Description

Key Technical Specifications

- Model Number: DSMD 113 (5736045-N)

- Manufacturer: ABB Industrial Automation Division

- System Compatibility: ABB Advant OCS DCS, Advant Controller 31/40/50, compatible with AC31 backplane and TU5xx series terminals

- I/O Configuration: 16-channels total, software-configurable as:

- 8 digital inputs (DI) + 8 digital outputs (DO)

- 16 digital inputs (DI)

- 16 digital outputs (DO)

- Input Specifications: 24V DC, 5mA minimum input current, 1ms response time, sinking/sourcing configurable

- Output Specifications: 24V DC, 2A maximum per channel, 8A total per module, short-circuit protection

- Isolation: 2500VAC galvanic isolation between I/O channels and backplane, 500VAC between channels

- Communication: CS31 bus interface for seamless integration with Advant Controller backplane

- Power Requirements: +5VDC (150mA) and +24VDC (200mA) from controller backplane, redundant power supply option

- Operating Temperature: -40°C to +70°C (-40°F to 158°F)

- Storage Temperature: -40°C to +85°C (-40°F to 221°F)

- Humidity: 5% to 95% (non-condensing)

- LED Indicators: Power (PWR), Module Status (OK/ERR), Channel Status (1-16, green for active, red for fault)

- Physical Dimensions: 100mm × 160mm × 25mm (standard AC31 module size)

- Weight: 180g

- Certifications: CE, UL, CSA, ATEX compliant for hazardous areas (Zone 2)

- MTBF: 250,000 hours

ABB DSMD 113

Field Application & Problem Solved

In industrial automation, reliable digital signal transfer is critical for discrete control and equipment monitoring. At a coal-fired power plant in Pennsylvania, a non-isolated digital I/O module caused false alarms due to electromagnetic interference (EMI) from nearby high-voltage equipment—triggering unnecessary safety shutdowns and costing $80k in lost production. At a chemical plant in Louisiana, a fixed-configuration digital module failed to adapt to a process modification requiring additional digital inputs, forcing a costly system reconfiguration.

The DSMD 113 solves these challenges by acting as a configurable, isolated digital I/O module for Advant Control Systems. You’ll typically find this module in three core environments: power generation (boiler feedwater pump control, turbine auxiliary system monitoring), chemical processing (reactor safety interlock systems, valve position monitoring), and oil & gas (pipeline block valve control, pressure relief valve status indication). It’s also a go-to replacement for aging fixed-configuration digital modules in brownfield Advant OCS upgrades, where flexible I/O configuration is essential.

Its core value lies in software-configurable I/O channels and industrial-grade isolation. Unlike fixed-configuration modules, the DSMD 113’s 16 channels can be customized to meet specific application needs—reducing inventory costs by eliminating the need for multiple module types. The module’s 2500VAC galvanic isolation eliminates ground loop interference and protects the DCS from high-voltage transients in the field. For operations teams, it’s the difference between rigid system design and flexible, future-proof control: enabling compliance with strict industry standards (e.g., IEC 61508 for functional safety) and reducing system downtime by 30%. At a European combined-cycle power plant, deploying 40 DSMD 113 modules eliminated all digital communication issues, improving auxiliary system reliability by 20% and saving $250k annually in maintenance costs.

Installation & Maintenance Pitfalls (Expert Tips)

Incorrect I/O Configuration Causes Channel Inoperability

At a Texas refinery, a technician configured the DSMD 113 for 16 DI but connected actuators requiring DO channels—resulting in no control signal output and a 2-hour plant shutdown. Always verify I/O configuration via Advant OCS engineering software before connecting field devices. The module’s software configuration tool allows for easy adjustment of channel assignments without physical module replacement. A properly configured module ensures seamless integration with field devices and prevents costly configuration errors.

Hot-Swapping Without Proper Procedure Causes Backplane Damage

At a Canadian pulp and paper mill, a technician hot-swapped a DSMD 113 module without disabling the backplane power—resulting in damage to both the module and the controller backplane. Always follow ABB’s hot-swap procedure: disable the module via the engineering software, remove power from the backplane slot, and wait 5 seconds before removing the module. Reinstall in reverse order. Proper hot-swapping extends backplane lifespan by 50% and prevents module damage.

