Description

Key Technical Specifications

- Model Number: DSDP150

- Manufacturer: ABB Process Automation

- Digital Inputs: 16 channels, 24VDC, sink/source configurable, 3ms response time

- Digital Outputs: 16 channels, 24VDC, solid-state relays (SSR), 0.5A per channel, 8A per module max load

- Isolation Rating: 500V AC (channel-to-channel; DI/DO circuits to backplane)

- Redundancy Support: Yes, compatible with Advant Master redundant controller racks

- Power Supply: 24VDC (from rack backplane; 0.8A max current draw)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Mounting: Rack-mounted (fits Advant Master I/O chassis; hot-swappable)

- Diagnostic Indicators: Front-panel LEDs (per-channel DI/DO status, module power, fault)

- Certifications: UL 508, CSA C22.2 No. 142, CE, ATEX Zone 2 compliant

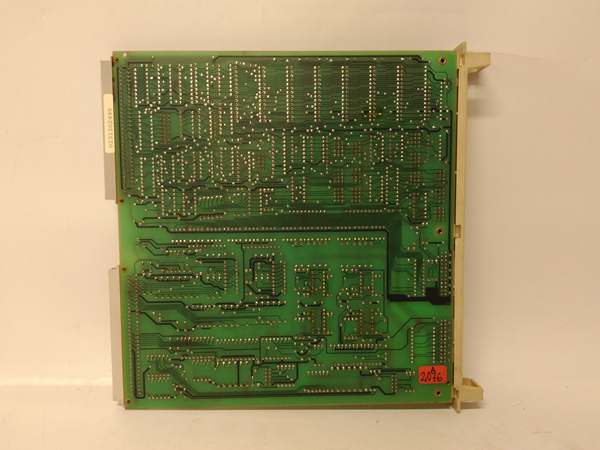

ABB DSDP150

Field Application & Problem Solved

In refineries, pulp mills, and water treatment plants, the biggest pain point with discrete I/O is rack space efficiency—separate DI and DO modules take up twice the slots, increasing rack costs and wiring complexity. Legacy hybrid modules often lack isolation, leading to cross-channel faults when a DO short circuit takes down adjacent DI channels. The DSDP150 solves both problems: it packs 16 DI and 16 DO channels into a single slot, and 500V AC isolation between channels prevents fault propagation. This is a game-changer for high-density motor control centers (MCCs) and valve manifolds where space is at a premium.

You’ll find this module in every Advant Master/800xA DCS installation with discrete control loops—typically monitoring limit switch positions on conveyor belts, pressure switch status on pump skids, and controlling solenoid valves on batch reactor systems. Its core value is density paired with isolation: the 32 total channels per slot cut rack space requirements by 50% compared to separate DI/DO modules, and the isolation ensures a single DO short circuit won’t take down the entire module. I’ve seen a pulp mill reduce MCC rack size by 30% during a retrofit by switching to the DSDP150—freeing up space for future expansion.

Another hidden value is its fast DI response time (3ms). In safety-critical applications like emergency shutdown (ESD) loops, slow response times can mean the difference between a minor fault and a catastrophic event. The DSDP150’s 3ms DI latency ensures ESD signals are detected instantly, triggering shutdowns before damage occurs. For maintenance teams, this means fewer unplanned outages caused by delayed fault detection.

Installation & Maintenance Pitfalls (Expert Tips)

DI Sink/Source Configuration Must Match Field Devices: Rookies often leave DI channels set to the default sink mode and connect source-type sensors (e.g., NPN vs. PNP), resulting in no signal detection. The DSDP150’s DI channels are configurable via DIP switches on the module’s front panel—you must set each channel to sink or source based on the field sensor’s output type. A mismatch will cause DI channels to read “off” permanently, even if the sensor is active. I’ve fixed more DI faults from wrong sink/source settings than any other issue with this module.

DO Load Ratings Are Non-Negotiable for SSR Longevity: The DSDP150’s DO channels use solid-state relays (SSRs) rated for 0.5A per channel and 8A total module load. Rookies often connect 1A solenoid valves directly to the DO channels, burning out SSRs in weeks. Overloading SSRs causes thermal degradation—they start to “stick” on, leading to valve failures and process upsets. Always use external contactors for loads exceeding 0.5A per channel. This is the #1 cause of premature DSDP150 failures in the field.

Hot-Swap Requires Module Deactivation First: The module is hot-swappable, but you can’t just yank it out of a live rack without preparation. First, deactivate the module in the 800xA DCS software to turn off all DO channels—leaving DOs active during swap can cause valves or contactors to stay energized, leading to unsafe process conditions. Then, use the rack’s eject lever to remove the module. This 10-second step prevents equipment damage and safety hazards.

Isolation Testing Is Mandatory After Retrofits: The 500V AC isolation rating degrades over time due to moisture or corrosion, especially in coastal plants. Skip dielectric testing after a retrofit, and a channel-to-channel short could cause a spurious ESD trip (costing $100k+ in downtime). Before commissioning, use a calibrated insulation tester set to 500V AC, test each DI/DO channel against the backplane, and verify isolation resistance ≥100MΩ. If it fails, replace the module—don’t risk a safety system failure.

ABB DSDP150

Technical Deep Dive & Overview

The ABB DSDP150 is a hybrid DI/DO module designed for high-density discrete control in Advant Master and 800xA DCS systems. At its core, it uses two separate circuit banks: one for 16 DI channels (sink/source configurable via DIP switches) and one for 16 DO channels (solid-state relays for silent, spark-free switching). The 500V AC channel-to-channel isolation is achieved via optocouplers, which block electrical current between channels while transmitting digital signals as optical pulses. This design eliminates cross-talk and prevents fault propagation—critical for applications where a single short circuit could disrupt multiple loops.

The module’s redundant backplane support enables seamless integration with Advant Master redundant controllers: if the primary controller fails, the standby controller takes over control of the DSDP150 without interrupting DI/DO signals. The front-panel LEDs provide per-channel status feedback—green for active DI/DO, red for fault—so technicians can troubleshoot without opening the DCS software. This is a lifesaver for remote sites where HMI access is limited.

Unlike electromechanical relay outputs, the DSDP150’s SSRs have no moving parts, reducing wear and tear and extending service life to 10+ years. However, SSRs are sensitive to overheating—this is why the module has a total load limit of 8A. Exceeding this limit causes the SSRs to overheat and fail, which is why external contactors are mandatory for high-load devices.

In the field, this module’s strength is its versatility and reliability. It’s the go-to hybrid I/O module for Advant systems because it saves rack space, reduces wiring complexity, and provides robust isolation. Install it correctly, respect the load ratings, and it will run for decades without intervention—making it a staple in discrete process control applications.