Description

Key Technical Specifications

- Model Number: ABB DSDP170 57160001-ADF

- Manufacturer: ABB

- Input Type: Discrete digital (24V DC sinking, 2-wire/3-wire sensor compatible)

- Number of Input Channels: 32 (individually isolated)

- Input Voltage Range: 19.2V DC to 28.8V DC (24V DC ±10%)

- Input Current: 2.8mA (typical), 4mA (max) per channel

- Operating Temperature: -25°C to 70°C (-13°F to 158°F)

- Storage Temperature: -40°C to 85°C (-40°F to 185°F)

- Isolation: 500V AC (channel-to-channel, channel-to-backplane, 1-minute withstand)

- Response Time: ≤0.1ms (fast mode), ≤1ms (standard mode)

- Power Supply: 24V DC ±10% (21.6V DC to 26.4V DC), from AC 800M backplane

- Power Consumption: 2.5W (standby), 4.8W (full load)

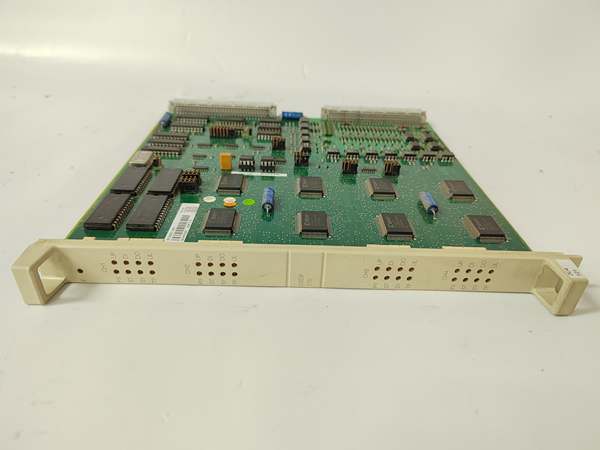

- Mounting: AC 800M I/O rack (compatible with PM850/PM860/PM861/PM865 CPUs)

- Connector Type: 4 x spring-cage terminal blocks (8 channels per block)

- Protection Features: Short-circuit protection (per channel), ESD protection (±15kV air), surge protection (±2kV)

- Compatibility: ABB AC 800M controllers (firmware ≥3.2)

ABB DSDP170 57160001-ADF

Field Application & Problem Solved

In large-scale industrial process control—refineries, automotive assembly plants, and bulk material handling—monitoring dozens to hundreds of discrete sensors requires high-density input modules that balance space efficiency, speed, and reliability. The challenge? Low-density modules consume excessive rack space, forcing oversized control cabinets and increasing wiring complexity. Many high-density modules lack individual channel isolation, causing cross-talk from high-voltage equipment or propagating faults if one sensor shorts. Others have slow response times that miss critical fast-moving sensor states (e.g., high-speed conveyor parts) or fragile terminals that fail under vibration. Third-party modules often struggle with AC 800M backplane synchronization, leading to delayed sensor data that disrupts control logic. The ABB DSDP170 solves these pain points with 32-channel density, individual isolation, fast response, and industrial-grade durability.

You’ll typically find this module in applications like monitoring hundreds of part-present photoeyes in automotive assembly lines, tracking valve position switches in refinery distillation units, or detecting container presence on high-speed packaging lines. It’s a workhorse in large control systems, where its 32-channel design reduces rack space usage by 75% compared to 8-channel modules. In bulk material handling facilities, it monitors conveyor belt safety interlocks and level switches, relying on its 0.1ms fast mode to capture rapid sensor changes. It also excels in brownfield upgrades, adding high-density input capacity to existing AC 800M racks without requiring cabinet redesign.

Its core value is space efficiency and reliable high-volume sensing. The 32-channel density maximizes I/O per rack slot, cutting cabinet footprint and installation costs. Individual channel isolation prevents fault spread and noise interference, while fast response ensures critical sensor states are captured instantly. For plant operators, this means simplified system design, faster troubleshooting, and consistent data from hundreds of sensors—critical in 24/7 environments where sensor downtime halts entire production lines.

Installation & Maintenance Pitfalls (Expert Tips)

- Terminal Block Channel Mapping (Mixing Block Assignments = No Signals): The module uses 4 terminal blocks (8 channels each), but rookies often mix up channel-to-block mapping (e.g., wiring channel 16 to block 3 instead of block 2). This results in no sensor signal, as the PLC expects data from a different terminal. Reference ABB’s wiring diagram: blocks 1-4 correspond to channels 1-8, 9-16, 17-24, 25-32. Label wires with channel numbers and verify against the diagram before powering on.