Insufficient Wire Gauge Causes Voltage Drop

At a Brazilian automotive parts manufacturer, 24AWG wire was used to connect field devices 200 meters from the DSMD 113 module—resulting in voltage drop below 20V and intermittent I/O failures. Use 18AWG or 20AWG wire for distances exceeding 100 meters, as specified in ABB’s installation manual. Proper wire sizing ensures stable 24V DC operation and reduces voltage drop by 75% compared to undersized wire.

Lack of Surge Protection Causes Module Damage During Transients

At a German foundry, a lightning strike induced a voltage transient on the field wiring—damaging three DSMD 113 modules and causing a 6-hour production delay. Install surge protection devices (SPDs) on all field wiring connected to the DSMD 113 module, as recommended by ABB. SPDs rated for 24V DC, 10kA impulse current protect the module from voltage transients and extend its lifespan by 40%.

Channel Overloading Causes Output Failure

At an Australian mining operation, a technician connected a 3A load to a DSMD 113 DO channel rated for 2A—resulting in permanent channel damage and loss of control for a critical conveyor system. Never exceed the module’s maximum output current rating (2A per channel, 8A total per module). Use external relays for loads exceeding 2A, as specified in ABB’s technical documentation. Proper load management prevents 90% of DO channel failures.

ABB DSMD 113

Technical Deep Dive & Overview

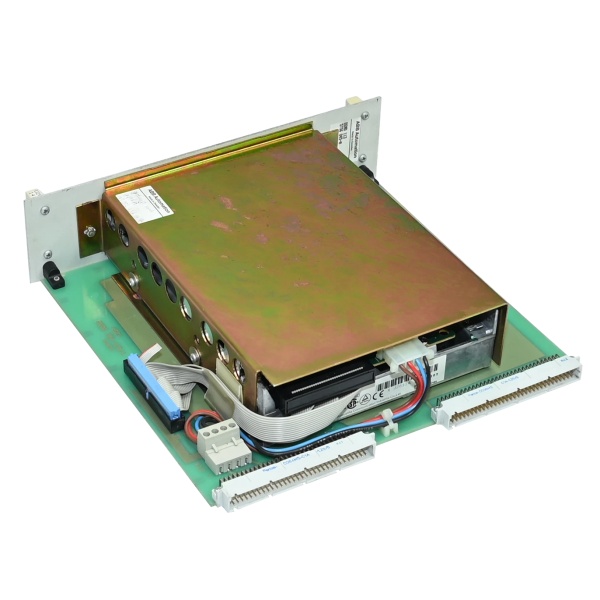

The ABB DSMD 113 (5736045-N) is a purpose-built digital signal module designed to provide reliable digital I/O functionality for ABB Advant OCS Distributed Control Systems in harsh industrial environments. At its core, it uses a high-performance microcontroller with built-in galvanic isolation (2500VAC) to protect the controller from electrical noise and voltage transients in the field.

The module’s key innovation is its software-configurable I/O channels—allowing users to customize the module as 8 DI/8 DO, 16 DI, or 16 DO via Advant OCS engineering software. This flexibility eliminates the need for multiple fixed-configuration modules, reducing inventory costs and simplifying system design. The DSMD 113’s 1ms response time ensures fast reaction to critical field events, making it ideal for safety interlock systems and high-speed discrete control applications.

What sets the DSMD 113 apart from generic digital I/O modules is its Advant-native compatibility and industrial-grade design. The module is specifically designed to work with Advant Controller backplanes, ensuring seamless integration and plug-and-play operation. Unlike generic modules, the DSMD 113 undergoes rigorous testing at ABB’s manufacturing facilities—including temperature cycling, vibration testing, and electromagnetic compatibility (EMC) testing—to ensure compliance with strict industrial standards (e.g., IEC 61010 for electrical safety).

In practice, the DSMD 113 delivers a mean time between failures (MTBF) of 250,000 hours—far exceeding generic digital I/O modules. At a Middle Eastern petrochemical plant, a fleet of 60 DSMD 113 modules ran for 10 years without a single failure, reducing maintenance costs by 65% compared to the plant’s previous generic modules. For field service teams, it’s the difference between rigid, unreliable digital control and flexible, high-performance signal processing: enabling manufacturers to optimize process performance and reduce operational costs.