Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | ABB DSMB-01C |

| Manufacturer | ABB |

| Product Category | Safety Module (System 800xA HI) |

| Safety Certification | SIL 3 (IEC 61508), SC 3 (IEC 62443) |

| Response Time | ≤ 15 ms (safety function execution) |

| Fault Tolerance | 1oo2 architecture |

| Diagnostic Coverage | >99.2% |

| Communication Protocols | 800xA HI Safety Bus, OPC UA PubSub |

| Cybersecurity | Secure boot, encrypted comms (AES-256) |

| Operating Voltage | 24 V DC ±10% (redundant inputs) |

| Operating Temperature | -40°C to +70°C (conformal coating) |

| MTBF | >150 years (IEC 61709) |

| Vibration Immunity | 5 g (5-150 Hz) per IEC 60068-2-6 |

| Certifications | TÜV Rheinland SIL 3, ATEX/IECEx Zone 1 |

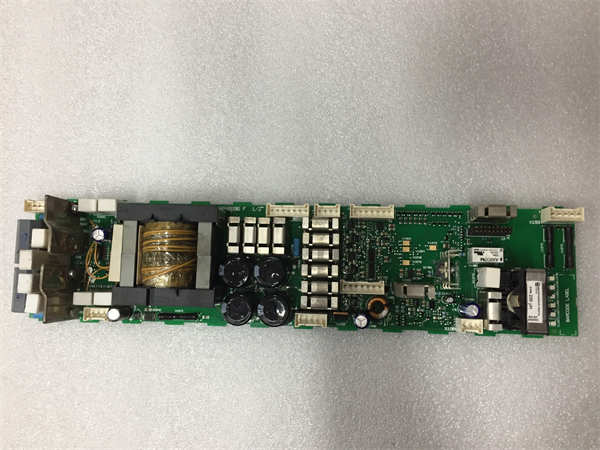

ABB DSMB-01C

Product Introduction

The ABB DSMB-01C is a high-integrity safety module within ABB’s System 800xA High Integrity (HI) platform, engineered for mission-critical safety instrumented systems (SIS) in hazardous processes. As a certified SIL 3 solution, this dual-channel module executes safety logic for emergency shutdown (ESD), fire and gas (F&G), and burner management systems with deterministic sub-20ms response times. The ABB DSMB-01C integrates natively with 800xA’s unified control environment, enabling seamless data exchange between basic process control and safety systems while maintaining rigorous physical/cybersecurity separation.

Featuring proprietary “Diverse Redundancy” technology, the module employs dual dissimilar processors executing independently developed firmware to detect systematic faults. Its integrated safety bus supports peer-to-peer communication between safety modules, eliminating single controller bottlenecks. The ABB DSMB-01C delivers unparalleled value in high-risk industries by reducing spurious trips through advanced diagnostics while maintaining <10⁻9 probability of failure on demand (PFD) – essential for protecting personnel, assets, and environment.

Core Advantages and Technical Highlights

Diverse Redundancy Architecture: Dual ARM Cortex-R4 and R5 processors run dissimilar real-time operating systems with cross-comparison logic. Hardware-based voting detects discrepancies within 3 clock cycles.

Cyber-Resilient Design: Hardware security module (HSM) with cryptographic keys physically fused during manufacturing. Signed firmware updates with chain-of-trust verification. Dynamic port blocking prevents unauthorized access.

Advanced Diagnostics: Continuous memory scrubbing with error-correcting code (ECC). Online circuit supervision detects open wires and short circuits in field devices. Predictive health monitoring of capacitors and voltage regulators.

Deterministic Performance: Safety functions execute in fixed 1ms time slices. Safety bus latency <5ms for 100 nodes. Hot-swap replacement with automatic state synchronization.

Engineering Efficiency: Integrated with 800xA Control Builder for unified engineering. Automatic generation of SIL verification reports per IEC 61511 requirements.

Typical Application Scenarios

In offshore oil platforms, the ABB DSMB-01C manages ESD valves and subsea wellhead controls. Its Zone 1 certification allows installation in hazardous compressor modules, while SIL 3 logic prevents hydrocarbon releases during electrical storms. The module’s -40°C cold-start capability ensures safety functionality during Arctic operations.

For ethylene cracker furnaces, the module executes burner management sequences with 15ms trip response. Diverse redundancy prevents common-cause failures during steam/air ratio upsets. Conformal coating resists corrosion from pyrolysis byproducts.

In LNG liquefaction trains, the ABB DSMB-01C coordinates cryogenic emergency depressurization across multiple safety zones. OPC UA PubSub streams valve position data to cloud-based analytics while maintaining air-gapped safety networks.

ABB DSMB-01C

Related Model Recommendations

ABB DSMF-01C: Foundation Fieldbus safety interface companion

ABB SD831: SIL 3-certified analog input module

ABB ZMU01: Safety power supply module

ABB PM866: Controller for non-safety functions

ABB CI871: PROFINET interface module

ABB SA511F: Safety I/O base unit

ABB TA520: Safety termination assembly

ABB HIC01: Hardware-in-loop tester

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Verify safety network segmentation (TÜV-approved switches). Use double-shielded cables with separate conduits for safety/non-safety signals. Ground cabinet to <0.1Ω resistance. Pre-load safety application in test mode.

Maintenance Suggestions: Perform quarterly diagnostic override tests. Annually validate response times with ABB HIC01 test kit. Monitor “Hardware Degradation Index” – values >90% require preventive replacement. Replace modules after 15 years or during major turnarounds. Firmware updates require TÜV-validated procedures:

Isolate safety functions

Update standby module

Validate checksums

Failover and repeat

Service and Guarantee Commitment

ABB provides a 10-year functional safety warranty for DSMB-01C, including SIL recertification support. Our Safety Excellence Program includes:

24/7 critical response team (4-hour escalation)

Five-year hardware obsolescence guarantee

TÜV-verified firmware update service

SIL verification report renewal

On-demand cybersecurity penetration testing

All modules undergo accelerated lifecycle testing (85°C/85% RH for 1000h) and electromagnetic compatibility testing per IEC 61326-3-1. Third-party SIL 3 certification includes failure modes analysis per IEC 61508-2.