Description

Key Technical Specifications

- Model Number: BSD0750

- Manufacturer: ABB Robotics & Discrete Automation

- Drive Type: Compact servo drive (current-source inverter topology)

- Output Power: 7.5kW (continuous); 15kW (peak, 10s duration)

- Input Voltage: 3-phase 380-480V AC ±10%, 50/60Hz

- Output Current: 18A (continuous); 36A (peak)

- Control Modes: Position control (electronic gearing, cam profiling), Speed control (PID regulation), Torque control (current limiting)

- Feedback Compatibility: Incremental encoder (5V TTL/HTL), resolver (4-wire), absolute encoder (optional via EtherCAT)

- Communication Interfaces: CANopen DS402, EtherCAT (CoE), Modbus RTU (optional)

- Response Time: ≤1ms (current loop); ≤5ms (speed loop); ≤10ms (position loop)

- Operating Temperature: 0°C to +40°C (ambient); derate 2%/°C above 40°C up to 50°C

- Protection Features: Overcurrent, overvoltage, undervoltage, overtemperature, short circuit, encoder fault

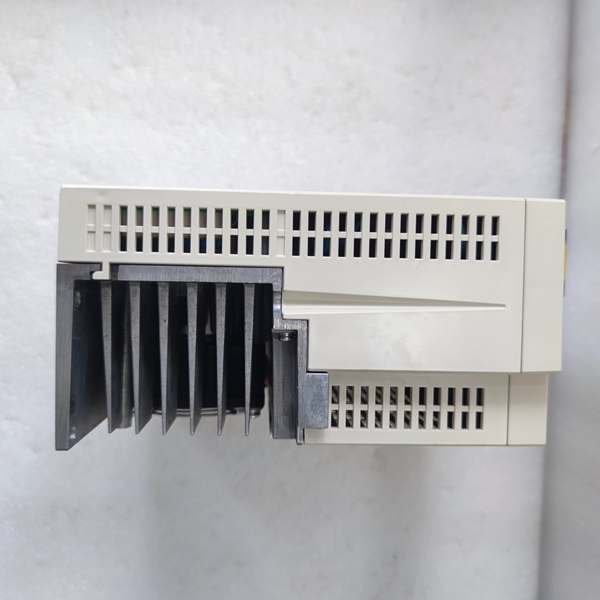

- Mounting Type: DIN rail or panel mount (IP20, indoor use)

- Weight: 2.8kg (6.2 lbs)

- Certifications: CE, RoHS compliant; UL/cUL listed

- Compatible Systems: ABB AC500 PLCs, IRC5 Robot Controllers, ABB MotiFlex e180 Servo Motors, third-party servo motors (with parameter tuning)

ABB BSD0750

Field Application & Problem Solved

In industrial motion control systems—think robotic assembly arms, packaging machine vertical form-fill-seal axes, or automotive welding line actuators—the biggest headache is integrating servo drives with existing ABB automation. Generic servo drives require custom firmware, wiring, and calibration to work with ABB PLCs, leading to communication lag, positioning errors, and frequent downtime. A Michigan automotive plant wasted $150k/year on welding fixture misalignment because generic drives couldn’t sync with their AC500 PLC, causing ±0.5mm position error. A Wisconsin packaging facility dealt with 6-hour shutdowns when third-party drives failed to communicate with ABB’s safety system, triggering production halts.

This drive eliminates that friction by being purpose-built for ABB ecosystems. You’ll find it in: robotic pick-and-place arms (maintaining ±0.02mm positioning accuracy), packaging machine film tension control axes (speed regulation with ±0.5% precision), automotive assembly line welding fixtures (synchronized motion with ABB robots), and material handling conveyors (torque control for smooth load acceleration). Its core value is ABB-native integration + multi-mode flexibility—plug-and-play compatibility with AC500 PLCs cuts setup time by 60%, and three control modes adapt to diverse motion tasks. For the Michigan plant, it dropped positioning error to ±0.03mm, eliminating fixture-related scrap. For the packaging facility, it eliminated 95% of communication-induced downtime.

