Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

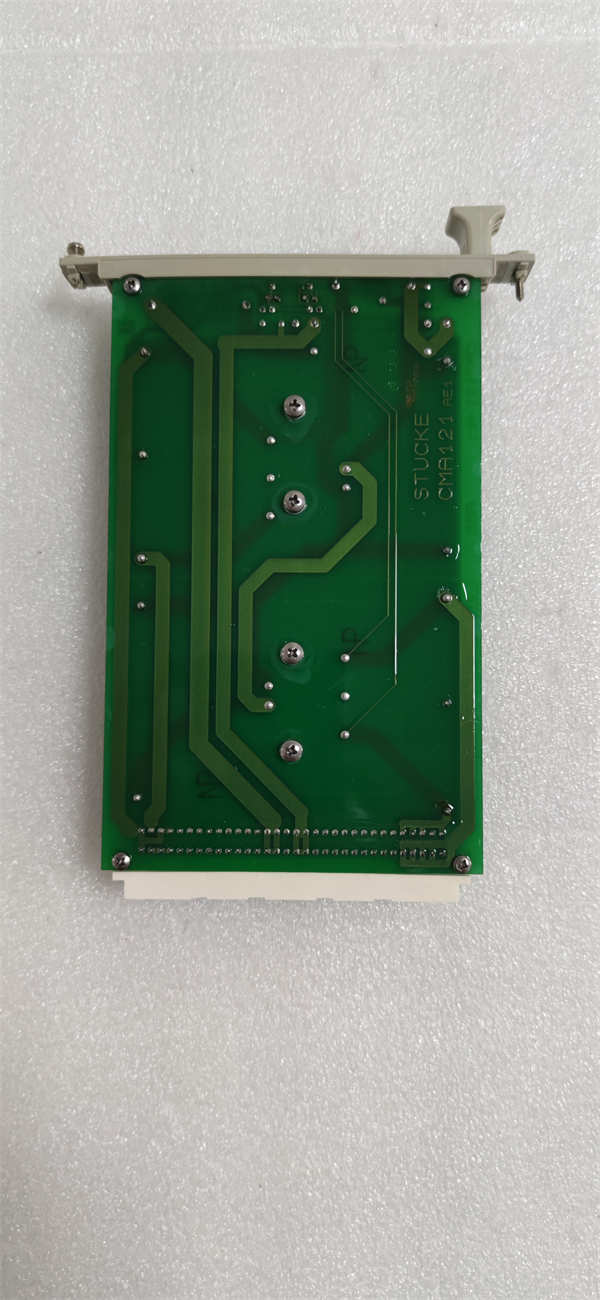

| Product Model | ABB CMA121 |

| Manufacturer | ABB |

| Product Category | PROFIBUS DP-V1 Slave Communication Adapter |

| Host Interface | S800 I/O Bus (via compatible base unit) |

| PROFIBUS Protocol | EN 50170 compliant DP-V1 |

| Data Transfer Rate | 9.6 kbps to 12 Mbps (Auto-negotiating) |

| Addressing Range | 1-125 (Software Configurable) |

| I/O Data Capacity | 244 Bytes Input / 244 Bytes Output |

| Galvanic Isolation | 500V AC (PROFIBUS to S800 bus) |

| Status Indicators | RUN, ERROR, BUS ACTIVE, DP SLAVE |

| Power Supply | 24 VDC ±10% (via S800 backplane) |

| Operating Temperature | -25°C to +70°C |

| Certifications | CE, UL, cULus, DNV-GL |

| Compatible Bases | ABB TB801, TB811, TB821 |

| Configuration | DIP switches + GSD file (2ABB61004438) |

ABB CMA121

Product Introduction

The ABB CMA121 is a high-performance communication adapter module designed to seamlessly integrate ABB’s S800 I/O systems into PROFIBUS DP-V1 networks. As a critical interface component within ABB’s industrial automation ecosystem, this adapter enables bidirectional data exchange between field devices and master control systems (PLCs/DCS). The ABB CMA121 transforms S800 I/O stations into intelligent PROFIBUS slaves, supporting both cyclic process data transfer and acyclic services for parameterization and diagnostics.

