Description

Detailed parameter table

| Parameter name | Parameter value |

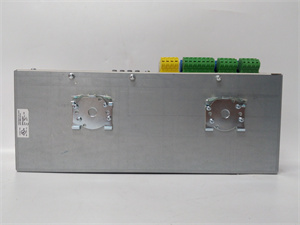

| Product model | BCU-02 |

| Manufacturer | ABB |

| Product category | Control and monitoring unit |

| Operating voltage range | 24-250 V DC or 110-240 V AC |

| Frequency range | 50-60 Hz |

| Measurement accuracy | Voltage: ±0.5%; Current: ±1% |

| Communication protocols | Modbus RTU/ASCII, Profibus DP, Ethernet (TCP/IP) |

| Data storage capacity | 16 MB (expandable to 64 MB) |

| Operating temperature range | -20°C to +60°C |

| Humidity tolerance | 0-95%, non-condensing |

| Dimensions (LxWxH) | 200 x 150 x 80 mm |

| Mounting options | DIN rail (35mm) or surface-mount |

ABB BCU-02

Product introduction

The BCU-02 is a compact yet powerful control and monitoring unit from ABB, designed to serve as the backbone of industrial automation systems. As part of ABB’s entry-level control portfolio, BCU-02 integrates real-time data acquisition, logic control, and network communication into a single device, bridging the gap between field sensors/actuators and higher-level PLCs or SCADA systems.

Ideal for small to medium-scale automation projects, BCU-02 combines versatility with user-friendly operation, making it suitable for both experienced engineers and technicians new to industrial control systems. Its ability to handle multiple input/output types and communication protocols ensures seamless integration into existing setups, while its robust design guarantees reliable performance in demanding environments. Whether deployed in manufacturing lines, building management systems, or utility grids, BCU-02 delivers precise control and actionable insights to optimize operational efficiency.

Core advantages and technical highlights

Multi-protocol compatibility: BCU-02 supports Modbus, Profibus, and Ethernet protocols out of the box, eliminating the need for additional communication modules. This flexibility allows it to connect with legacy equipment and modern smart devices alike—critical in factories undergoing gradual automation upgrades. For example, in a food processing plant, BCU-02 can communicate with a 10-year-old packaging machine via Modbus while sending real-time data to a new HMI using Ethernet, streamlining data flow across the production floor.

Enhanced measurement precision: With voltage accuracy of ±0.5% and current accuracy of ±1%, BCU-02 provides reliable data for energy management and process optimization. In a commercial building’s HVAC system, this precision enables BCU-02 to detect even minor deviations in power consumption, triggering adjustments to reduce energy waste by up to 15% compared to standard monitoring systems.

Rugged design for harsh environments: Rated to operate in temperatures from -20°C to +60°C and humidity up to 95% (non-condensing), BCU-02 thrives in challenging conditions. Its sealed housing protects internal components from dust and moisture, making it suitable for outdoor installations such as water treatment plants or solar farms. In a desert solar facility where daytime temperatures exceed 50°C, BCU-02 continues to monitor inverter performance without data loss or system shutdowns.

Expandable data storage: The 16 MB onboard memory (expandable to 64 MB) allows BCU-02 to log historical data for weeks, even at high sampling rates. This capability is invaluable for troubleshooting intermittent issues—for instance, in a conveyor system, BCU-02 can store 30 days of motor current trends, enabling engineers to identify and resolve a recurring overload issue that only occurs during peak production hours.

Typical application scenarios

In municipal water treatment plants, BCU-02 serves as a local control hub for filtration systems. It monitors pressure sensors in sand filters, flow meters in chemical dosing lines, and level switches in storage tanks, aggregating data to optimize backwashing cycles. When pressure drops below a threshold, BCU-02 automatically triggers valve actuators to initiate backwashing, reducing manual intervention and ensuring consistent water quality. Its ability to communicate with the plant’s SCADA system via Ethernet allows operators to monitor filter performance remotely, while its rugged design withstands the humid, chemically exposed environment.

In small manufacturing workshops, BCU-02 controls standalone production cells—such as a plastic injection molding station. It synchronizes the mold clamp, heater, and ejector mechanisms based on temperature and pressure readings, ensuring each part meets quality standards. During a shift change, operators can use BCU-02’s built-in interface to adjust cycle parameters without accessing the main PLC, minimizing downtime. The unit’s data logging feature also tracks production counts and machine uptime, providing managers with actionable insights to improve productivity.

Related model recommendations

BCU-03: A step-up model from BCU-02 with doubled I/O capacity and faster processing, ideal for larger systems requiring more complex logic.

AC500-eCo PM554: ABB’s compact PLC that pairs with BCU-02 in mid-sized automation projects, handling advanced control tasks while BCU-02 manages field-level operations.

TB511: A terminal block accessory designed for BCU-02, simplifying wiring of sensors and actuators in tight control cabinets.

CI854A: A Profibus-to-Ethernet gateway that extends BCU-02’s communication range, useful in factories with distributed machinery.

RTU500: ABB’s remote terminal unit that complements BCU-02 in utility applications, enabling monitoring of pipeline pressure or grid voltage in remote locations.

BCU-01: A legacy predecessor to BCU-02 with basic functionality, often replaced by BCU-02 during system upgrades for improved performance.

AI830: An analog input module that expands BCU-02’s sensing capabilities, adding support for 4-20 mA signals from pressure or temperature transducers.

ABB BCU-02

Installation, commissioning and maintenance instructions

Installation preparation: Before installing BCU-02, ensure the mounting surface (DIN rail or panel) is clean, level, and free from vibration. Use a torque wrench to secure the unit—3.5 Nm for DIN rail clips, 2.5 Nm for surface-mount screws. Verify the power supply matches the 24-250 V DC/110-240 V AC range, and use 1.5 mm² wires for signal connections, 2.5 mm² for power. Avoid routing signal wires parallel to high-voltage cables to minimize electromagnetic interference.

Maintenance suggestions: Inspect BCU-02 quarterly for loose connections or dust buildup; use compressed air (max 6 bar) to clean vents. Check firmware versions annually and update via ABB’s configuration software to access new features. If communication failures occur, first verify cable integrity and protocol settings before replacing components—BCU-02’s modular design allows easy replacement of the communication port without replacing the entire unit. Store spare fuses (500 mA slow-blow) and terminal blocks to minimize downtime during repairs.

Service and guarantee commitment

ABB backs BCU-02 with a 2-year warranty covering defects in materials and workmanship, including free replacement of faulty units. Customers benefit from global technical support via email and phone, with response times within 24 hours for critical issues. ABB’s network of certified service partners offers on-site commissioning and training, ensuring optimal setup of BCU-02 in specific applications.

For extended peace of mind, optional service contracts provide annual preventive maintenance and priority support, extending coverage up to 5 years. ABB guarantees spare parts availability for BCU-02 for 7 years post-production, ensuring long-term reliability for systems with extended lifecycles. This commitment reflects ABB’s confidence in BCU-02’s durability and its dedication to customer success.