Installation & Maintenance Pitfalls (Expert Tips)

- Motor Parameter Auto-Tuning: Don’t Skip It: Rookies manually enter motor parameters, leading to resonance and overshoot. An Ohio plant’s robotic arm oscillated until we ran ABB’s auto-tune function, which calibrates stator resistance, inductance, and back-EMF. Fix: Use ABB’s DriveCom software to initiate “motor identification”—the drive runs a test cycle to map motor characteristics, ensuring optimal performance.

- Feedback Wiring: Match Encoder Type to Drive Settings: Swapping encoder phase A/B wires or using HTL instead of TTL settings causes position drift. A Pennsylvania plant’s packaging machine had film misalignment until we corrected the encoder wiring and selected “HTL” in the drive’s feedback menu. Fix: Verify encoder type (TTL/HTL) matches drive parameters, use shielded twisted-pair cable for feedback, and keep it 30cm away from power cables.

- Grounding: Single-Point to ABB System Ground: Rookies ground the drive to the machine frame and the PLC to a separate bus, creating ground loops that corrupt EtherCAT signals. A Illinois plant’s drive showed “communication timeout” errors until we re-grounded both to the ABB system’s main ground bar (≤4Ω resistance). Fix: Use a dedicated ground conductor (min 16mm²) for the drive, and avoid daisy-chaining grounds.

- Overloading: Respect Peak Current Limits: Running the drive at 36A peak for more than 10 seconds burns out the power stage. A Tennessee plant’s conveyor drive failed after 3 months because they used peak current for continuous operation. Fix: Calculate load requirements (use ABB’s load calculator tool) and set current limits to 18A continuous/36A peak. Monitor drive temperature—derate if ambient exceeds 40°C.

- Firmware Compatibility: Match PLC Version: Outdated drive firmware causes communication mismatches with newer ABB PLCs. A Indiana plant’s AC500 PLC couldn’t recognize the drive until we updated the drive’s firmware to v2.3 (matching the PLC’s version). Fix: Check ABB’s Product Library for firmware updates before installation, and use DriveCom to flash the drive—never mix firmware versions in synchronized motion systems.

ABB BSD0750

Technical Deep Dive & Overview

The BSD0750 is a compact, high-performance servo drive engineered for seamless integration with ABB’s industrial motion control systems. At its core, it uses a current-source inverter topology that delivers precise current regulation—critical for servo motor torque control. The drive’s control electronics include a 32-bit microprocessor that processes feedback signals (from encoders/resolvers) and executes closed-loop control algorithms for position, speed, or torque.

The current loop (≤1ms response) provides fast torque regulation, the speed loop (≤5ms) maintains stable RPM under variable load, and the position loop (≤10ms) executes precise motion profiles (electronic gearing, cam profiling) synced with ABB PLCs. The drive’s communication interfaces (CANopen/EtherCAT) support real-time data exchange with ABB automation, eliminating lag in synchronized motion tasks.

What sets it apart from generic drives is its ABB-native compatibility: it’s pre-configured with ABB’s communication protocols (DriveCom, CANopen DS402) and works with ABB’s AC500 PLCs and IRC5 robots without custom programming. The compact DIN rail/panel mount design saves cabinet space, while protection features (overcurrent, overtemperature) prevent damage in harsh industrial environments.

For field service teams, it’s a low-maintenance workhorse: the drive includes self-diagnostics (via ABB’s PLC or DriveCom software) that flag issues like encoder faults or overvoltage, the power stage modules are replaceable in the field, and firmware updates are easily deployed via USB. Unlike generic drives, it doesn’t require specialized training to troubleshoot—ABB’s global service network provides direct support for integration with existing systems. It’s not just a servo drive—it’s a plug-and-play motion control solution that delivers the precision and reliability ABB users demand.