Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

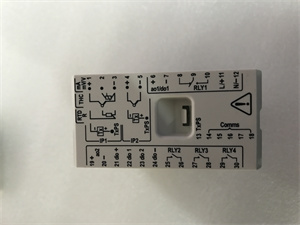

| Product Model | ABB CM10 |

| Manufacturer | ABB |

| Product Category | CANopen Master Communication Module |

| Compatible PLC Series | AC500 (PM5xx, PM5xx-S CPUs) |

| Supported Protocols | CANopen DS301 V4.02, CiA 302-3 |

| Data Transfer Rate | 10 kbps – 1 Mbps (configurable) |

| Electrical Interface | ISO 11898-2 (CAN High/Low) |

| Connection Type | 5-pin screw terminal (CAN_H, CAN_L, GND, +24V) |

| Maximum Nodes | 127 devices per network |

| SIL Certification | SIL 2 (IEC 61508) |

| Isolation Voltage | 500 V DC (field to logic) |

| Operating Temperature | -25°C to +70°C |

| Power Supply | 5 V DC via PLC backplane |

| Power Consumption | 1.8 W (typical) |

| Diagnostics | LED indicators (RUN, ERR, CAN) |

| Redundancy Support | 1:1 hot standby (with secondary module) |

| Dimensions (W×H×D) | 25×116×116 mm |

ABB CM10

Product Introduction

The ABB CM10 is a high-performance CANopen Master communication module engineered for ABB’s AC500 PLC platform, delivering deterministic fieldbus control for industrial automation systems. Designed to interface PM5xx and PM5xx-S CPUs with CANopen-enabled devices, the CM10 implements DS301 and CiA 302 standards for seamless integration of sensors, drives, and remote I/O. This module serves as a critical bridge between PLC logic and distributed field components, enabling real-time data exchange with precise synchronization capabilities.

As part of ABB’s modular communication portfolio, the CM10 supports both standard and safety-critical applications through its SIL 2 certification. Its technical architecture features hardware-level protocol processing that offloads communication tasks from the main CPU, ensuring consistent sub-millisecond cycle times even in complex networks. Within AC500-based control systems, the ABB CM10 reduces wiring complexity while providing deterministic control for motion applications, process sequencing, and safety interlocks.

Core Advantages and Technical Highlights

The ABB CM10 delivers exceptional operational value through advanced engineering:

Deterministic Performance: Hardware-accelerated protocol handling achieves ≤1ms cycle times for 64 PDOs. Integrated scheduler guarantees precise synchronization for distributed clocks (CiA 302-3).

Safety Integration: SIL 2 certification enables deployment in safety instrumented systems. Supports safety PDOs with CRC monitoring and configurable fail-safe behavior.

Robust Connectivity: Galvanic isolation (500V DC) eliminates ground loops. Built-in transient protection (IEC 61000-4-4/5) withstands industrial electrical noise.

Network Scalability: Manages up to 127 nodes across 1km distance. Automatic baud rate detection simplifies expansion.

Diagnostic Intelligence: Per-channel LED status (RUN/ERR/CAN) enables instant fault localization. Detailed error logging includes node-specific communication faults.

Redundancy Ready: Supports 1:1 hot standby configuration with automatic switchover (<50ms) for critical processes.

Engineering Efficiency: Pre-configured device profiles (EDS/DCF files) for rapid commissioning. Online node replacement without network reset.

Typical Application Scenarios

The ABB CM10 excels in distributed control architectures requiring deterministic communication:

Mobile Machinery: Controls hydraulic valves and sensors in construction equipment using CANopen’s vibration-resistant physical layer. SIL 2 compliance ensures safety interlocks for boom movement.

Packaging Lines: Synchronizes servo drives and encoders across high-speed wrappers with ≤100µs jitter for precise web handling.

Electric Vehicle Test Rigs: Interfaces with battery simulators and dynamometers using CiA 454 standard profiles for real-time parameter control.

Water Treatment Plants: Networks pump station controllers across large campuses with 1km cable runs between nodes.

Printing Presses: Coordinates tension control subsystems via CANopen’s SDO-PDO mapping for seamless job changeovers.

In each scenario, the CM10 reduces integration complexity while ensuring deterministic data exchange.

Related Model Recommendations

ABB CM12 – PROFIBUS DP Master module for AC500 integration.

ABB PM591 – High-performance CPU for complex CM10 networks.

ABB CI871 – EtherNet/IP Scanner for hybrid network architectures.

ABB SD821 – Remote I/O station compatible with CANopen.

ABB CP600 – HMI panel for visualizing CM10 network diagnostics.

ABB CM10

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Disconnect PLC power. Ground CAN shield at single point using 4mm² wire. Terminate bus ends with 120Ω resistors. Maintain ≥10cm separation from power cables. Secure CM10 to AC500 rack until latch engages.

Maintenance Suggestions: Monitor CAN LED for consistent blinking (indicates traffic). Verify termination resistance annually. Update device EDS files during planned downtime. Replace after 10 years service. For SIL 2 systems, validate safety PDO mapping biannually.

Service and Guarantee Commitment

ABB warrants the CM10 for 36 months against defects. Global support includes:

24/7 technical assistance via ABB support centers

Lifetime firmware updates with backward compatibility

SIL 2 documentation packages (FMEDA, validation reports)

Advance replacement program for critical failures

15-year minimum spare parts availability

On-site commissioning support

Free access to CANopen configuration tools

Extended service agreements include network health monitoring and predictive maintenance analytics.