Description

Key Technical Specifications

- Model Number: ABB DSCS131 57310001-LM

- Manufacturer: ABB

- Communication Ports: 2 x RS-485 (half-duplex, isolated)

- Supported Protocols: Modbus RTU (master/slave modes), ABB DriveBus

- Baud Rate Range: 1200 bps to 115200 bps (software-configurable)

- Data Format: 7/8 data bits, 1/2 stop bits, even/odd/no parity (configurable)

- Operating Temperature: -25°C to 70°C (-13°F to 158°F)

- Storage Temperature: -40°C to 85°C (-40°F to 185°F)

- Isolation: 1kV AC (port-to-port, port-to-backplane, 1-minute withstand)

- Transmission Distance: Up to 1200 meters (per RS-485 port)

- Power Supply: 24V DC ±10% (21.6V DC to 26.4V DC), from AC 800M backplane

- Power Consumption: 1.2W (standby), 2.0W (full load)

- Mounting: AC 800M I/O rack (compatible with PM850/PM860/PM861/PM865 CPUs)

- Connector Type: 2 x spring-cage terminal blocks (A/B/GND per port)

- Protection Features: Surge protection (±15kV ESD), short-circuit protection on RS-485 lines

- Compatibility: ABB AC 800M controllers (firmware ≥3.1)

ABB DSCS131 57310001-LM

Field Application & Problem Solved

In industrial process control—refineries, water treatment plants, and manufacturing facilities—legacy serial devices (flow meters, pressure sensors, older drives) remain critical but lack Ethernet connectivity. The challenge? Integrating these devices with modern AC 800M PLCs requires reliable serial-to-backplane communication that avoids data loss or noise interference. Many single-port modules force daisy-chaining dozens of devices, leading to communication bottlenecks and difficult troubleshooting. Low-cost serial modules lack port isolation, causing cross-talk between networks or damage from voltage transients. Third-party modules often fail to support Modbus RTU master mode, limiting control over legacy devices. The ABB DSCS131 solves these pain points with dual isolated ports, Modbus RTU flexibility, and industrial-grade protection.

You’ll typically find this module in applications like connecting Modbus RTU flow meters to AC 800M controllers in chemical plants, integrating legacy variable-speed drives with modern SCADA in pulp mills, or linking pressure sensors to PLCs in water treatment facilities. It’s a staple in brownfield upgrades, where it bridges the gap between new AC 800M systems and existing serial devices—eliminating the need for costly device replacements. In power plant auxiliary systems, it’s used to communicate with battery chargers and temperature monitors, relying on its 1200-meter transmission range to cover large facilities. It also excels in multi-network setups, where its dual ports separate critical (e.g., safety sensors) and non-critical (e.g., data loggers) devices for improved reliability.

Its core value is seamless legacy integration and network resilience. Dual isolated ports prevent cross-network interference and allow separate device groups, while Modbus RTU master/slave support ensures control over and from legacy equipment. For operators, this means extended life for existing devices, reduced capital costs, and reliable data transfer—critical in industries where replacing legacy systems is prohibitively expensive or disruptive.

Installation & Maintenance Pitfalls (Expert Tips)

- RS-485 Wiring Topology (Daisy-Chain vs. Star): Rookies often use star topology (all devices connected directly to the module) instead of daisy-chain, causing signal reflections and communication drops. RS-485 requires a linear daisy-chain: connect the first device to the module, the second to the first, and so on. Avoid branching wires—this creates impedance mismatches. Install a 120Ω termination resistor at the first and last devices in the chain (not at the module) to absorb reflections.

- Baud Rate/Parity Mismatch (Configuration Inconsistency = No Communication): The module and connected devices must have identical baud rate, data bits, stop bits, and parity settings, but rookies often mix configurations. A 9600 bps module paired with a 4800 bps sensor results in garbled data or no connection. Document all device settings first, then configure the module via Control Builder M to match. Test communication with a Modbus scanner tool to verify data exchange before integrating with the PLC.

- Grounding Errors (Common Ground = Noise): RS-485 is differential, but rookies often connect the module’s GND terminal to different ground points than devices. This creates ground loops, introducing noise that corrupts data. Connect the module’s GND terminal to the same common ground as all serial devices. Use shielded twisted-pair (STP) cable, and ground the shield at the module end only (single-point grounding) to avoid additional loops.

- Overloading the Bus (Exceeding Device Limit): Each RS-485 port supports up to 32 devices (per ABB specs), but rookies often connect 40+ devices to a single port. This exceeds the bus’s load capacity, causing signal degradation and intermittent communication. Split devices across the module’s two ports if counts exceed 32. For large networks (33-64 devices), use a RS-485 repeater to boost the signal and isolate bus segments.

ABB DSCS131 57310001-LM

Technical Deep Dive & Overview

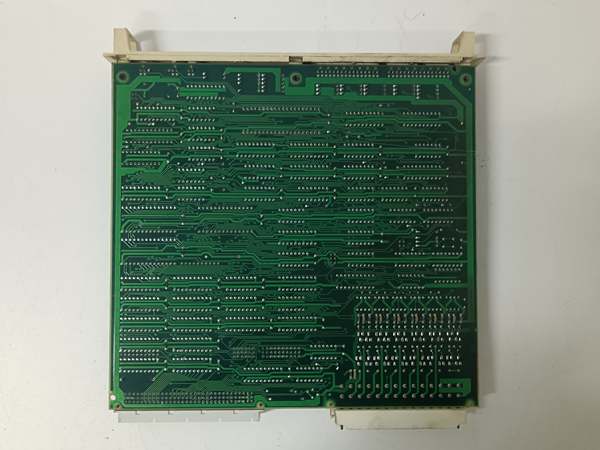

The ABB DSCS131 57310001-LM is a dual-port RS-485 serial communication module engineered to integrate legacy devices with ABB’s AC 800M control systems. Its core design centers on two isolated serial ports, each capable of independent configuration for Modbus RTU master or slave mode. This flexibility allows the module to either control legacy devices (master mode) or transmit PLC data to serial-based systems (slave mode).

Each RS-485 port features 1kV AC isolation from the other port and the AC 800M backplane, achieved via optocouplers and isolated power supplies. This isolation blocks electromagnetic interference (EMI) from motors, transformers, and high-voltage equipment—common in refineries and manufacturing plants—and prevents fault propagation between ports. Surge protection (±15kV ESD) and short-circuit protection shield the module from wiring mistakes and voltage transients.

Communication with the AC 800M CPU occurs via the rack’s high-speed backplane bus (100Mbps), enabling real-time transfer of serial data. The module’s internal microcontroller handles Modbus RTU frame encoding/decoding, reducing CPU load by offloading serial communication tasks. Baud rates (1200-115200 bps) and data formats are configurable via Control Builder M, with settings stored in non-volatile memory.

Built for industrial ruggedness, the DSCS131 withstands vibration (up to 5g at 10-2000Hz) and temperature extremes (-25°C to 70°C). The spring-cage terminal blocks simplify wiring, while the module’s compact 1-slot design maximizes I/O density in AC 800M racks. Compliance with Modbus RTU standards ensures compatibility with thousands of legacy serial devices, from flow meters to variable-speed drives.

As an OEM module, it integrates seamlessly with ABB’s Control Builder M software, supporting drag-and-drop configuration of Modbus registers and communication parameters. Its dual-port design, isolation, and robust protection make it a reliable solution for legacy device integration in harsh industrial environments where downtime from communication failures is costly.