Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | CI627A 3BSE017457R1 |

| Manufacturer | ABB |

| Product category | Communication interface module |

| Communication protocols | PROFIBUS DP-V1, PROFIBUS PA |

| Data transfer rate | 9.6 kbps to 12 Mbps (configurable) |

| Number of ports | 1 x PROFIBUS DP/PA port |

| Bus type | RS485 (twisted-pair) |

| Maximum node capacity | 124 devices per segment |

| Operating voltage | 24 V DC ±15% |

| Power consumption | Max 4 W |

| Isolation | 2 kV AC (bus to backplane) |

| Operating temperature | -25°C to 70°C |

| Dimensions | 100mm × 160mm × 80mm |

| Mounting type | Backplane mount (compatible with AC800M controller) |

| Protection rating | IP20 |

| Certifications | IEC 61158, CE, UL, ATEX |

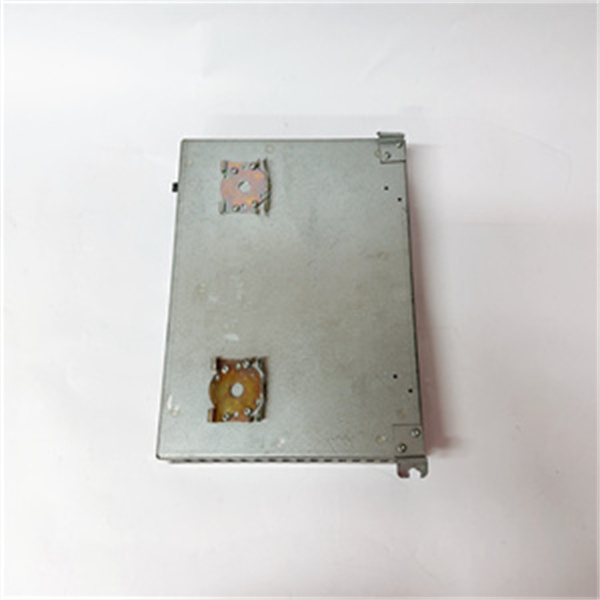

ABB CI627A 3BSE017457R1

Product introduction

The ABB CI627A 3BSE017457R1 is a high-reliability communication interface module designed to facilitate seamless data exchange between ABB’s AC800M controllers and field devices via PROFIBUS networks. As a key component in ABB’s industrial communication portfolio, ABB CI627A 3BSE017457R1 serves as a critical bridge between control systems and distributed field devices such as sensors, actuators, and variable frequency drives, ensuring efficient and secure data transmission in industrial automation environments.

ABB CI627A 3BSE017457R1 supports both PROFIBUS DP-V1 (for high-speed discrete and analog control) and PROFIBUS PA (for process automation in hazardous areas), making it versatile for diverse industrial applications. Its robust design, including 2 kV AC isolation and wide temperature tolerance, ensures reliable operation in harsh conditions, from chemical plants to power generation facilities. Whether integrated with digital input modules like the ABB RXIDK 2H 1MRK000838-HA or coordinating with PLCs such as the ABB PM633, ABB CI627A 3BSE017457R1 enables real-time communication, enhancing system responsiveness and operational efficiency.

Core advantages and technical highlights

Dual protocol support: ABB CI627A 3BSE017457R1 seamlessly handles both PROFIBUS DP-V1 and PA protocols, eliminating the need for separate interface modules in mixed applications. In a chemical plant, this allows the module to communicate with high-speed DP-V1 devices (e.g., motor starters) and PA field instruments (e.g., pressure transmitters in explosive zones) via a single interface, simplifying network architecture and reducing installation costs by up to 30%.

Flexible data rates: With configurable transfer speeds from 9.6 kbps to 12 Mbps, ABB CI627A 3BSE017457R1 adapts to application requirements—using lower rates for long-distance communication (up to 1200m at 9.6 kbps) and higher speeds for time-critical control (12 Mbps for distances up to 100m). In an automotive assembly line, this flexibility enables high-speed communication (12 Mbps) with robotic controllers while supporting slower, long-range links to material handling systems across the plant.

Robust isolation and noise immunity: Equipped with 2 kV AC isolation between the PROFIBUS bus and backplane, ABB CI627A 3BSE017457R1 protects sensitive control systems from electrical noise and ground loops common in industrial environments. This isolation is particularly valuable in steel mills or welding facilities, where electromagnetic interference can disrupt communication. The module’s differential signaling design further enhances noise rejection, ensuring data integrity even in noisy environments.

