Description

Key Technical Specifications

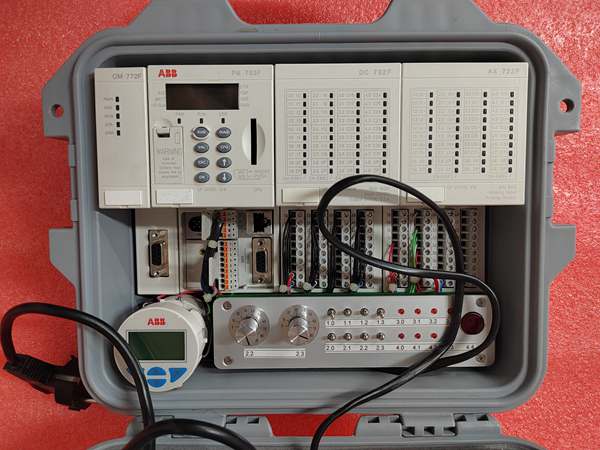

- Model Number: ABB CM772F

- Manufacturer: ABB

- Control Function: PID (Proportional-Integral-Derivative) control, on/off control (software-selectable)

- Input Type: Universal (RTD: Pt100/Pt1000; Thermocouple: K/J/T/E; 4-20mA; 0-10V DC)

- Input Channels: 2 universal analog inputs

- Output Channels: 2 relay outputs (8A @ 250V AC), 1 analog output (4-20mA/0-10V DC)

- Operating Temperature: 0°C to 55°C (32°F to 131°F)

- Storage Temperature: -20°C to 70°C (-4°F to 158°F)

- Isolation: 250V AC (input-to-output, input-to-power, 1-minute withstand)

- Power Supply: 24V DC ±10% / 100-240V AC ±10% (dual-range, auto-select)

- Power Consumption: Max 10VA (AC), Max 8W (DC)

- Mounting: DIN rail (35mm, EN 50022)

- Display: 2-line LCD with backlight, 4 pushbuttons for local configuration

- Protection Features: ESD protection (±8kV contact), short-circuit protection (outputs)

- Communication: Optional Modbus RTU (RS-485) via expansion port

- Accuracy: ±0.1% of full scale (analog inputs), ±0.2°C (RTD/thermocouple)

ABB CM772F

Field Application & Problem Solved

In industrial and building automation—HVAC systems, small process skids, and standalone equipment—precision control of temperature, pressure, or flow requires compact, self-contained modules that avoid complex PLC programming. The challenge? Many basic controllers lack universal input compatibility, forcing users to match specific sensors to the module. Standalone PID controllers often lack integrated I/O, requiring additional modules for sensor monitoring or actuator control. Low-cost options suffer from poor accuracy, leading to process drift, while complex PLC-based control is overkill for small-scale applications. The ABB CM772F solves these pain points with built-in PID control, universal inputs, integrated outputs, and local configuration—all in a compact DIN rail package.

You’ll typically find this module in applications like regulating chiller temperatures in data centers, controlling pressure in small compressed air systems, or maintaining liquid levels in storage tanks. It’s a staple in HVAC systems, where it controls air handler temperatures or boiler pressure via mixed sensors (RTDs for temperature, 4-20mA for pressure). In food processing, it regulates oven temperatures with K-type thermocouples, using its relay outputs to switch heating elements. It also excels in standalone equipment (e.g., laboratory reactors, test benches), where its local LCD and pushbuttons eliminate the need for external programming tools.

Its core value is simplicity and precision for small-scale control. The all-in-one design combines sensing, control, and actuation in a single module, reducing wiring and installation time. Universal inputs and configurable outputs adapt to diverse sensors and actuators, while built-in PID control ensures stable process regulation. For operators, this means easy setup, reliable performance, and cost savings—critical in applications where complex control systems are impractical or too expensive.

Installation & Maintenance Pitfalls (Expert Tips)

- Input Type Misconfiguration (Sensor vs. Module Setting): Rookies often connect a Pt100 RTD but leave the module set to 4-20mA, resulting in no readings or erratic values. This is a common mistake with universal inputs. Use the local LCD or software to match the input setting to the sensor type (RTD/thermocouple/analog). Test with a known signal: for RTD, apply a reference resistance; for 4-20mA, simulate 4mA (0%) and 20mA (100%) to confirm the module registers correctly.

- Relay Output Overloading (Exceeding 8A Limit): The module’s relay outputs are rated for 8A @ 250V AC, but rookies often connect high-current loads (e.g., 10A heaters) directly. This welds relay contacts or triggers short-circuit protection. Use external contactors for loads exceeding 8A, and never daisy-chain multiple high-power devices on a single relay. Check load current with a multimeter before commissioning.

- PID Tuning Neglect (Default Settings = Process Instability): Rookies often use default PID gains, leading to overshoot (e.g., temperature spiking above setpoint) or slow response (e.g., taking minutes to reach setpoint). Tune the PID parameters (proportional gain, integral time, derivative time) to match the process: increase proportional gain for faster response, integral time to eliminate steady-state error, and derivative time to dampen overshoot. Use the module’s auto-tune feature (if available) for initial setup, then fine-tune manually.

- Power Supply Mismatch (AC vs. DC): The module supports dual-range power (AC/DC), but rookies often connect 24V DC to the AC terminals (or vice versa), causing permanent damage. Check the module’s power input terminals: AC power connects to L/N, DC to +/-. Verify the power source voltage matches the module’s rating (100-240V AC or 21.6-26.4V DC) before applying power.

ABB CM772F

Technical Deep Dive & Overview

The ABB CM772F is a compact, self-contained process control module designed for small-scale automation applications. Its core design centers on a microcontroller that integrates PID control logic, universal input processing, and output driving—eliminating the need for separate components. The universal input circuitry accepts RTDs, thermocouples, current, and voltage signals, converting them to digital values via a 16-bit ADC for high accuracy.

Built-in PID control logic regulates the process variable (e.g., temperature) by adjusting the output (relay or analog) based on the difference between the setpoint and measured value. The module supports on/off control for simple applications and PID for precision regulation, with configurable parameters accessible via the local LCD or optional Modbus communication.

Dual relay outputs handle high-power loads (e.g., heaters, pumps), while the analog output provides proportional control for variable-speed drives or control valves. Short-circuit protection on outputs and ESD protection on inputs shield the module from wiring mistakes and environmental stress.

The dual-range power supply (AC/DC) and DIN rail mounting simplify installation in diverse environments. The LCD display and pushbuttons allow local configuration—setting setpoints, input types, and PID parameters—without external software. Optional Modbus RTU communication enables integration with SCADA systems for remote monitoring and control.

The module’s compact form factor (35mm DIN rail) saves panel space, while its robust construction withstands industrial and building automation environments. By combining sensing, control, and actuation in one unit, it delivers a cost-effective, easy-to-use solution for small-scale process regulation where complex PLCs are unnecessary.