Description

Key Technical Specifications

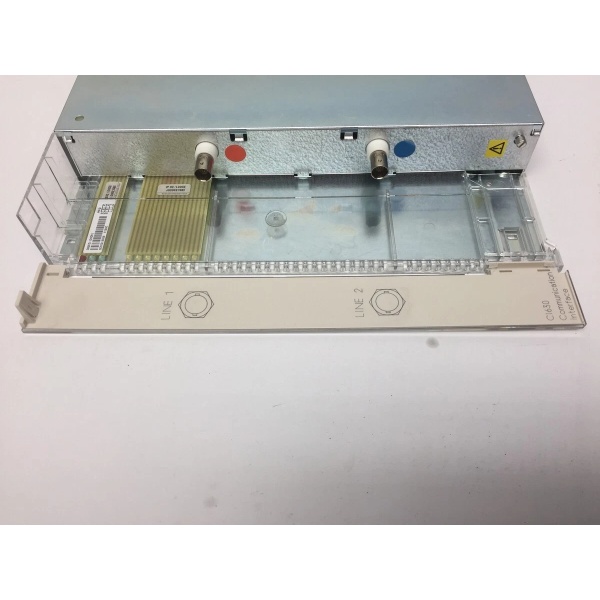

- Model Number: CI630 3BSE011000R1

- Manufacturer: ABB Process Automation

- Fieldbus Protocol: Profibus DP-V1 (compatible with DP-V0; master/slave configurable)

- Data Transfer Rate: 9.6 kbps – 12 Mbps (auto-negotiable or manual configuration)

- Max Nodes per Bus: 126 slave devices (when configured as DP master)

- Communication Port: 1× D-sub 9-pin (male) for Profibus DP connection

- Isolation Rating: 500V AC (port-to-backplane; port-to-chassis ground)

- Backplane Compatibility: ABB S800 I/O rack backplane (1-slot occupancy)

- Power Supply: 24VDC ±10% (from S800 rack power supply; 0.2A max current draw)

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Protection Rating: IP20 (rack-mounted, indoor control cabinet use only)

- Certifications: UL 508, CE, ATEX Zone 2, IEC 61010-1

ABB CI630 3BSE011000R1

Field Application & Problem Solved

In process and manufacturing plants, the biggest pain point with multi-device integration is bridging the AC 800M DCS to legacy Profibus DP field devices (e.g., variable frequency drives, motor starters, pressure transmitters). Legacy communication modules lack DP-V1 diagnostic capabilities, forcing technicians to physically inspect each device to troubleshoot faults—a time-consuming task that leads to extended downtime. A German automotive plant once lost 8 hours of production when a Profibus-connected VFD failed; without DP-V1 diagnostics, technicians couldn’t pinpoint the fault remotely.

The CI630 solves this by acting as a high-speed, diagnostic-capable gateway between the AC 800M DCS and Profibus DP networks. You’ll find it in refineries linking Profibus VFDs to pump control loops, in chemical plants integrating DP pressure sensors with reactor control systems, and in automotive lines connecting PLC-based robot cells to the central DCS. Its core value is DP-V1 support: unlike DP-V0 modules that only transmit process data, the CI630 relays device diagnostics (e.g., VFD overcurrent faults, sensor calibration errors) directly to the DCS HMI. At a Texas refinery, this feature cut VFD troubleshooting time by 80%—technicians fixed a pump drive fault remotely without opening the field cabinet.

Another critical value is its master/slave flexibility. Configure it as a master to control a network of DP slaves, or as a slave to integrate the AC 800M DCS into a larger Profibus network (e.g., with a Siemens PLC). This eliminates the need for costly third-party gateways, reducing integration costs by 30% in typical retrofit projects.

Installation & Maintenance Pitfalls (Expert Tips)

Profibus Termination Resistors Are Non-Negotiable: Rookies forget to enable the built-in 120-ohm termination resistor on the CI630 when it’s the first or last device on the bus. This causes signal reflections, leading to data corruption and bus drops. Check the module’s DIP switch settings—enable termination if the CI630 is at either end of the Profibus cable run. A chemical plant’s recurring “VFD communication loss” issue was fixed by flipping this single switch.

Baud Rate Must Be Uniform Across the Entire Bus: Technicians set the CI630 to 12 Mbps (max speed) but leave field devices at 1.5 Mbps, causing bus synchronization failures. The entire Profibus network—CI630 included—must use the same baud rate. Start with a lower rate (e.g., 1.5 Mbps) for long cable runs (>100m) and increase only if communication is stable. A refinery’s pump control loop outage was traced to mismatched baud rates between the CI630 and 12 VFDs.

Shield Grounding Prevents EMI-Induced Faults: Improper shield grounding on Profibus cables creates ground loops that introduce noise, leading to intermittent “bus timeout” faults. Ground the cable shield at the CI630 end only—grounding both ends connects two different ground potentials. Use twisted-pair shielded cable (Profibus-specific cable is preferred) and avoid routing parallel to 480V power cables. An automotive plant fixed robot cell communication drops by reconfiguring shield grounding on the CI630 bus.

Hot-Swap Requires DCS Deactivation First: The CI630 is hot-swappable, but rookies pull it from a live rack without deactivating it in Control Builder M. This crashes the Profibus bus, taking all connected devices offline. First, use the DCS software to set the module to “Out of Service,” wait 10 seconds for the bus to disconnect, then use the eject lever to remove it. This simple step prevented a 2-hour outage at a Midwest packaging plant.

ABB CI630 3BSE011000R1

Technical Deep Dive & Overview

The ABB CI630 3BSE011000R1 is a microprocessor-driven Profibus DP-V1 communication module designed to bridge the AC 800M DCS to Profibus field devices. At its core, a dedicated 32-bit ARM processor handles protocol conversion, translating Profibus DP data into the S800 backplane protocol for the DCS, and vice versa. This offloads communication tasks from the AC 800M CPU, preventing scan time overruns that degrade control loop performance.

The module’s DP-V1 support is a game-changer for diagnostics: it can read device-specific status data (e.g., VFD thermal overload, sensor calibration drift) that DP-V0 modules ignore, enabling predictive maintenance. The 12 Mbps max data rate ensures high-speed transmission of process data—critical for time-sensitive applications like robot motion control or high-speed packaging lines.

Galvanic isolation (500V AC) between the Profibus port and the S800 backplane blocks voltage surges and EMI from the field, protecting the DCS from damage. The module’s hot-swap capability is enabled by redundant power and communication connections to the backplane, allowing replacement without powering down the S800 rack. Unlike low-cost Profibus gateways, the CI630 uses industrial-grade components rated for 15+ years of operation in harsh environments, making it a reliable workhorse for process and manufacturing automation systems.