Description

Key Technical Specifications

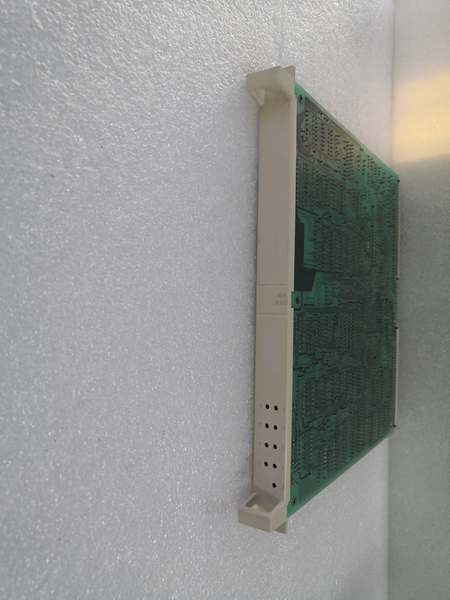

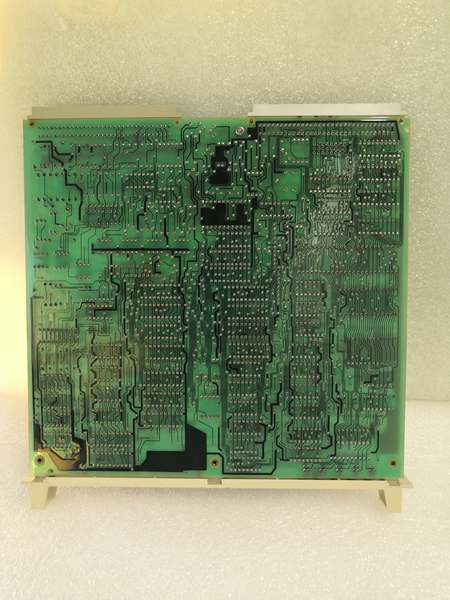

- Model Number: ABB DSDP140A

- Manufacturer: ABB

- Primary Function: Pulse counting (encoder input) + mixed discrete/analog I/O

- Encoder Input Channels: 3 (position loop inputs), ±15mA current range

- Max Pulse Frequency: 80kHz (encoder inputs)

- Digital I/O: 2 digital inputs (DI, 24V DC sinking), 4 digital outputs (DO, 24V DC sourcing)

- Analog Output: 1 AO (11-bit + sign resolution, 0-10V DC or 0-±20mA configurable)

- Operating Temperature: -20°C to 70°C (-4°F to 158°F); extended range -40°C to 85°C (select models)

- Storage Temperature: -40°C to 85°C (-40°F to 185°F)

- Isolation: 500V AC (channel-to-channel, channel-to-backplane, 1-minute withstand)

- Power Supply: 24V DC ±10% (21.6V DC to 26.4V DC), from AC 800M backplane

- Power Consumption: 2.1W (standby), 3.5W (full load)

- Mounting: AC 800M I/O rack (compatible with PM850/PM860/PM861/PM865 CPUs)

- Connector Type: DIN 密集型连接器 (Dense DIN connector) + RS-485 terminal block

- Compatibility: ABB AC 800M controllers (firmware ≥3.0)

ABB DSDP140B

Field Application & Problem Solved

In industrial motion control—conveyor systems, robotic arms, and precision manufacturing—tracking position, speed, or rotation via encoders requires modules that combine high-speed pulse counting with flexible I/O. The challenge? Standalone pulse counters lack integrated I/O, forcing users to install separate modules for sensor monitoring and actuator control. Many low-cost counters can’t handle 80kHz pulse frequencies from high-speed encoders, leading to missed counts and position errors. Others lack electronic isolation, causing noise-induced counting glitches in harsh industrial environments. Third-party modules often fail to sync with the AC 800M backplane, resulting in delayed position data that disrupts closed-loop control. The ABB DSDP140A solves these pain points with high-speed counting, integrated I/O, and robust isolation.

You’ll typically find this module in applications like tracking conveyor belt speed via incremental encoders in logistics facilities, providing position feedback for robotic arm joints in automotive assembly, or monitoring motor rotation in packaging machinery. It’s a critical component in precision motion control systems (e.g., CNC routers, printing presses), where its 80kHz frequency handling ensures accurate count capture even at high speeds. In power plants, it’s used to monitor turbine rotor position via encoders, relying on its extended temperature range to withstand harsh generator room conditions. It also excels in retrofits, replacing outdated counter modules while adding mixed I/O to support new sensors and actuators.

