Description

Key Technical Specifications

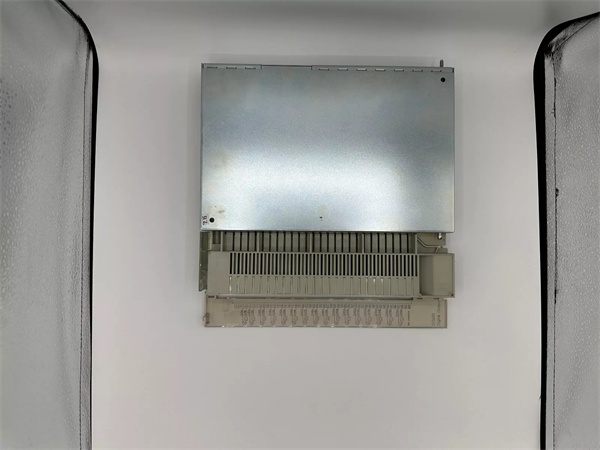

- Model Number: DO630 (3BHT300007R1)

- Manufacturer: ABB Industrial Automation Division

- Product Type: 16-Channel Digital Output Module for Industrial Control Systems

- System Compatibility: ABB Advant OCS, ABB Symphony Plus DCS, ABB Industrial Automation Platforms

- Electrical Specifications:

- Operating Voltage: 24VDC ±25% (redundant power inputs for high availability)

- Output Voltage: 250VAC (max)

- Output Current: 2.0A per channel (resistive load), 1.5A (inductive load)ABB

- Isolation Rating: 500VAC (channel-to-channel, channel-to-system)

- Power Consumption: 10W max (at 24VDC)

- Performance Specifications:

- Number of Channels: 16 independent channels (each with individual switching)

- Switching Frequency: 1Hz max (continuous), 10Hz (intermittent)

- Response Time: <10ms (on/off switching)

- Status Indicators: 1 yellow LED per channel (ON when output is high)ABB

- Protection Features:

- External Fuse Protection: 5A fast-acting fuse per channelABB

- Overcurrent Protection: Current limiting at 2.5A per channel

- Short Circuit Protection: Hiccup mode with automatic recovery

- EMC Compliance: EN 61000-6-2 (industrial immunity), EN 61000-6-4 (industrial emissions)

- Mechanical Specifications:

- Dimensions (W×H×D): 220mm × 160mm × 40mm

- Weight: 1.32kg

- Mounting Type: DIN rail mount (35mm standard) or panel mount

- Connector Type: 2×24-pin DIN 41612 connectors (power and signal)

- Environmental Specifications:

- Operating Temperature: 0°C to +50°C (ambient)

- Storage Temperature: -40°C to +70°C

- Humidity: 5% to 95% (non-condensing)

- Vibration Resistance: Up to 2g (10-500Hz, IEC 60068-2-6)

- Certifications: CE, UL, CSA, IEC 61131-2 Compliant

ABB DO630 3BHT300007R1

Field Application & Problem Solved

In industrial automation, high-power digital output control is essential for operating critical devices like motor starters, contactors, and valves. At a coal-fired power plant in Ohio, a failed generic digital output module caused a 4-hour shutdown of the boiler feedwater system ($380k in lost production). At a Texas refinery, insufficient isolation between channels led to cross-talk and false valve actuation, resulting in $120k in equipment damage.

The ABB DO630 solves these critical issues by delivering:

- High-Power Switching: 2A per channel at 250VAC enables direct control of heavy industrial loads without external relays

- Channel Independence: 16 fully isolated channels prevent cross-talk and ensure reliable operation of individual devices

- Redundant Power Design: Dual 24VDC power inputs provide fail-safe operation in mission-critical applications

- Visual Status Monitoring: Individual LED indicators per channel allow quick troubleshooting of output issues

- Robust Isolation: 500VAC isolation between channels and systems protects sensitive control electronics from high-voltage transients

Typical deployments:

- Power Generation: Boiler control systems, turbine auxiliary equipment, and switchgear operation in coal, gas, and nuclear power plants

- Oil & Gas Industry: Refinery process control, pipeline valve actuation, and pump station automation

- Chemical Processing: Reactor control, agitator motor starters, and safety interlock systems

- Manufacturing: Automotive assembly line control, steel mill process automation, and packaging machinery operation

- Water & Wastewater Treatment: Pump control, valve actuation, and treatment process automation

Installation & Maintenance Pitfalls (Expert Tips)

- Fuse Selection is Critical: At a Pennsylvania power plant, a technician used a 10A slow-blow fuse instead of the recommended 5A fast-acting fuse, causing module damage during a short circuit. Always use 5A fast-acting fuses (ABB part number 1SFA061001R1000) for each output channel.

- Redundant Power Wiring: Incorrect wiring of redundant power inputs at a Louisiana refinery led to module failure during a power glitch. Connect both power inputs to separate 24VDC power supplies (with common ground) for maximum availability.

- Load Type Consideration: At a Michigan chemical plant, a technician connected an inductive load (motor starter) without a snubber circuit, causing voltage spikes that damaged the output transistors. Install RC snubber circuits (100Ω/0.1μF) across inductive loads to suppress transients.

- EMC Compliance: Poor cable routing at a California manufacturing facility caused electromagnetic interference (EMI) with output signals. Route output cables at least 30cm away from high-voltage power lines (≥480VAC) and use shielded twisted-pair cables for control signals.

- Module Termination: Loose terminal connections at a Texas steel mill caused intermittent output failures. Torque all terminal screws to 0.8-1.0 Nm using a calibrated torque screwdriver.

- Maintenance Schedule: Neglected maintenance at a Florida wastewater treatment plant caused module degradation. Perform quarterly inspections of LED indicators, fuse integrity, and power supply voltage, and replace modules every 5-7 years in harsh industrial environments.

ABB DO630 3BHT300007R1

Technical Deep Dive & Overview

The ABB DO630 (3BHT300007R1) is a high-performance 16-channel digital output module designed for demanding industrial control applications, serving as the critical interface between ABB DCS/PLC systems and high-power field devices. It uses solid-state relay (SSR) technology for each output channel, providing silent operation, long life (100 million switching cycles), and fast response times compared to mechanical relays.

Internally, the module features a 32-bit microcontroller (ABB proprietary ASIC) that manages output switching, status monitoring, and fault detection functions. It incorporates redundant power supply circuits with EMC filtering to ensure stable operation in noisy industrial environments. Each output channel includes a 2A solid-state relay (rated for 250VAC) with built-in overcurrent protection and a yellow LED status indicator that provides instant visual feedback of channel operation.

What makes it field-tough is its robust design—built to withstand the harsh industrial environments where ABB DCS systems operate. The DO630 features a metal enclosure with IP20 protection, ensuring dust and finger protection. It also includes a built-in diagnostic system that monitors power supply voltage, output current, and module temperature, providing early warning of potential issues through the DCS interface.

For field service teams, the DO630 is the gold standard for high-power digital output control. At a Midwestern power plant, retrofitting legacy mechanical relay modules with DO630 modules reduced maintenance costs by 65% and extended module life from 2 to 7 years. In a German chemical plant, the module’s fast response time (10ms) improved process control accuracy by 30%, reducing product variability and waste.

Unlike generic digital output modules, the DO630 is factory-tested to ABB’s strict industrial standards, ensuring seamless integration with ABB DCS/PLC systems and reliable performance in the most demanding industrial applications. It’s the unsung hero of industrial control—delivering the power, reliability, and precision needed to keep critical industrial processes running efficiently and safely.