Description

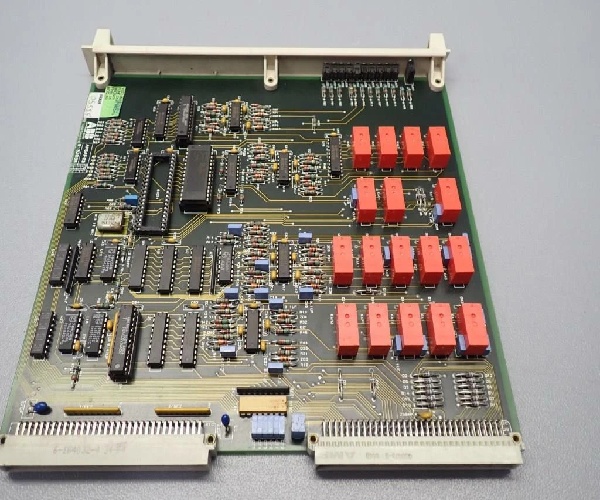

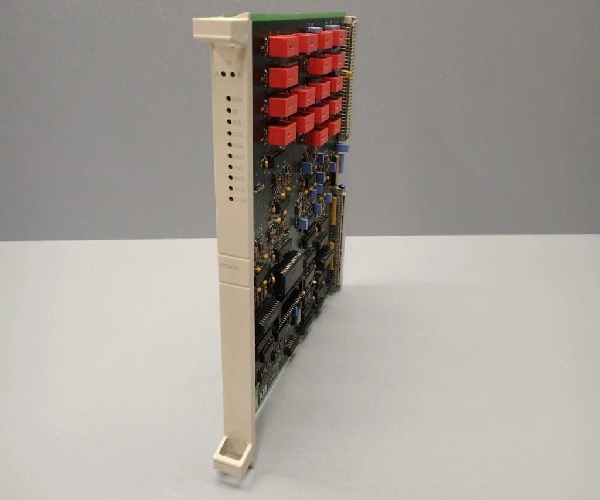

APSAF-03: Product Overview

The APSAF-03 serves as the dedicated safety control unit for ABB industrial robot systems, primarily integrated with IRC5 robot controllers to provide comprehensive safety monitoring and protection. Positioned as the “safety brain” of the robot automation cell, it acts as an independent safety layer between the standard robot controller and the physical robot motion system, ensuring compliance with international safety standards (ISO 13849-1, IEC 61508)ABB Group.

Its core functionality revolves around processing critical safety signals, including emergency stop (E-Stop) buttons, safety gate interlocks, light curtains, and two-hand control devices. The board executes predefined safety logic to immediately halt robot motion when hazardous conditions are detected, preventing collisions, entrapment, or other dangerous scenarios. It maintains constant communication with the robot controller via a dedicated safety bus, providing status updates while remaining isolated from standard control functions to prevent unintended interactions.

As part of ABB’s comprehensive robotics safety ecosystem, the APSAF-03 inherits the platform’s reputation for reliability and compliance. It is specifically designed for medium-to-large industrial robots used in manufacturing environments, offering a cost-effective safety solution that integrates seamlessly with existing ABB robot infrastructure without requiring extensive reconfiguration. The board’s modular design allows for flexible safety configuration to match specific application requirements, from simple material handling to complex assembly operations.

ABB APSAF-03

APSAF-03: Technical Specifications

- Model Number: APSAF-03 (Alternative P/N: E-32086, 3E032086)

- Manufacturer: ABB Robotics Division

- Compatible Controller: ABB IRC5 robot controller series

- Safety Certification: SIL 2 (IEC 61508), PL d (ISO 13849-1)

- Safety Input Channels: 8 configurable safety input channels (24 VDC, PNP/NPN selectable)

- Safety Output Channels: 4 safety output channels (24 VDC, 2A per channel)

- Communication Interface: ABB Safety Bus (dedicated to IRC5 controller)

