Description

Key Technical Specifications

- Model Number: ABB DSCA114 57510001-AA

- Manufacturer: ABB

- Input Type: Universal (4-20mA current, 0-10V DC/±10V DC voltage, software-selectable)

- Number of Input Channels: 4 (individually isolated)

- Input Current Range: 4-20mA (2-wire/4-wire, loop-powered compatible)

- Input Voltage Range: 0-10V DC, ±10V DC (±10% tolerance)

- Measurement Accuracy: ±0.05% of full scale (current/voltage)

- Operating Temperature: -25°C to 70°C (-13°F to 158°F)

- Storage Temperature: -40°C to 85°C (-40°F to 185°F)

- Isolation: 1kV AC (channel-to-channel, channel-to-backplane, 1-minute withstand)

- Response Time: ≤10ms (90% step response)

- Power Supply: 24V DC ±10% (21.6V DC to 26.4V DC), from AC 800M backplane

- Power Consumption: 0.8W (standby), 1.5W (full load)

- Mounting: AC 800M I/O rack (compatible with PM850/PM860/PM861/PM865 CPUs)

- Connector Type: 2 x spring-cage terminal blocks (2 channels per block)

- Protection Features: Short-circuit protection (per channel), ESD protection (±15kV air)

- Compatibility: ABB AC 800M controllers (firmware ≥3.1)

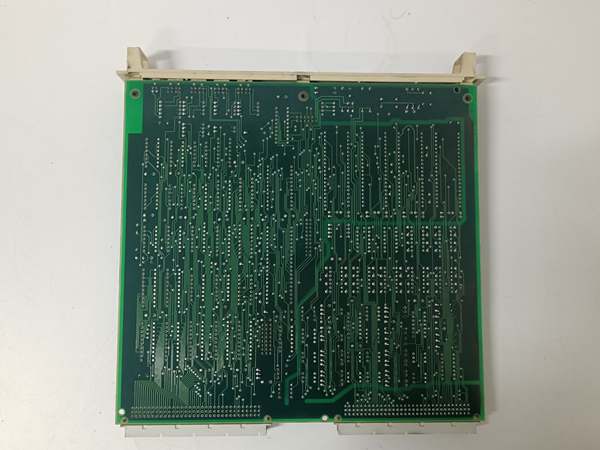

DSCA114 57510001-AA

Field Application & Problem Solved

In industrial process control—chemical reactors, pressure vessels, and flow systems—accurate measurement of continuous variables requires analog input modules that balance precision, flexibility, and noise immunity. The challenge? Many analog modules lock users into a single input type (current or voltage), requiring multiple modules for mixed-sensor setups. Low-precision modules introduce measurement errors that disrupt process stability, while non-isolated channels suffer from cross-talk in noisy industrial environments. Third-party modules often fail to sync with the AC 800M backplane, causing delayed data that compromises closed-loop control. The ABB DSCA114 solves these pain points with universal input compatibility, high precision, and robust channel isolation.

You’ll typically find this module in applications like monitoring reactor pressure with 4-20mA transmitters in chemical plants, measuring liquid level with 0-10V sensors in storage tanks, or tracking steam temperature via signal-conditioned voltage inputs in power plants. It’s a staple in precision process control (e.g., pharmaceutical batch processing), where its ±0.05% accuracy ensures product consistency. In water treatment facilities, it monitors flow rates and pH levels, relying on 1kV isolation to withstand noise from pump drives. It also excels in retrofits, upgrading older AC 800M systems to handle diverse analog sensors without rewiring or controller modifications.

Its core value is precision and flexibility for critical process sensing. The universal input eliminates the need for specialized modules, simplifying inventory and installation. Channel isolation blocks noise and prevents fault propagation, while high accuracy ensures reliable data for control logic. For operators, this means tighter process control, reduced waste, and minimized downtime—critical in industries where variable deviations lead to product defects or safety hazards.

Installation & Maintenance Pitfalls (Expert Tips)

- Input Range Mismatch (Software vs. Sensor): Rookies often configure a channel for 4-20mA but connect a 0-10V sensor, resulting in distorted or no readings. This is a common mistake in mixed-sensor setups. After wiring, use Control Builder M to confirm each channel’s input type (current/voltage) matches the sensor’s output. Test with a precision signal generator: simulate 4mA/20mA (current) or 0V/10V (voltage) to verify the module registers the full range.

- Loop Power Overlap for 2-Wire Transmitters: The module provides 24V DC loop power for 2-wire 4-20mA transmitters, but rookies often connect external power to these sensors. This creates a voltage conflict that damages the module’s loop power circuit or the transmitter. Check the sensor’s datasheet: 2-wire transmitters draw power from the module’s loop, while 4-wire transmitters require external power. Disable loop power in software for 4-wire sensors to avoid damage.

- Poor Wiring Practices (Noise = Fluctuating Readings): Analog signals are sensitive to electromagnetic interference (EMI), but rookies often run sensor wires parallel to high-voltage power cables or use unshielded wire. This induces noise, causing erratic readings (e.g., fluctuating pressure values). Use shielded twisted-pair (STP) cable for all analog wiring, route it at least 50cm away from power cables, and ground the shield at the module end only (single-point grounding).

- Calibration Neglect (Drift = Inaccurate Data): Over time, environmental factors (temperature, vibration) can cause calibration drift, but rookies often skip periodic calibration. This leads to gradual accuracy loss that compromises process control. Calibrate each channel annually using a NIST-traceable signal generator. Record calibration values in Control Builder M to offset drift, and verify readings against a handheld multimeter during routine maintenance.

DSCA114 57510001-AA

Technical Deep Dive & Overview

The ABB DSCA114 57510001-AA is a 4-channel universal analog input module engineered for precision process sensing in ABB’s AC 800M control systems. Its core design centers on high-precision analog-to-digital (A/D) conversion—24-bit resolution with ±0.05% full-scale accuracy—ensuring reliable measurement of low-level sensor signals. Each channel is individually isolated with 1kV AC rating, achieved via optocouplers and isolated power supplies that block EMI and prevent ground loops.

The module’s universal input circuitry supports both current (4-20mA) and voltage (0-10V/±10V) signals, with software-selectable ranges to match common industrial sensors (transmitters, transducers, signal conditioners). For 2-wire 4-20mA transmitters, the module provides regulated 24V DC loop power (max 25mA per channel), simplifying wiring. Built-in low-pass filters suppress high-frequency noise, with filter cutoff adjustable via software to match process speed.

Communication with the AC 800M CPU occurs via the rack’s high-speed backplane bus (100Mbps), enabling real-time data transfer. The module’s internal microcontroller caches converted digital values and updates the CPU at 10ms intervals, ensuring control logic responsiveness. Configuration settings (input range, loop power, filtering) are stored in non-volatile memory, retaining data during power loss or module replacement.

Built for industrial ruggedness, the DSCA114 withstands vibration (up to 5g at 10-2000Hz) and temperature extremes (-25°C to 70°C). The spring-cage terminal blocks simplify tool-less wiring, reducing installation time and human error. Its compact 1-slot design maximizes I/O density in AC 800M racks, while compliance with IEC 61131-2 ensures compatibility with global industrial standards.

As an OEM module, it integrates seamlessly with ABB’s Control Builder M software, supporting drag-and-drop I/O mapping and calibration. Its focus on precision, isolation, and flexibility makes it a critical component in analog sensing applications where accurate, reliable data is essential for process control and safety.