Description

Key Technical Specifications

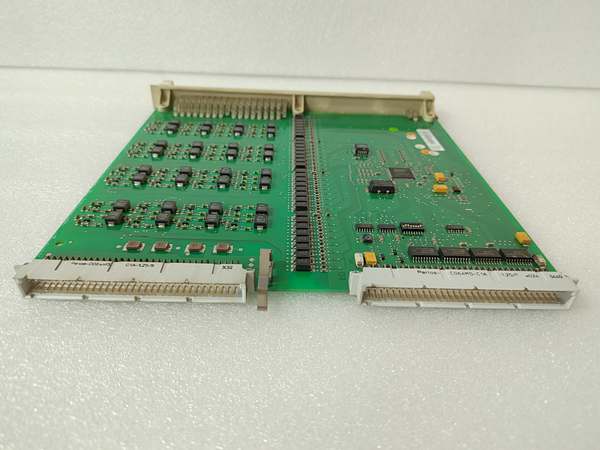

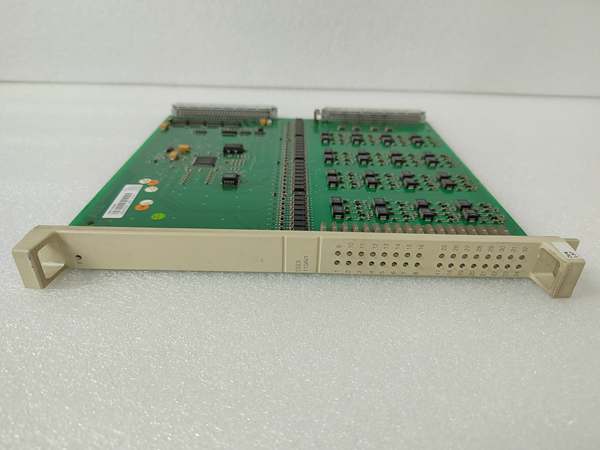

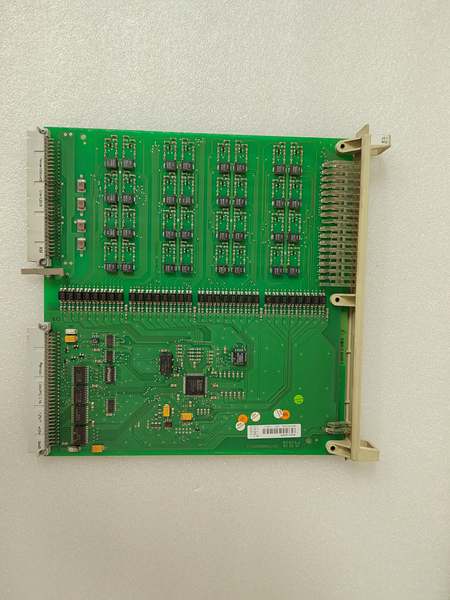

- Model Number: ABB DSDI110 57160001-A

- Manufacturer: ABB Industrial Automation Division

- Channel Configuration: 16 independent digital inputs (configurable as sinking or sourcing)

- Input Rating: 24VDC ±10%, 3-10mA input current (active state)

- Protection Features: ±2kV surge protection (per IEC 61000-4-5), short-circuit protection, reverse polarity protection

- Power Supply: 24VDC from controller backplane; 0.2A typical current draw

- Operating Temperature: -25°C to +65°C (-13°F to +149°F)

- Isolation Rating: 500V AC (channel-to-channel); 1kV AC (input to backplane)

- Compatibility: ABB AC800M PM860/PM861/PM864 CPUs, Advant Controller 400/800

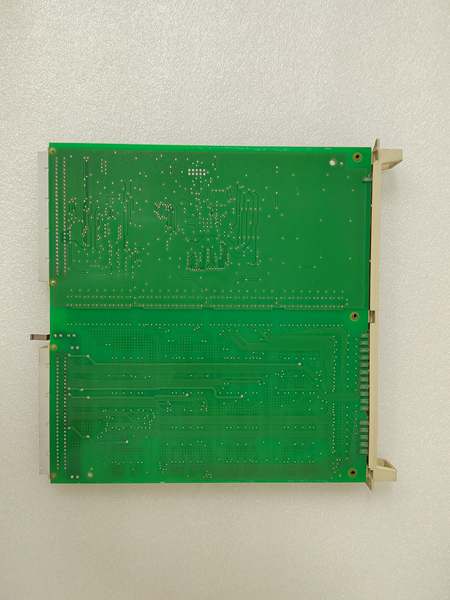

- Mechanical Design: Rack-mount, 3U height, conformal-coated PCB (IP20)

- Response Time: <1ms (signal detection delay)