Seamless integration with ABB ecosystem: ABB CI627A 3BSE017457R1 is natively compatible with ABB’s AC800M controllers, PM633 PLCs, and Relion® protection relays, enabling plug-and-play configuration via ABB’s Automation Builder software. This integration reduces commissioning time by automating device discovery and parameter assignment. In a water treatment plant, for example, the module automatically recognizes connected RXIDK 2H digital input modules and configures communication parameters, minimizing setup errors.

Typical application scenarios

In a large-scale petrochemical plant, ABB CI627A 3BSE017457R1 connects an AC800M controller to a PROFIBUS PA network with 50 field instruments (pressure, temperature, and flow transmitters) in hazardous areas (ATEX Zone 1). The module’s support for PA protocols ensures safe, intrinsic safety-compliant communication, while its 12 Mbps DP-V1 interface links to 20 motor control centers, enabling real-time status monitoring and control. The CI627A’s robust design withstands the plant’s high ambient temperatures (up to 60°C) and chemical exposure, ensuring uninterrupted communication critical for process safety.

In a food and beverage production facility, ABB CI627A 3BSE017457R1 integrates with a PM633 PLC to coordinate a PROFIBUS DP network of 30 variable frequency drives (VFDs) and 15 RXIDK 2H digital input modules monitoring conveyor sensors. The module’s 9.6 kbps data rate optimizes communication with VFDs across the 500m plant floor, while its noise immunity prevents interference from washdown equipment. Operators use the ABB XVC517AE10 HMI to monitor drive speeds and conveyor status via data transmitted through the CI627A, enabling quick adjustments to production rates.

ABB CI627A 3BSE017457R1

Related model recommendations

ABB RXIDK 2H 1MRK000838-HA: A digital input module whose data is transmitted to controllers via ABB CI627A 3BSE017457R1.

ABB PM633: A PLC that uses ABB CI627A 3BSE017457R1 to communicate with PROFIBUS field devices.

ABB XVC517AE10 3BHB004744R0010: An HMI that displays data from field devices connected through ABB CI627A 3BSE017457R1.

ABB 200900-004: A terminal block used to terminate PROFIBUS cables for ABB CI627A 3BSE017457R1.

ABB PPE091A101 3BHE044481R0101: A redundant power supply ensuring stable 24 V DC to ABB CI627A 3BSE017457R1.

ABB TB857: A surge protection device that shields ABB CI627A 3BSE017457R1 from voltage transients on the PROFIBUS line.

Installation, commissioning and maintenance instructions

Installation preparation: Mount ABB CI627A 3BSE017457R1 into the AC800M backplane, ensuring proper alignment with connector pins. Torque the retaining screw to 0.5 Nm. Connect the PROFIBUS bus using 2-core twisted-pair cable (100Ω impedance) with shielded connectors. Ground the cable shield at both ends to the cabinet ground. Power the module via the backplane 24 V DC supply, protected by a 1A fuse. Use a torque screwdriver set to 0.5 Nm for terminal connections. Power off the system during installation to prevent electrical damage.

Maintenance suggestions: Inspect ABB CI627A 3BSE017457R1 quarterly for loose connections, dust accumulation, and LED status (power: green, bus activity: flashing yellow, fault: red). Clean ventilation slots with compressed air. Verify bus integrity semi-annually using a PROFIBUS tester to check signal strength and data rate. Test isolation resistance annually with a megohmmeter (2 kV for 1 minute) to ensure compliance with safety standards. If communication faults occur, check cable termination, bus load, and device addressing before replacing the module—use only ABB-certified replacements to maintain protocol compatibility.

Service and guarantee commitment

ABB CI627A 3BSE017457R1 is backed by a 5-year warranty from installation, covering manufacturing defects and ensuring compliance with PROFIBUS protocol specifications. ABB’s communication systems technical support team provides response within 4 hours for critical issues, with remote diagnostics available 24/7 to minimize network downtime. On-site service is available within 72 hours in major industrial regions for complex troubleshooting.

The warranty includes free access to configuration software and protocol test tools. Extended service contracts offer annual bus performance analysis and priority support, ensuring the module maintains reliable communication throughout its 15-year design lifespan. ABB’s commitment to quality underscores confidence in ABB CI627A 3BSE017457R1 as a durable backbone for industrial communication networks.