Description

Key Technical Specifications

- Model Number: ATNT-02

- Manufacturer: ABB Robotics Division

- Safety Certifications: IEC 61508 (SIL 3), ISO 13849-1 (PL e), EN 954-1 (Cat. 4)

- Input Configuration: 2 dual-channel safety inputs (accepts NC/NO contact devices)

- Operating Voltage: 24VDC ±10% (19.2-26.4VDC)

- Input Current: 8mA per channel (max)

- Isolation Rating: 1kV AC (input circuits to control circuits); 500V AC (channel-to-channel)

- Operating Temperature: -25°C to +65°C (-13°F to +149°F)

- Mounting Type: DIN rail (35mm) or IRC5 controller rack-mount (1U height)

- Enclosure Protection: IP20 (control cabinet use)

- Compatibility: ABB IRC5 Compact/Panel/MultiMove controllers, IRB 120/4600/6700/7600 robots, third-party safety devices (E-stops, light curtains)

- Certifications: CE, UL 508, ATEX Zone 2, RoHS 2.0

- Diagnostic Capability: LED status indicators (power, normal, fault), non-volatile trip cause memory, open/short circuit detection

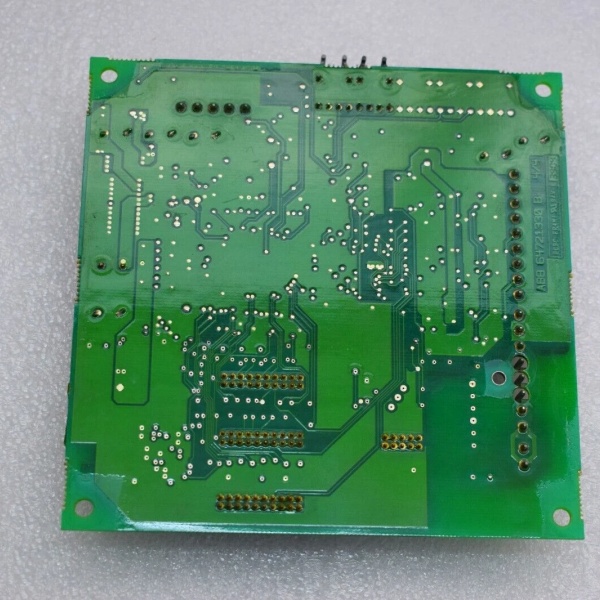

ABB ATNT-02

Field Application & Problem Solved

In industrial robot cells—automotive welding, material handling, electronics assembly—safety interlocks are the last line of defense against worker injury. The biggest field challenge is finding a safety module that integrates seamlessly with ABB IRC5 controllers while meeting SIL 3/PL e compliance. Generic safety modules fail to communicate reliably with IRC5, causing either catastrophic failure to trigger a shutdown (risking OSHA fines) or nuisance trips that halt production. A Detroit auto plant was fined $230k after a generic module failed to detect an open safety door, allowing a worker to enter a live IRB 6700 welding cell. A North Carolina food processing plant lost $45k in annual downtime from generic modules tripping falsely during robot startup surges.

You’ll find this module protecting: IRB 4600 material handling cells, IRB 6700 welding lines, and IRB 120 assembly stations in electronics plants. It’s also standard in robot cells where safety audits are frequent (pharmaceuticals, aerospace). Its core value is ABB-native integration + SIL 3 reliability + fail-safe dual-channel design. Unlike generics, it communicates directly with the IRC5 backplane, eliminating latency and ensuring the robot halts within 5ms of a safety fault. For a Texas aerospace plant, the ATNT-02’s ability to accept both NC and NO inputs simplified retrofitting older light curtains, avoiding $18k in new safety device costs.

Installation & Maintenance Pitfalls (Expert Tips)

- Dual-Channel Wiring Is Non-Negotiable: Rookies wire safety devices to a single channel to save time, voiding SIL 3 certification. A Cincinnati metal fabricator failed a safety audit until technicians rewired all E-stops to both channels. Each safety device (e.g., door switch) must connect to both channels of an input pair—this detects broken wires or loose connections that single-channel wiring misses.

- Voltage Mismatch: Never Mix AC/DC: The ATNT-02 is strictly 24VDC—rookies who wire 110VAC to inputs fry the module instantly. A Pittsburgh plastics plant destroyed two units ($1,100 total) before verifying the control panel’s voltage. Use a multimeter to confirm 24VDC at the terminals—label wires clearly to avoid cross-wiring.

- Grounding: Isolate Safety Circuits: Sharing the module’s ground with robot power circuits introduces noise, causing false fault triggers. A Milwaukee paper mill’s robot cell shut down hourly until a dedicated 10mm² safety ground bar was installed (ground resistance <1Ω). Keep safety grounds separate from VFD, motor, or PLC grounds—use shielded cable for input wiring and ground the shield at the module end only.

- Firmware Sync with IRC5: Outdated ATNT-02 firmware (pre-v4.1) causes communication drops with IRC5 v7.0+. A Columbus auto plant’s safety interlocks failed to log faults until the module was updated via RobotStudio. Always match the module’s firmware to the controller’s—mismatched versions corrupt safety status data sent to the IRC5.

- Functional Testing Post-Installation: Rookies assume “plug-and-play” works, but untested wiring errors lead to near-misses. After installation, use a multimeter to simulate open/short circuits on each channel—verify the module triggers a robot shutdown and logs the fault. A Cleveland electronics plant missed a crossed wire during installation, leading to a near-miss when a light curtain didn’t stop the robot.

ABB ATNT-02

Technical Deep Dive & Overview

The ABB ATNT-02 is a fail-safe safety relay module engineered to enforce robot cell safety by monitoring critical interlock devices and communicating directly with ABB IRC5 controllers. At its core, a dual-channel monitoring circuit checks the status of safety inputs in real time—both channels must agree on the device’s state (open/closed) for the robot to operate. If one channel detects a fault (e.g., broken wire, short circuit), the module sends a hardwired shutdown signal to the IRC5, halting all robot motion within 5ms—faster than generic modules’ 20ms response time.

Unlike generic safety modules, the ATNT-02 features 1kV AC isolation between input circuits and the IRC5 backplane, blocking electrical noise from robot motors and VFDs that cause false trips. Its dual-channel design is inherently fail-safe: a single component failure (e.g., a blown fuse in one channel) triggers a shutdown, rather than masking the fault. The module’s non-volatile memory stores the last trip cause, accessible via LED indicators—no external software needed to diagnose issues.

What sets it apart is its seamless integration with the IRC5 ecosystem. It plugs into the controller’s rack without adapters, and safety status (normal/fault) is visible in RobotStudio for remote monitoring. The ATNT-02 doesn’t just meet safety standards—it’s engineered to work with ABB robots specifically, eliminating the compatibility headaches of generic modules. For facilities where robot safety directly impacts worker well-being and production uptime, this module isn’t just a safety component—it’s a regulatory-compliant, low-maintenance solution that keeps robot cells operating safely and efficiently.