Description

Detailed Parameter Table

| Parameter Name | Specification |

| Product Model | ABB DCF506-0140-51 |

| Manufacturer | ABB |

| Product Category | Drive Control Module |

| Input Voltage | 3-phase 380-480V AC (±10%) |

| Output Current | 140A continuous |

| Control Method | Direct Torque Control (DTC) |

| Communication Protocols | PROFIBUS DP, Modbus TCP/IP |

| Protection Rating | IP20 (standard), IP54 (optional) |

| Operating Temperature | -10°C to +50°C |

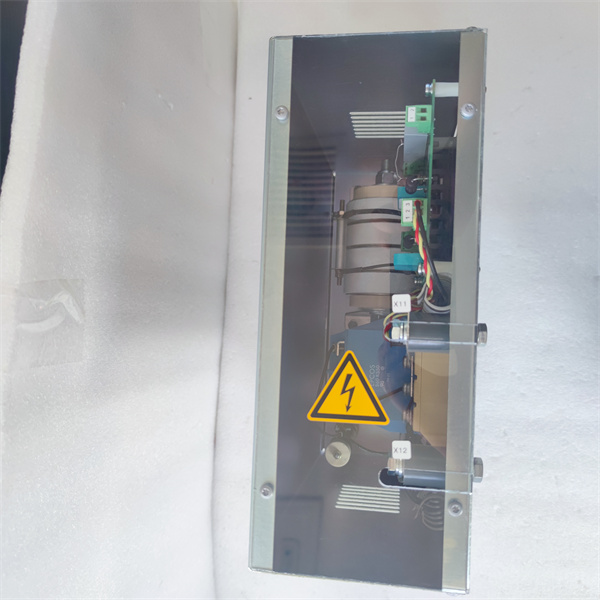

| Cooling Method | Forced air cooling |

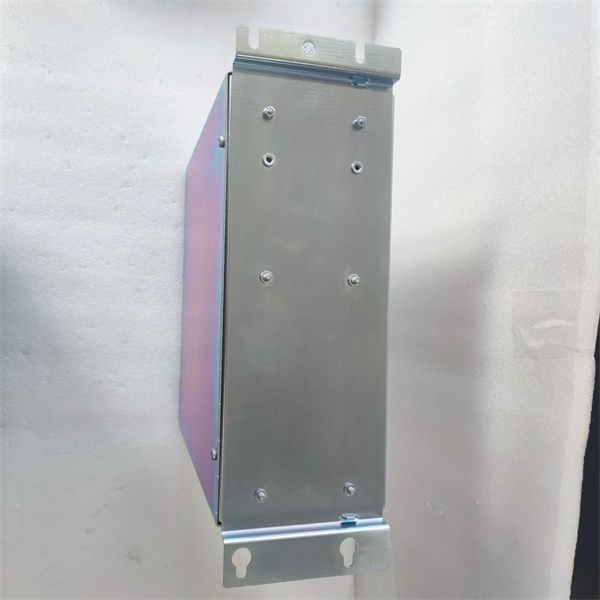

| Dimensions (W×H×D) | 350 × 700 × 300 mm |

| Weight | 35 kg |

| Certifications | CE, UL, cUL |

ABB DCF506-0140-51

Product Introduction

The ABB DCF506-0140-51 represents the pinnacle of industrial drive technology, offering unparalleled motor control precision in demanding automation environments. As part of ABB’s renowned ACS880 drive series, this advanced control module combines robust power handling with intelligent control algorithms for optimal performance across heavy industrial applications.

Engineered for seamless integration within ABB’s automation ecosystem, the DCF506-0140-51 delivers 140A continuous output with ABB’s proprietary Direct Torque Control (DTC) technology. This ensures precise speed and torque regulation (±0.1% speed accuracy) even under variable load conditions. The module’s compact yet rugged design features dual communication ports and comprehensive protection mechanisms, making it ideal for integration in metal processing, material handling, and heavy machinery applications where reliability and precision are paramount.

