Description

Key Technical Specifications

- Model Number: ABB DSDP150

- Manufacturer: ABB

- Input Type: Discrete digital (24V DC sinking, 2-wire sensor compatible)

- Number of Input Channels: 16 (individually isolated)

- Input Voltage Range: 19.2V DC to 28.8V DC (24V DC ±10%)

- Input Current: 3mA (typical), 5mA (max) per channel

- Operating Temperature: -25°C to 70°C (-13°F to 158°F)

- Storage Temperature: -40°C to 85°C (-40°F to 185°F)

- Isolation: 500V AC (channel-to-channel, channel-to-backplane, 1-minute withstand)

- Response Time: ≤0.1ms (fast mode), ≤1ms (standard mode)

- Power Supply: 24V DC ±10% (21.6V DC to 26.4V DC), from AC 800M backplane

- Power Consumption: 1.0W (standby), 1.8W (full load)

- Mounting: AC 800M I/O rack (compatible with PM850/PM860/PM861/PM865 CPUs)

- Connector Type: 2 x spring-cage terminal blocks (8 channels per block)

- Protection Features: Short-circuit protection (per channel), ESD protection (±15kV air)

- Compatibility: ABB AC 800M controllers (firmware ≥3.2)

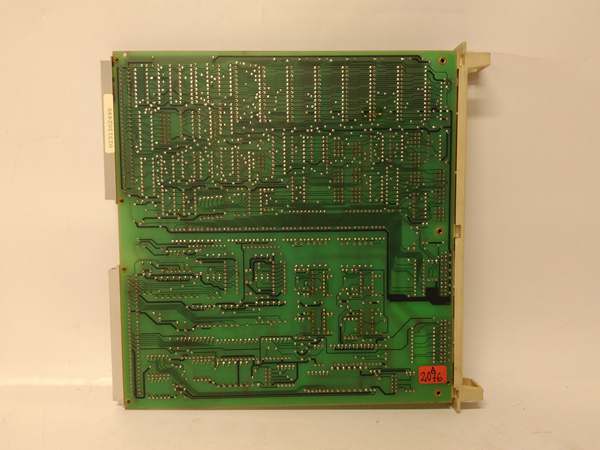

ABB DSDP150 57160001-GF

Field Application & Problem Solved

In industrial process control—manufacturing lines, water treatment plants, and refineries—monitoring discrete sensors (limit switches, emergency stops, photoeyes) requires reliable input modules that handle noise, fast state changes, and fault isolation. The challenge? Many digital input modules lack channel isolation, causing cross-talk from high-voltage equipment or propagating faults across all channels if one sensor shorts. Others have slow response times that miss critical sensor state changes (e.g., a jammed part in a conveyor) or lack robust protection against short circuits. Third-party modules often fail to sync with the AC 800M backplane, leading to delayed data transmission and control logic errors. The ABB DSDP150 solves these pain points with isolated channels, fast response, and industrial-grade protection.

You’ll typically find this module in applications like detecting part presence with photoeyes in automotive assembly lines, monitoring valve position switches in chemical reactors, or triggering emergency stop circuits in power plant auxiliary systems. It’s a staple in high-speed production environments (e.g., packaging lines), where its 0.1ms fast mode captures rapid sensor changes to prevent process jams. In wastewater treatment plants, it monitors pump run/stop status and level switch triggers, relying on channel isolation to withstand noise from motor drives. It also excels in retrofits of older AC 800M systems, upgrading input capacity to support new sensors without replacing the entire control infrastructure.

Its core value is reliability and speed in discrete sensing. Channel isolation prevents a single sensor short from disabling the entire module, a common failure point in non-isolated alternatives. The fast response time ensures critical sensor states are captured instantly, avoiding process delays or safety risks. For plant operators, this means consistent sensor data, faster fault diagnosis, and minimized downtime—critical in 24/7 industrial environments where missed sensor signals can halt production lines.

