Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | CMA135 |

| Manufacturer | ABB |

| Product Category | HART Communication Module |

| Series | S800 I/O |

| HART Channels | 16 channels (multiplexed) |

| HART Protocol | HART 5/6/7 (supports all revisions) |

| Isolation | 1500 V AC (Channel-to-Channel & Channel-to-System) |

| Communication Interface | ABB internal S800 bus (to controller) |

| Field Interface | 2 x M12 circular connectors (8 HART pairs each) |

| Power Supply | Via S800 I/O baseplate (24 VDC nominal) |

| Power Consumption | Approx. 2.5 W (typical) |

| Operating Temperature | -25°C to +70°C (-13°F to +158°F) |

| Relative Humidity | 5% to 95% (non-condensing) |

| Certifications | CE, UL, cULus, ATEX (Zone 2), IECEx (Zone 2), DNV, DNV GL |

ABB CMA135

Product Introduction

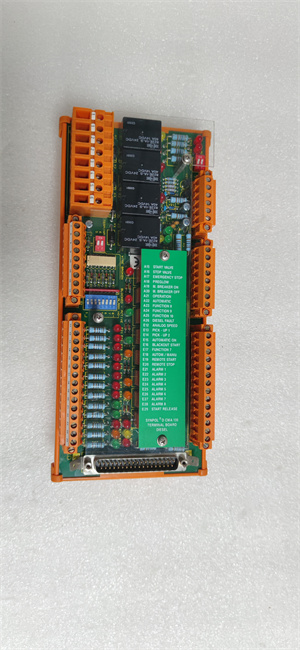

The ABB CMA135 is a specialized high-density HART communication module, a critical component within ABB’s globally deployed S800 I/O family. Designed explicitly for integration with ABB’s AC 800M and AC 800PEC controllers (like the PM864AK01 or PM861), the CMA135 serves as a powerful gateway for accessing rich diagnostic and secondary process variable (PV) data from HART-enabled field instruments. Its core function is HART signal multiplexing – efficiently extracting digital HART communication signals superimposed on the 4-20 mA analog current loops managed by standard S800 analog input/output modules (such as AI835, AO845).

As part of the robust and modular S800 I/O platform, the ABB CMA135 occupies a unique technical position. It eliminates the need for complex external HART multiplexers and dedicated wiring, significantly reducing installation cost and complexity. By seamlessly interfacing with the controller via the high-speed internal S800 bus, the CMA135 enables centralized access to valuable instrument data – device status, calibration information, diagnostics, and multiple process variables – directly within the control system’s engineering and asset management tools. This provides immense value in predictive maintenance, process optimization, and ensuring overall plant asset health.

Core Advantages and Technical Highlights

The ABB CMA135 delivers significant operational and economic benefits through its specialized design:

High-Density HART Multiplexing: The CMA135 efficiently handles HART communication for up to 16 field instruments simultaneously through just two rugged M12 connectors. This high channel density drastically reduces cabinet space requirements, wiring complexity, and overall project costs compared to traditional point-to-point HART solutions or lower-density multiplexers.

Seamless S800 I/O Integration: Designed as a native module within the S800 I/O architecture, the CMA135 plugs directly into the S800 baseplate (e.g., SA811). It communicates transparently with the controlling processor (like PM864AK01) over the internal high-speed bus, requiring no additional communication cards or complex gateways. Configuration and data access are fully integrated within ABB’s Control Builder M engineering environment.

Robust Isolation and Reliability: Engineered for harsh industrial environments, the CMA135 features 1500V AC isolation between channels and between the channels and the system bus. This protects sensitive control system electronics from ground loops and transient surges originating in the field. Its wide operating temperature range (-25°C to +70°C) and hazardous area certifications (ATEX/IECEx Zone 2) ensure reliable operation in demanding locations.

Simplified Asset Management: By bringing HART instrument data directly into the control system, the CMA135 enables real-time monitoring of device health, status, and diagnostics. This facilitates predictive maintenance strategies, reduces unnecessary field trips for manual checks, allows remote configuration changes, and helps maximize instrument uptime and lifespan. Access to secondary process variables (like sensor temperature or calculated flow) can also enhance process visibility and control without additional hardware.

Cost-Effective Scalability: Adding HART communication capability is modular and scalable with the CMA135. Users can deploy modules as needed alongside standard S800 I/O modules, providing a future-proof and economical path to implementing comprehensive HART device management across the plant.

