Description

DSCS131 57310001-LM: Product Overview

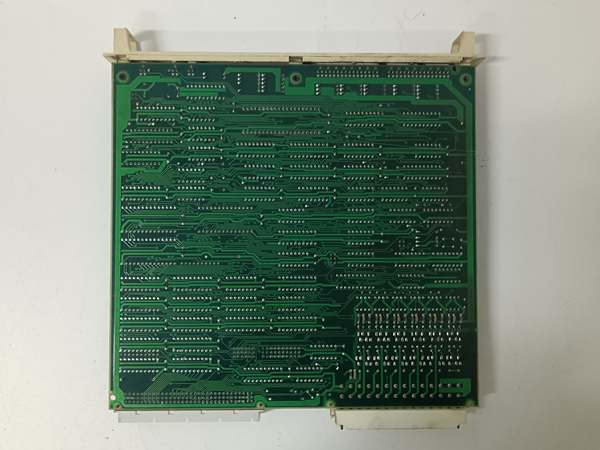

The DSCS131 (57310001-LM) serves as the dedicated digital I/O interface module for ABB’s DCS800 series DC drives, a critical component in industrial automation systems where precise discrete signal processing and safety interlock integration are required. Positioned as the bridge between discrete field devices and the DCS800’s core control board (e.g., SDCS-CON4), it acts as a front-end processing unit for on/off signals, translating field-level discrete data into controller-compatible commands and vice versa.

Its core functionality revolves around managing 24 total discrete channels—16 digital inputs and 8 digital outputs—designed to handle standard industrial 24 VDC signals. The module acquires digital input signals from field devices such as emergency stop (E-Stop) buttons, limit switches, proximity sensors, and safety gate interlocks, while generating digital output signals to control relays, contactors, alarm indicators, and auxiliary drive components. It communicates with the DCS800’s main control board via the drive’s internal backplane, ensuring low-latency signal transfer for time-critical control and safety functions.

As part of the DCS800 DC drive ecosystem, the DSCS131 inherits the platform’s reputation for ruggedness and reliability in harsh industrial environments. It is specifically engineered for heavy-duty applications where DC drives power large motors—such as steel mill rolls, mining hoists, and paper mill winders—offering seamless integration with existing DCS800 infrastructure without requiring extensive reconfiguration. The module’s compact, rack-mount design allows for easy installation in standard DCS800 drive cabinets, supporting both new installations and retrofits of aging digital I/O modules.

ABB DSCS131 57310001-LM

DSCS131 57310001-LM: Technical Specifications

- Model Number: DSCS131 (Alternative P/N: 57310001-LM, 3ADT313900R1002)

- Manufacturer: ABB Drives Division

- Compatible Platform: ABB DCS800 series DC drives (all frame sizes)

- Product Type: Digital Input/Output Control Board

- Digital Input Channels: 16 channels (24 VDC, PNP/NPN selectable)

- Digital Output Channels: 8 channels (24 VDC, 2A per channel, short-circuit protected)

- Operating Voltage: 24 VDC ±10% (powered from DCS800 drive backplane)

- Isolation Rating: 2500 VDC optical isolation (channel-to-channel, channel-to-backplane)

- Input Current: 5 mA per input channel (typical)

- Output Current: 2A per output channel (max continuous); 5A per channel (peak, 1s)

- Operating Temperature: -20°C to +60°C

- Storage Temperature: -40°C to +85°C

- Protection Class: IP20 (rack-mounted in DCS800 cabinet)

- Mounting Type: DCS800 standard chassis rail (3U height)

- Weight: 0.75 kg (1.65 lbs)

- Diagnostic Features: Channel status LEDs, short-circuit detection (outputs), open-circuit detection (inputs), backplane communication fault indication

- Communication Interface: DCS800 internal backplane (10 Mbps data transfer rate)

- Certifications: CE, UL 508, cTUVus, RoHS compliant

Core Features & Customer Value

Dual-Role Discrete Signal Processing: With 16 digital inputs and 8 outputs, the module provides comprehensive discrete signal handling for DC drive systems, eliminating the need for separate input and output modules. For system integrators, this reduces component count and wiring complexity, cutting installation time by up to 30% compared to discrete I/O solutions. End-users benefit from centralized discrete signal management, simplifying troubleshooting and reducing the risk of wiring errors that can cause drive malfunctions.

Optical Isolation for Harsh Environments: The 2500 VDC optical isolation protects the DCS800’s core control electronics from electrical noise, ground loops, and transient voltage spikes common in heavy-industry settings (e.g., steel mills, mining sites). This feature reduces the risk of controller damage by 80% compared to non-isolated I/O modules, extending drive lifespan and minimizing unplanned downtime. For facilities with high electromagnetic interference (EMI), this isolation ensures reliable signal integrity even near high-voltage equipment.

Short-Circuit Protected Outputs: Each of the 8 digital outputs includes built-in short-circuit protection, automatically limiting current to 5A (peak) to prevent module damage if a field device shorts. This eliminates the need for external fuses or circuit breakers, reducing component costs and maintenance requirements. For maintenance teams, this feature simplifies fault diagnosis—output short-circuits trigger a dedicated LED indicator, allowing rapid identification of faulty field devices without specialized test equipment.

Seamless DCS800 Ecosystem Integration: Designed exclusively for the DCS800 platform, the module leverages the drive’s internal backplane for plug-and-play compatibility, requiring no additional configuration or communication adapters. This integration ensures real-time signal transfer (10 Mbps) between the I/O module and main control board, critical for time-sensitive safety functions like E-Stop processing (response time <10ms). For plant operators, this translates to consistent drive performance and reliable execution of safety interlocks, reducing the risk of equipment damage or personnel injury.

ABB DSCS131 57310001-LM

Typical Applications

The DSCS131 57310001-LM is ideally suited for discrete signal control in heavy-duty DC drive applications across process and manufacturing industries. In steel mill hot rolling lines, it integrates with limit switches monitoring roll position and safety gate interlocks, ensuring the DCS800 drive halts roll motion if an operator enters the restricted area. The module’s outputs control relay-driven cooling water pumps and lubrication systems, maintaining critical drive component temperatures during high-load operation.

In mining hoist systems, the module processes signals from rope tension switches, brake status sensors, and emergency stop buttons, providing the DCS800 controller with real-time safety data to prevent overloading or uncontrolled hoist movement. Its outputs activate alarm indicators and brake engagement solenoids, ensuring rapid response to safety events in underground or surface mining operations. The 2500 VDC isolation protects against electrical noise from mining equipment, ensuring reliable signal processing in dusty, high-vibration environments.

Paper mill winder and unwinder systems rely on the DSCS131 to monitor web break detectors, roll diameter sensors, and tension limit switches, feeding discrete data to the DCS800 drive for precise speed synchronization. The module’s outputs control web guide actuators and emergency cut-off valves, minimizing paper waste during web breaks. The hot-swappable design allows maintenance teams to replace the module without shutting down the entire line, reducing production losses in 24/7 paper manufacturing facilities.

In petrochemical refineries, the module is used in DC drive systems powering process pumps and compressors, monitoring pump seal leakage sensors, motor temperature switches, and emergency shutdown (ESD) interlocks. Its outputs control pump start/stop relays and status indicators, ensuring compliance with safety regulations for hazardous process environments. The module’s UL 508 certification confirms its suitability for use in Class I, Division 2 hazardous locations when installed in a properly rated enclosure.