Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

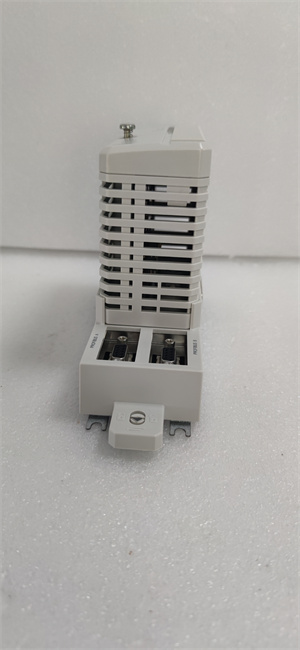

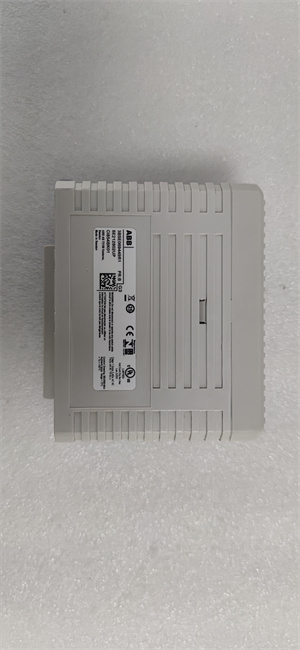

| Product Model | CI854BK01 |

| Manufacturer | ABB |

| Product Category | PROFIBUS Communication Interface Module |

| Interface Type | PROFIBUS-DP (RS-485) |

| Data Transfer Rate | 9.6 kbps – 12 Mbps (auto-negotiating) |

| Power Supply | 24 V DC (19.2–30 V DC), redundant inputs |

| Isolation | 500 V AC (between K-bus and PROFIBUS) |

| Operating Temperature | -25°C to +70°C |

| Relative Humidity | 5–95% (non-condensing) |

| Certifications | PROFIBUS DP-V1, CE, UL, ATEX Zone 2 |

| Connection Method | Screw terminals (field wiring) |

| Mounting | DIN rail (S800 I/O baseplate) |

| Dimensions (W×H×D) | 63 × 129 × 119 mm |

ABB CI854BK01

Product Introduction

The ABB CI854BK01 is a high-performance PROFIBUS-DP communication interface module designed for ABB’s S800 I/O system. It serves as a gateway between ABB’s control systems (e.g., AC800M PLCs) and PROFIBUS-DP networks, enabling seamless data exchange with sensors, drives, and remote I/O stations. As part of ABB’s industrial automation ecosystem, the ABB CI854BK01 supports PROFIBUS DP-V1 protocol standards, including cyclic process data exchange and acyclic diagnostics.

This module operates as a DP slave, integrating up to 244 bytes of input/output data per node into ABB’s K-bus architecture. Its ruggedized design ensures compatibility with ABB’s S800 series, allowing hot-swapping during operation to minimize downtime. The ABB CI854BK01 is engineered for mission-critical applications where deterministic communication and network resilience are paramount, providing a backbone for distributed control architectures in large-scale industrial installations.

Core Advantages and Technical Highlights

ABB CI854BK01 delivers unmatched reliability in industrial networking:

Robust Network Integration: Supports 12 Mbps PROFIBUS-DP with auto-baud detection and redundant 24V DC power inputs. Galvanic isolation (500V AC) between K-bus and field bus prevents ground loop interference, ensuring signal integrity in electrically noisy environments like steel mills or power plants.

High Availability Design: Hot-swappable module replacement allows maintenance without system shutdown. Built-in diagnostics monitor bus voltage, signal quality, and node status, triggering alerts in ABB’s Control Builder for preemptive fault resolution. The ABB CI854BK01 retains configuration during power loss, enabling instant restart.

Simplified Engineering: Pre-certified PROFIBUS GSD file (CI854BK01.gsd) enables plug-and-play integration with Siemens, Rockwell, and other DP masters. Configuration via Control Builder automates address assignment and I/O mapping, reducing commissioning time by 30% compared to generic gateways.

Extreme Environment Resilience: Operates at -25°C to +70°C with conformal-coated PCBs resisting humidity, dust, and corrosive atmospheres. ATEX Zone 2 certification permits deployment in hazardous oil/gas facilities.

Typical Application Scenarios

The ABB CI854BK01 excels in multi-vendor industrial networks:

In chemical processing plants, it interfaces AC800M controllers with third-party PROFIBUS flow meters (e.g., Endress+Hauser) and valve positioners. The ABB CI854BK01’s deterministic data exchange (<1 ms cycle time) enables precise PID control of reactors while its diagnostic capabilities predict cable degradation through signal quality metrics.

For water treatment facilities, the module connects pumping station drives (ABB ACS880) to SCADA systems over PROFIBUS-DP. Redundant power inputs ensure continuous operation during grid fluctuations, while IP20-rated terminals withstand humid control cabinet environments.

In automotive assembly lines, the ABB CI854BK01 integrates robotic cells (KUKA, FANUC) into ABB’s DCS. Its support for 125 nodes per segment simplifies large-scale network architecture, reducing cabling costs by 40% versus point-to-point solutions.

ABB CI854BK01

Related Model Recommendations

PM851: ABB AC800M controller; master device for CI854BK01-managed networks.

SD822: S800 digital input module; interfaces sensors via CI854BK01’s PROFIBUS.

TB801: Terminal unit for CI854BK01; simplifies field wiring.

CI854A: Ethernet/IP counterpart to CI854BK01 for hybrid networks.

S800 I/O Baseplate (EJ801): Mounting chassis for CI854BK01.

3BSE018105R1: Redundant power supply for CI854BK01 critical applications.

ABB 1KHL 000713: PROFIBUS connector kit with terminators for CI854BK01.

Installation, Commissioning and Maintenance Instructions

Installation Preparation:

Power down the S800 baseplate before module insertion. Verify DIN rail grounding (<0.1Ω). Use shielded PROFIBUS cable (Type A) with 90Ω impedance. Terminate bus ends with active terminators. Ensure ambient temperature within -25°C to +70°C.

Maintenance Suggestions:

Quarterly: Inspect terminal tightness (0.5–0.6 Nm torque). Monitor PROFIBUS diagnostics in Control Builder for SNR margins. Annually: Clean connectors with isopropyl alcohol. Replace ABB CI854BK01 if STATUS LED flashes red/yellow. Always use ABB-approved replacement modules to maintain certifications.

Service and Guarantee Commitment

ABB provides a 36-month warranty for CI854BK01, covering material and manufacturing defects. Global technical support includes 24/7 access to ABB’s Control Builder Knowledgebase and firmware updates. On-site commissioning assistance available through ABB’s Network Integration Services. All modules undergo 72-hour burn-in testing with protocol stress validation. Extended lifecycle support guarantees spare parts availability for 15 years after discontinuation.