Installation & Maintenance Pitfalls (Expert Tips)

- Sensor Wiring Polarity (Reverse Wiring = No Signal): The module uses sinking inputs, but rookies often reverse the sensor’s power and signal wires. For 2-wire sensors, the positive (+) lead connects to 24V DC power, and the negative (-) lead connects to the module’s input terminal. Reverse wiring results in no input signal, even if the sensor is active. Use a multimeter to verify voltage at the input terminal when the sensor is triggered—you should see 0V DC (sinking) for an active signal, 24V DC for inactive.

- Response Mode Mismatch (Standard vs. Fast): The module supports standard (1ms) and fast (0.1ms) response modes, but rookies often leave it in standard mode for high-speed applications. This causes the module to miss rapid sensor state changes (e.g., a fast-moving part triggering a photoeye). Configure the mode in Control Builder M: use fast mode for high-speed processes (packaging, assembly lines) and standard mode for slow-changing sensors (limit switches, E-Stops). Test response time with a signal generator to confirm it matches process requirements.

- Terminal Block Overcrowding (Poor Wire Management = Shorts): The module’s spring-cage terminals are compact, but rookies often cram multiple wires into a single terminal or leave exposed wire strands. This causes short circuits between adjacent channels, leading to false input triggers. Use one wire per terminal, strip wires to 8-10mm (per ABB specs), and use ferrules on stranded wire to prevent fraying. Leave 5-10mm of space between wires in the terminal block to avoid contact.

- Ignoring Short-Circuit Alarms (Unaddressed Faults = Module Damage): The module’s per-channel short-circuit protection triggers an alarm, but rookies often ignore it or reset it without troubleshooting. A short-circuit (e.g., a damaged sensor cable) strains the module’s input circuitry over time, reducing lifespan. When an alarm occurs, disconnect the affected channel’s sensor, use a multimeter to check for continuity between the input terminal and ground (a short will show 0Ω), and repair or replace the sensor/cable before re-enabling the channel.

ABB DSDP150 57160001-GF

Technical Deep Dive & Overview

The ABB DSDP150 is a 16-channel digital input module engineered for discrete sensor monitoring in ABB’s AC 800M control systems. Its core design centers on isolated, high-speed input circuitry that converts physical sensor states (on/off) into digital signals the AC 800M CPU can process for control logic. Each channel is electrically isolated with 500V AC rating, achieved via optocouplers that separate the sensor circuit from the module’s internal electronics and backplane. This isolation blocks electromagnetic interference (EMI) from motors, transformers, and high-voltage equipment, ensuring clean sensor data.

The module’s input circuitry uses sinking logic, where the sensor completes the ground path when active. This is compatible with most industrial 2-wire and 3-wire discrete sensors (proximity switches, photoeyes, limit switches). A built-in current-limiting resistor (per channel) protects against short circuits, triggering a diagnostic flag if current exceeds 5mA. ESD protection (±15kV air discharge) shields the module from static damage during installation or maintenance.

Communication with the AC 800M CPU occurs via the rack’s high-speed backplane bus (100Mbps), enabling real-time data transfer. The module’s internal microcontroller caches input states and updates the CPU at intervals matching the selected response mode (0.1ms or 1ms). Configuration (response mode, input filtering) is stored in non-volatile memory, retaining settings during power loss or module replacement.

Built for industrial ruggedness, the DSDP150 withstands vibration (up to 5g at 10-2000Hz) and temperature extremes (-25°C to 70°C), making it suitable for harsh plant floors and outdoor skids. The spring-cage terminals simplify tool-less wiring, reducing installation time and human error. Its compact 1-slot design maximizes I/O density in AC 800M racks, while compliance with IEC 61131-2 ensures compatibility with global industrial standards.

As an OEM module, it integrates seamlessly with ABB’s Control Builder M software, supporting drag-and-drop I/O mapping and diagnostic monitoring. The module’s focus on reliability—isolated channels, robust protection, and fast response—makes it a critical component in discrete sensing applications where accurate, timely sensor data is essential for process control and safety.