Description

Key Technical Specifications

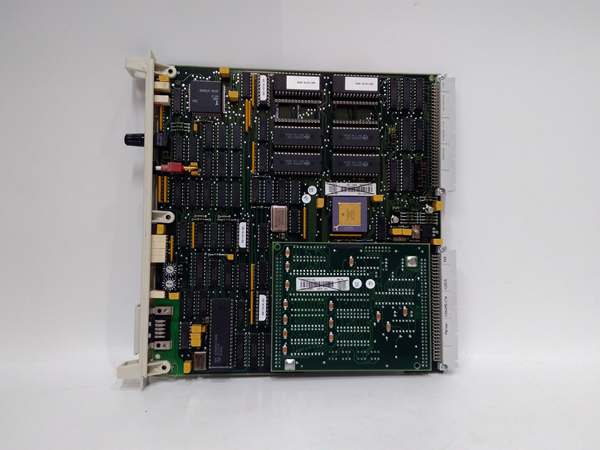

- Model Number: DSCS150 5752001-FY

- Manufacturer: ABB

- Protocol Support: GCOM, Modbus RTU, PROFINET, Ethernet/IP, CANopen (configurable)

- Ports: 2 x Gigabit Ethernet (RJ45), 1 x RS-232, 1 x RS-485, GCOM bus interface

- Processor: 32-bit RISC (400MHz clock speed)

- Memory: 256MB RAM, 128KB SRAM (battery-backed)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Isolation: 2kV AC (network ports to backplane, serial to power)

- Power Supply: 24V DC (5W typical, 18–30V DC operating range)

- I/O Expansion: Supports up to 7 external I/O modules (via FBP bus adapter)

- Dimensions (W x H x D): 297mm x 36mm x 175mm (standard variant)

- Weight: Approx. 0.6kg

- Mounting: Rack-mount (Advant Master I/O rack) or DIN rail (35mm, compact variant)

- Protection Features: ESD protection (±15kV), watchdog timer, battery-backed critical data

- Compliance: IEC 61158 (fieldbus), IEC 61000-4 (EMC), UL 508

ABB DSCS150 5752001-FY

Field Application & Problem Solved

In legacy and hybrid industrial control systems—refineries, power plants, and chemical plants running ABB Advant Master or AC 800M DCS—the biggest challenge is unifying communication between GCOM networks, modern Ethernet-based devices, and legacy serial equipment. Traditional gateways lack multi-protocol flexibility, suffer from slow data transfer, or can’t expand to support additional I/O, leading to communication silos, data bottlenecks, and unplanned downtime. This module solves that by acting as a universal bridge, combining GCOM native support with multi-protocol compatibility and I/O expansion—eliminating the need for multiple specialized gateways.

You’ll typically find this module linking AC 800M DCS systems to GCOM-enabled field devices: refinery distillation column pressure transmitters, power plant boiler feedwater flow meters, or chemical plant reactor temperature sensors. It’s also used in pulp mills, connecting legacy RS-485 Modbus sensors to modern PROFINET PLCs, and in water treatment plants, bridging CANopen valve controllers to the central DCS. For retrofits, it’s a drop-in upgrade for outdated GCOM gateways, adding Ethernet connectivity and I/O expansion without replacing existing field wiring—critical for facilities looking to modernize without costly overhauls.

Its core value is versatility and reliability. The 400MHz processor handles high-volume data transfer without latency, while battery-backed SRAM preserves critical configuration and status data during power outages. The ability to expand to 7 I/O modules eliminates the need for additional communication hardware, simplifying system design. For plant operators, this translates to centralized control over diverse devices, faster fault diagnosis, and extended lifespan for legacy systems—critical in industries where replacing entire DCS infrastructure is impractical or too costly.

Installation & Maintenance Pitfalls (Expert Tips)

FBP Bus Adapter Compatibility: Don’t Mix Generations

Rookies often use outdated FBP bus adapters when expanding I/O modules, leading to communication failures with the gateway. The module requires a compatible FBP adapter (matching Advant Master/AC 800M generation) to recognize external I/O. Verify the adapter’s part number against ABB’s compatibility matrix before installation. Using an incompatible adapter will result in unrecognized modules and wasted troubleshooting hours.

Battery Backup: Replace Before Failure

The module’s 128KB SRAM relies on a backup battery to retain critical data during power loss, but technicians frequently ignore battery replacement. A dead battery erases configurations and status data, forcing a full reconfiguration after power restoration. Replace the battery every 3–5 years (per ABB’s recommendation) or whenever the low-battery alert appears in the DCS. Mark replacement dates on the module to avoid oversight—this is a cheap preventive measure that avoids costly downtime.

Protocol Stack Overloading: Disable Unused Protocols

Enabling all supported protocols (GCOM, Modbus, PROFINET, Ethernet/IP) simultaneously overloads the processor, increasing latency and causing data drops. Rookies leave all protocols active “just in case,” but this degrades performance. Enable only the protocols required for your application (e.g., GCOM + Modbus RTU for legacy sensors, PROFINET for modern PLCs). Monitor CPU usage via the web interface—keep it below 70% to maintain real-time data transfer.

Ethernet Cabling: Shielding for High-EMI Areas

In refineries or power plants, using unshielded Ethernet cables exposes the module to EMI from motors, transformers, or switchgear. This causes packet loss and protocol errors, even with 2kV isolation. Use shielded Cat6 cable for all Ethernet runs, and ground the shield at the control cabinet end. Keep Ethernet cables at least 20cm (8 inches) away from power cables—unshielded cables in high-EMI zones will experience 30%+ packet loss, leading to false device disconnect alarms.

ABB DSCS150 5752001-FY

Technical Deep Dive & Overview

The ABB DSCS150 5752001-FY is a multi-protocol communication gateway engineered to unify diverse industrial networks and expand I/O capabilities in harsh process environments. At its core, the 400MHz RISC processor acts as a data router and protocol translator, handling simultaneous communication across GCOM, Ethernet, and serial networks without bottlenecks. Dedicated hardware offloads protocol processing, ensuring low latency (sub-10ms) for time-sensitive control data.

The module’s memory architecture includes battery-backed SRAM to preserve critical configuration data and device status during power outages—a critical feature for 24/7 industrial operations. The dual Ethernet ports support link aggregation for redundant connections, while the RS-232/RS-485 ports handle legacy serial devices. The GCOM bus interface provides native compatibility with ABB’s Advant Master systems, enabling seamless integration with existing GCOM field devices.

I/O expansion is enabled via an optional FBP bus adapter, allowing the module to act as a distributed I/O controller for up to 7 external modules. This eliminates the need for separate communication links to remote I/O racks, reducing wiring complexity and failure points. The built-in web server simplifies configuration—technicians can set up protocols, map I/O, and monitor status without specialized software, saving time during installation and maintenance.

Ruggedness is built for industrial floors: the wide operating temperature range and 2kV isolation withstand electrical transients and harsh ambient conditions. The watchdog timer triggers a reset if the processor locks up, preventing system hangs. Overall, this module is a workhorse for hybrid control systems, delivering the flexibility to connect legacy and modern devices while providing the reliability needed for critical process control.