Engineered for reliability in demanding industrial environments, the ABB CMA121 operates as the communication backbone for distributed I/O architectures. It supports the full DP-V1 protocol specification, including alarm handling and extended diagnostics. When installed in compatible S800 base units like the ABB TB821, the module provides plug-and-play connectivity to major automation systems from Siemens, ABB, and other PROFIBUS-compatible platforms. Its compact design minimizes cabinet space while delivering robust performance in continuous process applications.

Core Advantages and Technical Highlights

Plug-and-Play Integration:

Automatic baud rate detection (9.6kbps-12Mbps)

Pre-certified GSD file for simple master configuration

Automatic I/O mapping to S800 modules

Extended Diagnostics Capability:

Detailed PROFIBUS status reporting (master/slave health)

S800 I/O channel-level error propagation to DP master

Watchdog monitoring for bus communication failures

High-Speed Performance:

1ms I/O update cycle at 12Mbps

<100µs process data latency

Dual-port memory architecture for concurrent processing

Robust Connectivity:

9-pin D-Sub connector with screw locking

Integrated bus termination (switch-selectable)

Surge protection (4kV) on PROFIBUS lines

Maintenance Optimization:

Hot-swappable in redundant controller configurations

Front-accessible DIP switches for node addressing

LED status indicators for rapid troubleshooting

Typical Application Scenarios

Automotive Manufacturing: The ABB CMA121 connects robotic cell sensors (S800 AI modules) to Siemens PLCs via PROFIBUS, enabling real-time quality monitoring in paint shops with 1ms response times.

Pharmaceutical Batch Plants: Integrates ABB S800 temperature modules (DSTA series) with Rockwell ControlLogix via PROFIBUS, ensuring GMP-compliant data logging for reactor vessels.

Marine Power Management: On LNG carriers, interfaces ABB S800 DI modules with propulsion control systems, providing DNV-GL certified alarm reporting to the bridge.

Packaging Machinery: Synchronizes servo drives via PROFIBUS with <100µs jitter, using ABB CMA121 to process encoder inputs from S800 counter modules.

Water Treatment SCADA: Links legacy ABB Advant controllers to modern DCS through PROFIBUS DP-V1, extending system lifecycle while enabling cloud data integration.

Related Model Recommendations

ABB TB821: Hot-swappable base unit for CMA121 mounting

ABB CMA142: PROFINET IO-Device adapter (alternative to PROFIBUS)

ABB CI871: Ethernet/IP communication interface

ABB SPHSS01: Signal conditioner for analog sensors

ABB SAIO22: Digital input module for direct field connections

ABB SCM81: HART multiplexer for smart instrument integration

ABB SD822: Redundant power supply for critical nodes

ABB CI854A: PROFIBUS Master module for controller integration

ABB CMA121

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Verify compatible base unit (TB801/TB811/TB821)

Set PROFIBUS address via DIP switches (OFF=1, ON=0)

Install terminating resistor (switch ON at bus endpoints)

Ground cable shield at both ends (<1Ω impedance)

Commissioning Procedure:

Load GSD file (2ABB61004438) into master configuration tool

Map S800 I/O channels to PROFIBUS process image

Verify data exchange with “Force & Monitor” function

Test bus failure response (watchdog timeout setting)

Maintenance Protocol:

Monthly: Inspect D-Sub connector integrity

Quarterly: Verify ground connections, clean ventilation slots

Annually: Update GSD file to latest revision

PROFIBUS Diagnostics: Use dedicated scanner (e.g., ABB PFT-101)

Module Replacement: Power down base unit before hot-swap modules

Service and Guarantee Commitment

ABB provides a 36-month warranty for the ABB CMA121, featuring:

Lifetime Support: 15-year spare parts availability

24/7 Technical Assistance: PROFIBUS specialists on-call

GSD File Management: Automatic version notifications

Repair Services: Flat-rate repair with 10-day global turnaround

Compatibility Guarantee: Certified interoperability with 50+ PLC platforms

All modules undergo 168-hour burn-in testing at 70°C and 95% humidity. Cybersecurity validation includes protocol fuzz testing per IEC 62443-3-3 standards. ABB’s PROFIBUS Competence Center offers free configuration audits for systems with >20 nodes.