Description

Key Technical Specifications

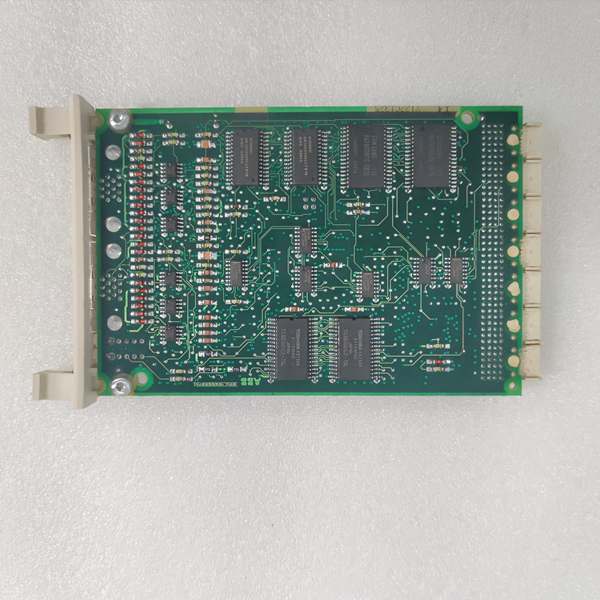

- Model Number: CI522 1SAP222200R0001

- Manufacturer: ABB Industrial Automation Division

- Protocol Support: CANopen (DS 301 v4.0, DS 302 v2.1), CAN 2.0A/B (11/29-bit identifiers)

- Baud Rate Range: 10kbps, 20kbps, 50kbps, 125kbps, 250kbps, 500kbps, 1Mbps (configurable)

- Communication Port: 1 × CANopen (DB9 female, CAN-H/CAN-L/GND)

- Power Supply: 24VDC ±10% (from AC800M rack backplane); 0.1A typical current draw

- Operating Temperature: -25°C to +65°C (-13°F to +149°F)

- Isolation Rating: 1kV AC (CANopen port to backplane); 500V AC (port-to-chassis)

- Max Nodes: 127 CANopen devices per segment (master mode); 1 slave node (slave mode)

- Compatibility: ABB AC800M CPUs (PM901F/PM902F/PM904F), AC800M I/O racks, third-party CANopen devices

- Certifications: CE, UL 508, ATEX Zone 2, RoHS 2.0, IEC 61158-3-4 (CANopen)

- Diagnostic Capability: Built-in bus status, error counters, device connection monitoring (transmitted to AC800M CPU)

ABB CI522 1SAP222200R0001

Field Application & Problem Solved

In industrial communication—refinery process loops, power plant auxiliary systems, chemical reactor control—the biggest challenge is connecting ABB AC800M DCS to CANopen field devices (e.g., smart valves, servo drives, pressure sensors). Generic CANopen modules fail due to poor compatibility with AC800M, unstable bus communication in harsh environments (noise, vibration), and lack of industrial ruggedness. A Texas refinery lost $100k in a 2.5-hour outage when a generic CANopen gateway failed, cutting off DCS communication with 15 CANopen-enabled control valves. Legacy setups also force costly workarounds: a Pennsylvania chemical plant spent $25k on external converters to bridge CANopen to the DCS, leading to 1 hour of monthly downtime from protocol translation delays.

You’ll find this module in AC800M DCS racks across: refinery alkylation units (connecting to CANopen flow control valves), coal plant ash handling systems (linking to conveyor drives), and pharmaceutical batch reactors (communicating with temperature sensors). Its core value is ABB-native integration + reliable CANopen bus control + industrial hardening. The direct AC800M backplane connection eliminates driver conflicts and latency, while 1kV AC isolation blocks electrical noise from VFDs and motors—common in refineries and power plants. For an Alaskan natural gas plant, the -25°C operating range ensured year-round reliability, unlike generic modules that failed in sub-zero temperatures.

Installation & Maintenance Pitfalls (Expert Tips)

- CANopen Termination: Mandatory 120Ω Resistor: Rookies forget to install a 120Ω termination resistor at the start/end of the CANopen bus, causing signal reflection and communication errors. A Michigan paper mill’s valve control loops were unstable until a resistor was added to the CI522 port and final device. Use ABB’s 1SFL500001R0001 termination resistor (verify with a multimeter—120Ω between CAN-H and CAN-L).

- Baud Rate Mismatch Breaks Bus Communication: Rookies set the CI522 to a different baud rate than field devices, leading to “no response” faults. An Ohio steel mill’s CANopen sensors went offline until the module’s baud rate (250kbps) was synced to the devices via Control Builder M. Document all device baud rates and configure the CI522 to match—avoid auto-baud for critical loops.

- Wiring Errors: Swap CAN-H/CAN-L: Reversing CAN-H (typically red) and CAN-L (typically black) wires prevents bus communication. A Florida food processing plant’s CANopen grippers failed to actuate until wiring was corrected. Follow ABB’s wiring diagram and label wires clearly—use a CAN bus tester to verify signal integrity after installation.

- Firmware Mismatch with AC800M CPU: Outdated CI522 firmware (pre-v5.1) with AC800M PM901F v7.0+ causes intermittent bus drops. A North Carolina refinery’s pressure sensors lost communication hourly until the module was updated via Control Builder M. Always batch-update communication modules to match the CPU firmware—mismatched versions corrupt CANopen data frames.

- Bus Loading: Avoid Overcrowding Segments: Connecting more than 32 devices per CANopen segment exceeds the bus’s electrical load capacity, causing signal degradation. A Louisiana chemical plant’s CANopen bus failed until devices were split into two segments with a repeater. Use ABB’s CANopen bus load calculator to ensure total load stays below 60% of maximum.

ABB CI522 1SAP222200R0001

Technical Deep Dive & Overview

The ABB CI522 1SAP222200R0001 is a dedicated CANopen communication module engineered to integrate ABB’s AC800M DCS with CANopen field devices, eliminating the need for external gateways. At its core, a dedicated 32-bit CAN controller processes CANopen protocol commands, translating between the AC800M’s internal backplane and the CANopen bus. This offloads communication tasks from the AC800M CPU, ensuring control loop scan times remain unaffected.

Unlike generic CANopen modules, the CI522 supports CANopen DS 301 (generic communication) and DS 302 (motion control) standards, enabling compatibility with a wide range of industrial devices. The DB9 port features 1kV AC isolation to block electrical interference from industrial noise sources, while the conformal-coated PCB protects against dust and humidity. The module auto-detects bus errors (e.g., short circuits, overcurrent) and transmits diagnostic data to the AC800M CPU, enabling predictive maintenance.

What sets it apart is its seamless integration with ABB’s Control Builder M software, allowing technicians to configure CANopen networks, map process data objects (PDOs), and monitor bus health from a single interface. For facilities relying on CANopen devices with AC800M DCS, this module isn’t just a communication interface—it’s a robust, low-maintenance bridge that ensures reliable data flow between field devices and the control system, even in the harshest industrial conditions.