- Response Mode Overlooking (Standard Mode for Fast Processes): Rookies often leave all channels in standard mode (1ms) for high-speed applications (e.g., 500 parts per minute conveyors). This causes the module to miss rapid sensor triggers, leading to process jams. Configure fast mode (0.1ms) for high-speed sensors via Control Builder M, and reserve standard mode for slow-changing inputs (e.g., E-Stops). Test with a signal generator to confirm 0.1ms detection of short pulses.

- Wire Gauge & Length (Undersized/Long Wires = Voltage Drop): Using 24 AWG wire or runs over 150 meters causes voltage drop below the module’s 19.2V minimum input, leading to no-signal faults. Use 20-18 AWG wire for runs up to 100 meters, and 16 AWG for 100-150 meters. Avoid runs over 150 meters—beyond that, use a signal repeater or remote I/O to maintain voltage integrity.

- Ignoring Short-Circuit Group Alarms (Unaddressed Faults = Module Strain): The module groups channels into 4 alarm zones (8 channels each), but rookies often reset zone alarms without identifying the faulty channel. A persistent short in one channel strains the module’s power circuitry over time. When a zone alarm triggers, use a multimeter to check continuity between each channel’s terminal and ground (a short shows 0Ω). Isolate the faulty sensor/cable, repair it, and clear the alarm—don’t ignore zone alerts.

ABB DSDP170 57160001-ADF

Technical Deep Dive & Overview

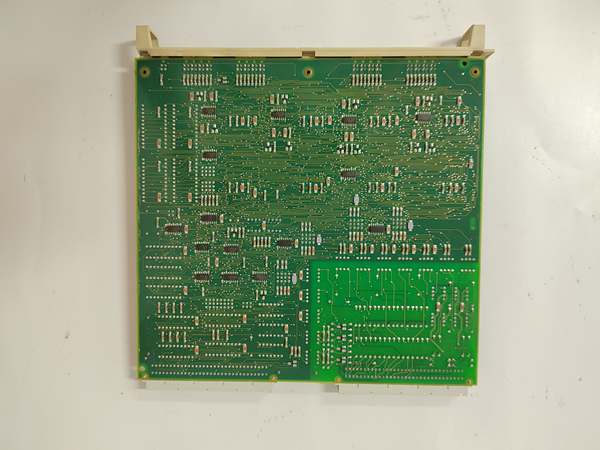

The ABB DSDP170 57160001-ADF is a 32-channel digital input module engineered for high-density discrete sensor monitoring in ABB’s AC 800M control systems. Its core design centers on individually isolated input channels, each protected by 500V AC isolation to block electromagnetic interference (EMI) and prevent fault propagation. This isolation is critical in large industrial facilities, where sensors are often located near motors, transformers, and high-voltage equipment.

The module uses sinking input logic, compatible with most 2-wire and 3-wire 24V DC discrete sensors (proximity switches, photoeyes, limit switches). Per-channel current-limiting resistors and short-circuit protection trigger a diagnostic flag if current exceeds 4mA, shielding the module from wiring mistakes or damaged sensors. ESD (±15kV) and surge (±2kV) protection further enhance durability during installation and operation.

Communication with the AC 800M CPU occurs via the rack’s high-speed backplane bus (100Mbps), enabling real-time data transfer. The module’s internal microcontroller caches input states and updates the CPU at intervals matching the selected response mode (0.1ms fast/1ms standard). This ensures fast response for critical processes while optimizing backplane bandwidth. Configuration settings (response mode, input filtering) are stored in non-volatile memory, retaining data during power loss or module replacement.

Built for industrial ruggedness, the DSDP170 withstands vibration (up to 5g at 10-2000Hz) and temperature extremes (-25°C to 70°C). Its compact 1-slot design maximizes I/O density in AC 800M racks, while four spring-cage terminal blocks simplify organized wiring of 32 channels. Compliance with IEC 61131-2 ensures compatibility with global industrial standards.

As an OEM module, it integrates seamlessly with ABB’s Control Builder M software, supporting drag-and-drop I/O mapping and zone-based diagnostic monitoring. Its focus on high density, isolation, and speed makes it a critical component in large-scale discrete sensing applications where space, reliability, and real-time data are paramount.