Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

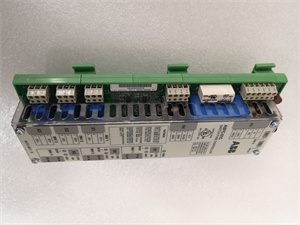

| Product Model | ABB ASFC-01C |

| Manufacturer | ABB |

| Product Category | Analog Signal Conditioning Module |

| Signal Type | 4-20 mA / 0-10 V DC (configurable) |

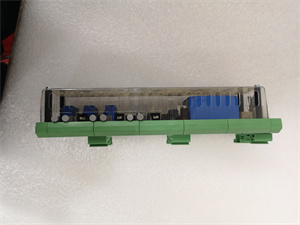

| Channels | 8 channels (isolated) |

| Isolation Voltage | 1500 V AC (channel-to-channel/channel-to-ground) |

| Accuracy | ±0.05% of span (typical) |

| Bandwidth | 2.5 kHz (-3 dB) |

| HART Support | Yes (pass-through) |

| Power Supply | 24 V DC (18-32 V DC range) |

| Power Consumption | 1.2 W (typical) |

| Operating Temperature | -40°C to +70°C |

| Communication Interface | S+ BUS (Symphony Plus DCS integration) |

| Safety Certification | SIL 2 (IEC 61508) |

ABB ASFC-01C

Product Introduction

The ABB ASFC-01C is a high-precision analog signal conditioning module integral to ABB’s Symphony™ Plus distributed control system (DCS). Designed for critical process industries, this module interfaces with field instruments—transmitters, sensors, and actuators—converting raw analog signals into standardized, noise-resistant data for the control system. Its core function lies in ensuring signal integrity across 8 isolated channels, supporting both current (4-20 mA) and voltage (0-10 V DC) inputs while enabling HART® digital communication for advanced device diagnostics.

As part of ABB’s S+ I/O family, the ABB ASFC-01C operates within Harmony/INFI90 and Symphony Plus architectures, serving as the frontline defense against signal degradation in electrically harsh environments. Technically positioned as a signal integrity guardian, it eliminates ground loops, suppresses electromagnetic interference (EMI), and provides galvanic isolation. This module transforms raw field data into reliable inputs for controllers, safeguarding decision-making accuracy in safety and regulatory-critical applications. The ABB ASFC-01C is indispensable for maintaining process stability, data fidelity, and system resilience.

Core Advantages and Technical Highlights

The ABB ASFC-01C excels in signal integrity, adaptability, and seamless DCS integration, offering distinct advantages for mission-critical automation:

Ultra-High Signal Fidelity: With ±0.05% accuracy and 1500 V AC isolation, the ABB ASFC-01C eliminates signal drift and cross-talk. Its 2.5 kHz bandwidth ensures rapid response to dynamic process changes, while integrated EMI/RFI filtering rejects noise from variable frequency drives (VFDs) and power systems.

HART®-Enabled Diagnostics: The module supports HART® 7 protocol pass-through, allowing bidirectional communication with smart field devices. This enables remote calibration, real-time device health monitoring, and predictive maintenance without disrupting control logic—reducing downtime and technician exposure in hazardous areas.

Seamless Symphony Plus Integration: Native compatibility with ABB’s S+ BUS ensures plug-and-play installation within Symphony Plus DCS. Configuration via Control Builder MT engineering tools simplifies deployment, while automatic signal validation reduces commissioning time. Hot-swappable design permits module replacement without system shutdown.

Extreme Environmental Resilience: Rated for -40°C to +70°C operation, the ABB ASFC-01C withstands temperature swings, humidity, and vibration in industrial settings. Its SIL 2 certification (extendable to SIL 3 via system design) ensures compliance with functional safety standards for fire/gas and emergency shutdown systems.

Scalable Channel Management: Individual channel configuration allows mixed signal types (mA/V) within one module. Fail-safe default states and open-wire detection enhance operational safety during faults.

Typical Application Scenarios

The ABB ASFC-01C is deployed where signal accuracy determines safety and efficiency:

Power Generation: In coal/gas plants, it conditions boiler pressure, turbine vibration, and emissions data. The ABB ASFC-01C ensures SIL 2-compliant inputs for burner management systems (BMS), preventing meltdowns during load shifts. HART® diagnostics enable remote validation of critical valve positioners.

Oil & Gas Refining: For crude distillation columns, the module isolates temperature/pressure signals from thermocouples and pressure transmitters. Its EMI immunity prevents false trips from electrical noise in compressor stations, while galvanic isolation mitigates cathodic protection interference in pipelines.

Chemical Processing: In batch reactors, the ABB ASFC-01C handles corrosive process loops (e.g., pH, chlorine flow). Channel-specific calibration compensates for sensor drift, and HART® alerts flag fouled electrodes before batch contamination occurs.

Water Treatment: Monitors pump discharge pressure, filter differential pressure, and chemical dosing rates. The module’s moisture resistance suits wastewater facilities, and open-wire detection alerts operators to broken sensor cables in unmanned sites.

ABB ASFC-01CABB ASFC-01C

Related Model Recommendations

ABB DSDO-01: Digital output module for actuating valves/relays; complements ASFC-01C in control loops.

ABB DSDI-01: 16-channel digital input module; ideal for integrating status signals within the same S+ I/O rack.

ABB AINT-02: Advanced interface module; extends ASFC-01C connectivity to third-party PLCs via Modbus TCP.

ABB NIS-22: Network interface module; aggregates data from multiple ASFC-01C units for plant-wide visualization.

ABB AC800M: Controller; processes signals from ASFC-01C for complex regulatory control.

ABB CI871: PROFIBUS adapter; enables ASFC-01C integration into legacy PROFIBUS DP networks.

Installation, Commissioning and Maintenance Instructions

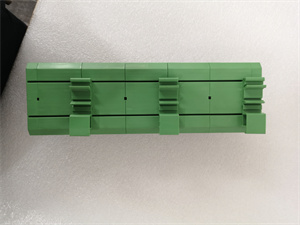

Installation Preparation: Mount the ABB ASFC-01C in a Symphony Plus S+ I/O rack (HTTA-01/HTTW-01) using DIN rail clips. Verify ambient temperature (<70°C) and humidity (<95% non-condensing). Use shielded twisted-pair cables (AWG 16-22) for field connections. Ground shields at the module’s termination point only. Isolate power during installation; use ESD wrist straps. Ensure 24V DC supply stability (±5%).

Maintenance Suggestions: Quarterly, inspect terminals for corrosion and verify torque (0.5 N·m). Annually, validate signal accuracy via HART® calibrator. Monitor module health via Control Builder MT’s diagnostic logs (channel errors, supply voltage). Replace if LED status indicates critical fault (steady red). Keep spare ABB ASFC-01C modules on-site for hot-swap during failures. Update firmware via S+ BUS during planned shutdowns.

Service and Guarantee Commitment

ABB guarantees the ABB ASFC-01C for 18 months from shipment, covering material and workmanship defects. Global technical support is available 24/7 via ABB’s ServicePort, providing firmware updates, configuration assistance, and failure analysis. On-site commissioning and training services ensure optimal integration into Symphony Plus DCS. Lifecycle management includes 15+ years of spare parts availability and migration services to next-gen platforms. Compliance certificates (IECEx, ATEX, SIL) are provided with documentation. ABB’s commitment to Mean Time Between Failure (MTBF) >250,000 hours underscores product reliability for mission-critical operations.