- Response Time: ≤10ms for emergency stop processing

- Power Supply: 24 VDC ±10%, maximum current consumption 1.2A

- Operating Temperature: 0°C to 45°C

- Storage Temperature: -25°C to 65°C

- Protection Class: IP20 (panel mounting)

- Mounting Type: IRC5 controller chassis mounting (DIN rail compatible)

- Weight: 0.85 kg (1.87 lbs)

- Diagnostic Features: Safety fault logging (50 historical events), channel status monitoring, power supply diagnostics

- Safety Functions: Emergency stop (E-Stop), safety gate monitoring, light curtain interface, two-hand control validation

Core Features & Customer Value

Independent Safety Architecture: The APSAF-03 operates as a separate safety layer from the standard robot controller, ensuring that safety functions remain active even if the main controller experiences a fault. For manufacturing facilities, this means compliance with strict safety regulations and reduced risk of workplace accidents, which translates to lower insurance costs and improved employee morale. The SIL 2/PL d certification provides confidence that the safety system meets global industrial standards, facilitating international market access for products manufactured using ABB robots.

Configurable Safety I/O: With 8 safety input channels and 4 safety output channels, engineers can customize the safety system to match specific application requirements, from simple machine tending cells with basic E-Stop protection to complex assembly lines with multiple safety interlocks. This flexibility eliminates the need for custom safety solutions, reducing engineering time and procurement costs while ensuring future-proofing for production line modifications.

Integrated Diagnostics & Monitoring: Built-in fault logging and real-time status monitoring allow maintenance teams to quickly identify safety system issues (e.g., open safety gates, faulty E-Stop buttons, communication failures) without manual troubleshooting. Detailed diagnostic information is accessible via the robot controller’s HMI, reducing mean time to repair (MTTR) and minimizing production downtime. This feature is particularly valuable in high-volume manufacturing environments where even short stoppages can result in significant financial losses.

Seamless ABB Ecosystem Integration: The APSAF-03 is specifically designed for plug-and-play integration with ABB IRC5 robot controllers, requiring minimal configuration beyond safety parameter setup. This compatibility ensures reliable communication between the safety board and robot controller, eliminating integration issues common with third-party safety solutions. For system integrators, this translates to faster project commissioning and reduced on-site support requirements, improving overall project profitability.

ABB APSAF-03

Typical Applications

The APSAF-03 is ideally suited for safety-critical industrial robot applications across multiple industries, where human-robot collaboration or proximity demands robust safety protection. In automotive manufacturing facilities, it is widely used in body-in-white welding cells, where robots work in close proximity to human operators loading/unloading parts. The board processes signals from safety light curtains and safety gates surrounding the robot cell, ensuring immediate motion cessation if an operator enters the restricted area, preventing potentially fatal collisionsABB Group.

In electronics assembly plants, the APSAF-03 provides safety interlock protection for small-parts handling robots, monitoring emergency stop buttons and safety door interlocks on automated workstations. Its fast response time (≤10ms) is critical for preventing injuries during high-speed assembly operations, where robots move at velocities exceeding 2m/s. The board’s configurable I/O channels allow integration with specialized safety devices like two-hand control stations for manual load/unload operations, ensuring operators maintain safe positioning during interaction with the robot.

In food and beverage packaging facilities, the APSAF-03 safeguards palletizing and depalletizing robot cells, processing signals from safety scanners that detect human presence in the robot’s workspace. The board’s compliance with food industry hygiene standards (IP20 protection, sealed components) makes it suitable for wet or dusty environments common in food processing plants. Its ability to integrate with multiple safety devices simultaneously allows for comprehensive protection of complex packaging lines with multiple robot cells and human-machine interfaces.

In aerospace manufacturing, the APSAF-03 is used in composite material layup robot systems, where precise safety control is essential for protecting high-value components and human operators. The board monitors safety interlocks on robot enclosures and emergency stop buttons located at multiple positions around the work cell, ensuring rapid shutdown in case of equipment malfunction or operator intervention. Its SIL 2 certification meets the stringent safety requirements of the aerospace industry, providing traceable safety compliance documentation for regulatory audits.