Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

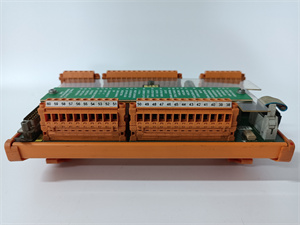

| Product Model | ABB CMA132 3DDE300412 |

| Manufacturer | ABB |

| Product Category | Field-mounted Process Controller |

| Control Functions | PID, ratio, cascade, feedforward |

| Input Channels | 4 universal analog inputs (TC/RTD/mA/V) |

| Output Channels | 2 analog outputs, 4 digital outputs |

| Communication Protocols | Modbus RTU, HART, PROFIBUS DP (optional) |

| Processor | 32-bit RISC with floating-point math |

| Memory | 2MB flash, 512KB RAM |

| Power Supply | 24V DC (±10%) or 100-240V AC |

| Operating Temperature | -40°C to +70°C |

| Enclosure Rating | IP66/NEMA 4X |

| Dimensions | 150mm × 110mm × 65mm |

| Mounting | Field or panel mount |

ABB CMA132 3DDE300412

Product Introduction

The ABB CMA132 3DDE300412 is a rugged field-mounted process controller designed for demanding industrial applications. Part of ABB’s ControlMaster series, this advanced controller combines sophisticated control algorithms with robust field construction, making it ideal for deployment in harsh environments.

Featuring four universal analog inputs that accept thermocouples, RTDs, and standard current/voltage signals, the CMA132 provides exceptional flexibility for process measurement applications. Its powerful 32-bit processor executes complex control strategies including PID with auto-tuning, cascade, and feedforward control with millisecond response times.

The controller’s IP66/NEMA 4X rated enclosure allows direct field installation, eliminating the need for additional protection cabinets in most industrial environments. With optional PROFIBUS DP communication, the ABB CMA132 3DDE300412 seamlessly integrates into modern automation architectures.

Core Advantages and Technical Highlights

Extreme Environment Operation:

The CMA132 operates reliably in temperature extremes from -40°C to +70°C and withstands vibration, humidity, and corrosive atmospheres common in process industries.

Advanced Control Capabilities:

Beyond standard PID, the controller offers adaptive gain, fuzzy logic, and model-based control algorithms for challenging processes with non-linear characteristics or long dead times.

Universal Input Configuration:

Each of the four analog inputs can be independently configured for thermocouple (J,K,T,E,R,S,B,N), RTD (Pt100, Pt1000, Ni100, Cu10), or standard current/voltage signals (0-20mA, 4-20mA, 0-10V).

Dual Communication Ports:

Standard Modbus RTU (RS485) and HART communication, with optional PROFIBUS DP module availability for integration with DCS and PLC systems.

Intuitive Local Interface:

High-contrast LCD display with backlight and membrane keypad allows for local configuration and monitoring without requiring external tools.

Redundant Power Options:

The controller accepts both 24V DC and 100-240V AC power inputs, with optional battery backup for critical applications.

CMA132 3DDE300412

Typical Application Scenarios

The ABB CMA132 3DDE300412 excels in:

Oil & Gas Production:

Wellhead pressure control

Separator level management

Compressor anti-surge protection

Chemical Processing:

Reactor temperature cascade control

pH neutralization systems

Batch process sequencing

Water/Wastewater:

Pump station control

Chlorination dosing

Dissolved oxygen regulation

Power Generation:

Deaerator level control

Cooling water temperature regulation

Fuel gas pressure management

Food & Beverage:

Pasteurization temperature control

Mixing ratio control

CIP sequence management

Related Model Recommendations

ABB CMA121: Basic version with 2 analog inputs

ABB CMA141: Expanded I/O version with 8 analog inputs

ABB CMA150: Panel-mounted version with larger display

ABB CM10: Compact single-loop controller

ABB CM20: Dual-loop controller

ABB CM30: Multi-loop controller with advanced math

ABB CM40: Safety-rated controller for SIL2 applications

ABB CM50: High-density controller for OEM applications

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Select mounting location considering environmental conditions and maintenance access. Ensure proper cable entry using suitable cable glands for the enclosure rating. Verify power source matches controller requirements.

Commissioning:

Use the built-in configuration wizard to set up input types and control strategies. Perform sensor calibration using the controller’s calibration routines. Test all outputs and verify proper response to process changes before putting into service.

Maintenance Suggestions:

Regularly inspect enclosure seals for integrity. Check terminal tightness during scheduled maintenance. Monitor controller diagnostics for early detection of potential issues. Backup configuration settings after any changes.

Service and Guarantee Commitment

ABB provides a 36-month warranty for the CMA132 3DDE300412 controller. Our global service network offers 24/7 technical support for installation, configuration, and troubleshooting. Software updates and configuration tools are available through ABB’s online support portal.

For critical applications, ABB offers extended warranty options and priority replacement services. The controller undergoes extensive environmental and performance testing to ensure reliable operation in the most demanding industrial conditions. Factory recalibration and repair services are available throughout the product lifecycle.