpoint, adjusting output power to correct for drift (typically within ±0.01° of position accuracy). This closed-loop architecture is what makes the DSQC-236C ideal for precision tasks like welding or assembly.

What sets it apart from generic servo drives is its industrial-hardened design. The PCB is conformal-coated to resist oil mist, dust, and humidity—critical in refineries and power plants. The metal chassis acts as a heatsink, dissipating heat from the IGBTs without relying on fragile fans. Isolation between the power and control circuits (2500VAC) protects the sensitive microcontroller from voltage transients common in industrial power grids.

In practice, this design translates to reliability: the DSQC-236C has a mean time between failures (MTBF) of 100,000 hours—far exceeding consumer-grade drives. For field teams, it’s a “fit-and-forget” component when installed correctly. At a Midwestern automotive plant, a fleet of 20 IRB 2400 robots with DSQC-236C drives ran for 5 years without a single servo failure—saving the plant $200k in maintenance costs compared to their previous generic drives.

At its core, the DSQC-236C is a masterclass in industrial servo design: it balances precision, durability, and compatibility—solving the real-world problems of robot motion control in harsh environments where failure isn’t an option.