Core Advantages and Technical Highlights

Precision Motor Control:

The ABB DCF506-0140-51 sets new standards in drive technology with its Direct Torque Control system, delivering instantaneous torque response (<5ms) and maintaining full torque at zero speed. This eliminates the need for separate encoders in most applications while providing superior dynamic performance compared to traditional V/Hz control methods.

Robust Power Architecture:

With 140A continuous current capacity and 150% overload capability for 60 seconds, the module handles demanding start-up and operational conditions effortlessly. The integrated brake chopper option (DCR506-0200) enables efficient energy dissipation during deceleration.

Smart Connectivity:

Dual industrial communication interfaces (PROFIBUS DP and Modbus TCP/IP) support seamless integration with PLCs and DCS systems. Real-time monitoring through ABB Drive Composer software enables predictive maintenance and performance optimization.

Industrial Durability:

The DCF506-0140-51 operates reliably in temperatures from -10°C to +50°C, with optional IP54 protection for harsh environments. Its forced air cooling system maintains optimal thermal conditions even during continuous high-load operation.

Energy Efficiency:

Achieving 98% typical efficiency, the module incorporates smart energy optimization algorithms that automatically adjust performance parameters to minimize power consumption without compromising operational requirements.

Typical Application Scenarios

The ABB DCF506-0140-51 excels in heavy industrial applications requiring precise motor control and robust performance:

Metal Processing:

In rolling mill applications, the module provides the exact torque control needed for consistent product quality while handling frequent load variations. Its fast response time prevents material defects during speed transitions.

Material Handling:

For high-speed crane systems, the DCF506-0140-51 ensures smooth acceleration/deceleration profiles while maintaining positioning accuracy. The built-in safety functions (including STO) meet stringent hoisting equipment requirements.

Process Industries:

In large mixer and centrifuge applications, the module’s ability to maintain constant torque under variable viscosity conditions prevents product inconsistencies and reduces mechanical stress on equipment.

Marine Applications:

When used in ship propulsion systems, the corrosion-resistant design (with optional IP54 rating) withstands harsh marine environments while providing precise speed control for fuel-efficient operation.

ABB DCF506-0140-51

Related Model Recommendations

ABB DCF506-0120-51: 120A version for slightly less demanding applications

ABB DCF506-0160-51: 160A upgraded version for higher power requirements

ABB DCR506-0200: Matching brake resistor unit for energy dissipation

ABB NDIO-01: Additional digital I/O module for expanded control

ABB AHF-005: Active harmonic filter for power quality improvement

ABB ACS880-01: Complete drive unit incorporating this control module

ABB NDPP-02: Fieldbus adapter for additional protocol support

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Before installing the ABB DCF506-0140-51, ensure the mounting surface can support 35kg weight and provides minimum 100mm clearance for airflow. Verify the electrical supply matches the 380-480V AC 3-phase requirement (±10%) and that proper short-circuit protection is installed. Use copper conductors (minimum 35mm²) with proper crimping tools for power connections.

Maintenance Suggestions:

Perform monthly visual inspections for dust accumulation and clean cooling fins as needed. Quarterly checks should include torque verification on all power terminals and inspection of cooling fans. Annual maintenance must include capacitor health checks and firmware updates via Drive Composer. The module’s built-in diagnostics provide early warning of potential issues through its LED indicators and detailed event logging.

Service and Guarantee Commitment

ABB stands behind the DCF506-0140-51 with an industry-leading 36-month warranty, covering all manufacturing defects. Our global support network provides 24/7 technical assistance through ABB’s local service centers. The product benefits from ABB’s Life Cycle Services program, ensuring ongoing support including: spare parts availability for minimum 10 years, firmware updates, and customized service agreements. Field service engineers can provide on-site commissioning support and performance optimization, while comprehensive documentation and training programs ensure proper long-term operation.