Its core value is integration and precision. By combining pulse counting, DI/DO, and AO in a single slot, it reduces rack space and wiring complexity. The 80kHz max frequency handles high-speed encoders, while electronic isolation eliminates noise-related counting errors. For operators, this means accurate position/speed data, simplified system design, and reliable closed-loop control—critical in applications where even small counting errors lead to product defects or equipment damage.

Installation & Maintenance Pitfalls (Expert Tips)

- Encoder Wiring Polarity (Signal Reversal = Count Errors): Rookies often swap the A/B phase wires of incremental encoders, causing the module to count in reverse or miss pulses. This leads to incorrect position/speed readings that disrupt control logic. Follow ABB’s wiring diagram: connect encoder phase A to channel 1, phase B to channel 2, and index (if used) to channel 3. Use a oscilloscope to verify pulse alignment—phase A should lead phase B by 90° for forward rotation.

- Input Filter Misconfiguration (Noise = False Counts): The module’s programmable input filter is critical for suppressing noise, but rookies often set it too low (for fast signals) or too high (for slow signals). A filter setting too low allows electrical noise to trigger false counts; too high misses valid pulses from high-speed encoders. Match the filter to the encoder’s pulse frequency: use 1µs for 80kHz signals, 10µs for 10kHz signals. Test with a signal generator to confirm no false counts or missed pulses.

- AO Range Mismatch (Incorrect Output = Actuator Misalignment): The analog output is configurable for 0-10V or 0-±20mA, but rookies often set it to the wrong range for the connected actuator. Using 10V output for a 20mA actuator results in insufficient drive signal, causing incorrect positioning. Configure the AO range in Control Builder M to match the actuator’s input requirements. Test with a multimeter: simulate a full-scale count and confirm the AO outputs 10V or 20mA as configured.

- RS-485 Termination (Missing Resistor = Communication Drops): The module’s RS-485 port requires a 120Ω termination resistor for long cable runs (over 50 meters), but rookies often omit it. This causes signal reflections, leading to intermittent communication with the AC 800M controller. Install a 120Ω resistor between the RS-485 + and – terminals at the module end. For multi-module RS-485 networks, add a resistor only at the two ends of the bus to avoid signal degradation.

ABB DSDP140B

Technical Deep Dive & Overview

The ABB DSDP140A is a multi-function module engineered for pulse counting and mixed-signal control in ABB’s AC 800M systems. Its core design centers on a high-speed counter circuit that processes up to 80kHz pulses from incremental encoders, converting rotational or linear motion into digital count data for the AC 800M CPU. Three dedicated encoder channels handle position loop feedback, with electronic isolation (500V AC) to block electromagnetic interference from motors and drives.

The module’s integrated I/O expands its utility: 2 digital inputs monitor sensor states (e.g., limit switches), 4 digital outputs trigger actuators (e.g., brakes), and 1 analog output provides proportional control signals (e.g., speed reference for variable-frequency drives). The 11-bit + sign AO resolution ensures precise actuator control, while configurable range (0-10V/0-±20mA) supports diverse field devices.

Communication with the AC 800M CPU occurs via the rack’s high-speed backplane bus (100Mbps), enabling real-time transfer of count data and I/O states. The module’s internal microcontroller caches count values and updates the CPU at 1ms intervals, ensuring closed-loop control responsiveness. A programmable input filter suppresses noise, with settings adjustable via Control Builder M to match encoder frequency.

Built for industrial ruggedness, the DSDP140A withstands vibration (up to 5g at 10-2000Hz) and temperature extremes (extended range -40°C to 85°C for harsh environments). The dense DIN connector and RS-485 terminal block simplify wiring, while compliance with IEC 61131-2 ensures compatibility with global industrial standards.

As an OEM module, it integrates seamlessly with ABB’s Control Builder M software, supporting drag-and-drop configuration of counter modes (up/down, reset, latch) and I/O mapping. Its combination of high-speed counting and mixed I/O makes it a versatile solution for motion control applications where precision, integration, and reliability are paramount.