Typical Application Scenarios

The ABB CMA135 is indispensable in industries where maximizing data from intelligent field instruments is crucial for efficiency and reliability:

Process Industries (Oil & Gas, Chemical, Petrochemical): In refineries and chemical plants, the CMA135 provides centralized access to HART data from thousands of transmitters (pressure, temperature, flow, level) and valve positioners. This enables real-time monitoring for leaks (pressure diagnostics), plugging (dp flow diagnostics), corrosion (corrosion monitor diagnostics), and valve health/stiction, driving predictive maintenance and reducing unplanned downtime.

Pharmaceutical and Fine Chemicals: Where batch recipe adherence and validation (e.g., FDA 21 CFR Part 11) are critical, the CMA135 allows remote verification of instrument calibration status and configuration directly within the control system database, streamlining audits and ensuring data integrity.

Water and Wastewater Treatment: Monitoring pump health via vibration diagnostics on HART pressure transmitters, verifying level sensor functionality, and accessing multi-variable flow meter data (mass flow, density, temperature) becomes centralized and efficient using the CMA135, optimizing resource management and plant performance.

Power Generation: Accessing detailed diagnostics from critical HART instruments on boilers, turbines, and emissions control systems via the CMA135 supports condition-based maintenance, improving plant availability and safety.

Continuous Manufacturing (Pulp & Paper, Food & Beverage): Monitoring critical control valves for stiction or wear and accessing secondary variables from multi-parameter sensors enhances process control quality and reduces maintenance interventions, facilitated by the CMA135.

ABB CMA135

Related Model Recommendations

AI835: S800 HART-capable Analog Input module (16 channels). The CMA135 extracts HART data from instruments connected to modules like the AI835.

AO845: S800 HART-capable Analog Output module (8 channels). Used to control HART positioners; the CMA135 accesses their HART data.

SA811: S800 I/O baseplate module. The CMA135 requires a baseplate like the SA811 for mounting and power/communication.

SD822: S800 I/O Communication Module (for Profibus DP). Often used in the same rack as the CMA135 to connect the S800 I/O cluster to a Profibus network.

CI854A: Communication Interface Module (Profibus DP Master) for AC 800M controllers. Provides the Profibus link that an SD822 (and thus the CMA135‘s data path) might connect to.

PM861: AC 800M Performance controller (step below PM864AK01). A common controller platform managing S800 I/O including the CMA135.

PM864AK01: AC 800M High Performance controller. The high-end processor frequently managing complex systems utilizing CMA135 modules.

TU847: Touch Panel Operator Terminal. Provides local HMI access to data and diagnostics from instruments monitored by the CMA135.

CombiMaster M12 (e.g., TA-M12W…): ABB’s range of M12 field connector blocks, used to wire field instruments to the CMA135‘s M12 sockets.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the ABB CMA135, ensure the S800 baseplate (e.g., SA811) is correctly mounted and powered within the cabinet. Verify the ambient conditions meet the specified temperature and humidity range. Use appropriate ESD protection. Have the necessary M12 field connectors (e.g., ABB CombiMaster) and pre-assembled cables ready for connection to the HART instruments. Ensure the controlling processor (e.g., PM864AK01) and Control Builder M engineering station are operational and the relevant project hardware configuration includes the CMA135 module.

Maintenance Suggestions: The CMA135 module requires minimal physical maintenance. Regularly inspect the M12 connectors for tightness and signs of damage or corrosion. Monitor the module status LED indicators (visible on the front edge) during operation. Utilize the comprehensive diagnostic information available through Control Builder M and the connected controller (e.g., PM864AK01) to monitor HART communication status per channel and device health. Keep the firmware of the CMA135 updated according to ABB service bulletins to ensure compatibility and access to the latest features. Ensure the HART device configuration (DD files) in the engineering system is up-to-date.

Service and Guarantee Commitment

ABB provides a standard warranty for the CMA135, typically 18 months from shipment, covering defects in materials and workmanship under normal operating conditions as defined in the product manual and ABB’s general terms of sale. ABB’s global service network offers extensive technical support for the CMA135, including installation guidance, configuration assistance, troubleshooting, and access to firmware updates through official channels. Comprehensive documentation, including detailed hardware manuals, application notes, and configuration guides, is readily available. For critical operations, ABB offers tailored service agreements encompassing extended warranty coverage, priority support, on-site engineering assistance, and rapid replacement services to ensure the continuous operation and long-term performance of systems utilizing the CMA135. ABB is committed to the long-term support and availability of spare parts for the S800 I/O platform.