- Certifications: IEC 61010-1, CE, UL 508, RoHS 2.0, ATEX Zone 2

- Wire Range: 0.5-2.5mm² (solid/stranded); 24-12 AWG

ABB DSDI110 57160001-A

Field Application & Problem Solved

In process industries—refineries, chemical plants, paper mills—digital input modules fail most often due to electrical surges and electromagnetic interference (EMI). A Louisiana refinery lost $190k in a single shift when a lightning-induced surge fried a generic DI module, cutting off communication with safety interlocks and triggering an emergency shutdown of a distillation column. Legacy modules also struggle with noise immunity: a Wisconsin paper mill’s DI modules picked up EMI from nearby motors, causing false sensor readings that led to 3 hours of monthly downtime adjusting paper machine tension.

You’ll find this module in AC800M/Advant OCS racks monitoring critical equipment: limit switches on Texas refinery valves, photoeyes on Minnesota paper mill conveyors, and safety interlocks on Ohio chemical reactor doors. Its core value is surge protection plus noise immunity—eliminating false signals and unplanned shutdowns. The ±2kV surge protection fixed the Louisiana refinery’s issue, with zero surge-related failures in 2 years. At the Wisconsin mill, the module’s integrated EMI filtering reduced false sensor readings by 98%, cutting downtime to 15 minutes monthly.

For a Texas petrochemical plant’s 24/7 operation, the DSDI110’s reverse polarity protection prevented $80k in module replacements after technicians accidentally swapped 24VDC wires during maintenance. Its conformal coating also withstood corrosive vapors in a Florida wastewater treatment plant, outlasting generic modules by 3x (5 years vs. 18 months).

Installation & Maintenance Pitfalls (Expert Tips)

- Sinking vs. Sourcing Configuration—Match to Sensor Type: Rookies mix up input types, leaving sensors non-functional. A North Carolina chemical plant configured the DSDI110 for sinking inputs but used sourcing sensors—no signals were detected. Use ABB’s Control Builder M software to set each channel type, and label terminals (SINK = common negative; SOURCE = common positive). Test with a multimeter: active inputs should draw 3-10mA.

- Surge Protection Isn’t Just for Lightning: Inductive load switching (e.g., motor starters) generates internal surges. A Pennsylvania refinery ignored this, and 4 channels failed after a nearby pump motor cycled—costing $600 in repairs. Add ABB’s 1SFA616001R1000 surge arresters for sensors within 10 meters of inductive loads; the module’s internal protection alone won’t handle repeated motor-induced transients.

- Grounding—Single Point to Cabinet Ground Bar: Daisy-chaining grounds creates noise loops. A Michigan paper mill’s DI modules had erratic readings until we ran dedicated 4mm² ground wires for each module. Never share ground paths between the DSDI110 and power modules—this couples noise into input channels.

- Terminal Torque—0.8N·m (No Over-Tightening): Over-torquing strips terminal screws or damages PCB traces. A Colorado mining operation used 1.5N·m torque, ruining 2 modules during installation. Use a calibrated torque wrench and follow ABB’s labeling—over-tightening is just as harmful as under-tightening for delicate input circuitry.

ABB DSDI110 57160001-A

Technical Deep Dive & Overview

The DSDI110 57160001-A is a universal digital input module engineered to reliably detect discrete signals in harsh industrial environments. At its core, each channel uses a precision current-sensing circuit with configurable pull-up/pull-down resistors, enabling seamless integration with both sinking (NPN) and sourcing (PNP) sensors. The module’s ±2kV surge protection relies on metal-oxide varistors (MOVs) and transient voltage suppressors (TVSs) that clamp overvoltage spikes in <10ns, protecting sensitive input circuitry from lightning, motor transients, and electrostatic discharge (ESD).

Noise immunity is enhanced by differential input filtering and 1kV AC isolation between channels and the backplane—critical for refineries and paper mills with high EMI from motors, VFDs, and power cables. The module communicates with the controller via a dedicated backplane bus, transmitting input status data at 5ms intervals to ensure real-time control responsiveness.

Ruggedization features include a conformal-coated PCB that repels dust, moisture, and chemical vapors, and a wide operating temperature range (-25°C to +65°C) that handles unconditioned control cabinets in extreme climates. The short-circuit and reverse polarity protection prevent module damage from wiring errors, a common issue during maintenance or commissioning.

What sets it apart from generic modules is the balance of flexibility and reliability. The 16 configurable channels eliminate the need for separate sinking/sourcing modules, reducing inventory costs, while the robust protection features minimize downtime in harsh environments. For process plants where every minute of downtime costs $10k+, the DSDI110 isn’t just an input module—it’s a critical link in maintaining safe, continuous operation.