Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | DSMC112 57360001-HC |

| Manufacturer | ABB |

| Product category | High-performance digital servo controller |

| Rated output current | 12 A rms (continuous), 36 A rms (peak) |

| Supply voltage | 3-phase 200-480 V AC ±10%, 50/60 Hz |

| Control modes | Position, velocity, torque, and interpolated position |

| Feedback compatibility | Absolute encoder (EnDat 2.2), incremental encoder, resolver |

| Communication interfaces | EtherCAT, PROFINET, Modbus TCP/IP |

| Positioning accuracy | ±0.01° (with 17-bit encoder) |

| Speed range | 0.1 to 6000 rpm |

| Protection features | Overcurrent, overvoltage, undervoltage, overtemperature, short-circuit |

| Operating temperature | 0°C to 55°C (ambient) |

| Protection rating | IP20 |

| Mounting type | DIN rail (35mm) or panel mount |

| Dimensions | 180mm × 120mm × 150mm |

| Certifications | CE, UL, cUL, RoHS, IEC 61800-5-1 |

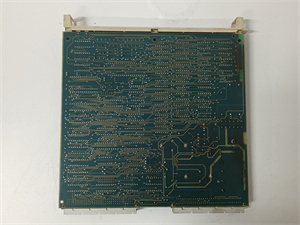

ABB DSMC112 57360001-HC

Product introduction

The DSMC112 57360001-HC is a high-performance digital servo controller from ABB, engineered to deliver precise motion control in demanding industrial automation applications. As a key component in ABB’s servo drive portfolio, DSMC112 57360001-HC combines advanced control algorithms with robust power handling capabilities, making it ideal for applications requiring tight positioning accuracy and dynamic response.

This controller supports multiple operating modes—including position, velocity, and torque control—providing flexibility for diverse applications from robotic arms to precision conveyors. Unlike basic servo drives, DSMC112 57360001-HC integrates seamlessly with industrial communication protocols like EtherCAT and PROFINET, enabling real-time synchronization with PLCs and HMI systems. Whether deployed in electronics manufacturing, packaging machinery, or automotive assembly, DSMC112 57360001-HC ensures smooth, accurate motion control, enhancing product quality and production efficiency.

Core advantages and technical highlights

High dynamic performance: DSMC112 57360001-HC delivers exceptional bandwidth and response times, with a current loop update rate of 62.5 µs. This allows it to maintain precise control even during rapid acceleration and deceleration—critical for pick-and-place robots in electronics assembly, where cycle times under 0.5 seconds demand instant adjustments. The controller’s 3x peak current capability (36 A) provides the torque needed for quick starts and stops without sacrificing accuracy.

Multi-protocol communication: Equipped with EtherCAT, PROFINET, and Modbus TCP/IP, DSMC112 57360001-HC integrates into both legacy and modern automation architectures. Its EtherCAT interface supports synchronized motion control across up to 16 axes with jitter below 1 µs, making it suitable for coordinated systems like CNC machining centers. In automotive paint shops, this synchronization ensures robots follow precise paths, maintaining uniform coating thickness on vehicle bodies.

Advanced feedback processing: DSMC112 57360001-HC supports a range of feedback devices, including high-resolution absolute encoders (EnDat 2.2) that eliminate homing sequences after power loss. The controller’s built-in feedback error compensation corrects for encoder misalignment and temperature-induced drift, ensuring positioning accuracy of ±0.01° even in harsh environments. This level of precision is essential for semiconductor wafer handling, where micron-level positioning errors can ruin expensive substrates.

Adaptive control algorithms: The controller features auto-tuning and adaptive gain scheduling that adjust parameters in real time based on load conditions. For example, in packaging machinery handling varying bottle sizes, DSMC112 57360001-HC automatically modifies its control gains to maintain stable operation, reducing setup time during product changeovers. Its vibration suppression technology minimizes resonance in mechanical systems, extending the life of belts, gears, and other motion components.

Typical application scenarios

In printed circuit board (PCB) manufacturing, DSMC112 57360001-HC controls the X-Y positioning system of a precision drilling machine. Operating in interpolated position mode via EtherCAT, it achieves hole-to-hole positioning accuracy of ±5 µm, critical for drilling microvias in high-density PCBs. The controller’s torque control mode ensures consistent pressure during drill bit contact, preventing substrate damage while maintaining drill feed rates up to 100 mm/s.

In medical device assembly, DSMC112 57360001-HC drives the servo motors of a robotic syringe filling system. Its PROFINET interface connects to a central PLC, enabling recipe-based control of filling volumes with ±0.1% accuracy. The controller’s quick response to pressure feedback ensures precise liquid dispensing, even when handling viscous materials like adhesives or pharmaceuticals. During changeover between syringe sizes, auto-tuning reduces setup time by 70% compared to manual tuning methods.

ABB DSMC112 57360001-HC

Related model recommendations

DSMC106 57360001-HC: A lower-current variant of DSMC112 57360001-HC with 6 A continuous output, ideal for small-scale precision applications like lab automation.

DSMC220 57360002-HC: A higher-power model with 20 A continuous output, suitable for heavy-duty applications requiring DSMC112 57360001-HC’s performance in larger systems.

M3LR Servo Motor: ABB’s high-torque servo motor perfectly matched to DSMC112 57360001-HC for seamless integration and optimal performance.

EI813F: ABB’s EtherCAT interface module that extends DSMC112 57360001-HC’s communication range in large automation cells.

HMI80: ABB’s touchscreen panel that visualizes real-time data from DSMC112 57360001-HC, allowing operators to adjust parameters and monitor performance.

DSMC-TUNING-KIT: ABB’s software package for advanced tuning of DSMC112 57360001-HC, including vibration analysis and gain optimization tools.

AC500 PLC: ABB’s programmable logic controller that coordinates multiple DSMC112 57360001-HC units in complex motion systems.

Installation, commissioning and maintenance instructions

Installation preparation: Mount DSMC112 57360001-HC on a 35mm DIN rail or panel in a control cabinet with ambient temperature between 0°C and 55°C. Ensure at least 100mm clearance above and below for cooling. Connect 3-phase power using 4mm² cables, with a dedicated 20A circuit breaker upstream. Use shielded twisted-pair cable for encoder connections, grounding the shield at both ends. Required tools include a torque wrench (0.5-1.5 Nm), wire strippers, and a laptop with ABB’s ServoStudio software. Power off all equipment during installation and verify supply voltage matches the controller’s rating.

Maintenance suggestions: Inspect DSMC112 57360001-HC quarterly for loose connections and dust accumulation, cleaning with compressed air if necessary. Check cooling fans (if equipped) monthly to ensure proper operation. Calibrate feedback devices annually using ServoStudio to maintain positioning accuracy. Monitor temperature rise during operation—case temperature should not exceed 70°C. If fault codes appear (e.g., overcurrent), check motor wiring and load conditions before resetting. Replace the controller if faults persist, using only ABB-certified units to ensure compatibility and performance.

Service and guarantee commitment

DSMC112 57360001-HC comes with a 3-year warranty from installation, covering manufacturing defects and ensuring compliance with published performance specifications. ABB guarantees technical support response within 4 hours for critical applications, with on-site service available in 72 hours for qualified customers. The controller includes free access to ServoStudio software for configuration, tuning, and diagnostics. Extended service contracts offer annual preventive maintenance, firmware updates, and priority support, ensuring DSMC112 57360001-HC delivers reliable performance throughout its 10-year design lifespan. Customers receive dedicated online resources, including wiring diagrams, tuning guides, and application notes specific to this model.