Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | AO815 |

| Manufacturer | ABB |

| Product Category | Analog Output Module |

| Series | S800 I/O (AC 800M/800xA Platform) |

| Output Channels | 16 channels |

| Output Type | 4–20 mA (HART-enabled) |

| Resolution | 15-bit (including sign) |

| Accuracy | ±0.1% of span (at 25°C) |

| Load Range | 0–850 Ω (24 VDC compliance) |

| Isolation | 1500 V AC (channel-to-system) |

| HART Support | Yes (via CMA135 multiplexer) |

| Update Rate | 10 ms per channel (max) |

| Field Connection | Removable spring terminal block |

| Power Consumption | ≤ 3.5 W (24 VDC) |

| Operating Temperature | -25°C to +70°C |

| Certifications | CE, UL, cULus, ATEX Zone 2 |

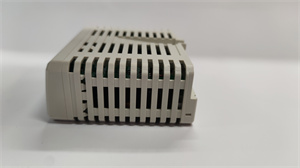

ABB AO815

Product Introduction

The ABB AO815 is a high-density, HART-compatible analog output module integral to ABB’s S800 I/O family. Designed for precision control in process automation, it converts digital commands from controllers (e.g., AC 800M or PM865) into 4–20 mA signals to regulate field devices like control valves, variable-speed drives, and actuators. With 16 isolated channels in a single slot, the AO815 optimizes cabinet space while maintaining ABB’s hallmark reliability.

As a key enabler of closed-loop control strategies, the ABB AO815 integrates natively with ABB’s Control Builder M engineering environment. Its technical design targets critical process industries where accurate analog signaling ensures stable operations. The module supports seamless HART communication when paired with ABB’s CMA135 multiplexer, allowing access to secondary variables and device diagnostics without additional wiring.

Core Advantages and Technical Highlights

The ABB AO815 delivers exceptional performance through these innovations:

High-Density Precision: Sixteen 15-bit resolution outputs in one module reduce footprint and cost per channel. ±0.1% accuracy ensures precise control of sensitive processes like reactor temperature or pH neutralization.

Integrated HART Capability: Native support for HART signal superposition enables communication with smart field devices via ABB’s CMA135 module. This unlocks remote calibration, diagnostics, and multivariable access (e.g., valve position + temperature).

Robust Electrical Protection: 1500 V AC isolation protects control systems from ground faults and surges. Short-circuit protection per channel prevents damage during field wiring faults.

Flexible Load Handling: Drives loads up to 850 Ω at 24 VDC, compatible with long cable runs and high-impedance actuators. Automatic cable compensation minimizes voltage drop errors.

Hot-Swap & Redundancy Ready: Supports live insertion/removal in redundant S800 racks, enabling maintenance without process interruption.

ATEX Zone 2 Compliance: Certified for hazardous areas, ensuring safety in oil/gas and chemical applications.

Typical Application Scenarios

Process Control (Oil & Gas): Regulates control valves in refining units for flow/pressure management. HART integration via AO815 monitors valve health to predict stiction or seal failure.

Pharmaceutical Manufacturing: Precisely adjusts dosing pumps for reagent injection. Audit trail compliance (FDA 21 CFR Part 11) is simplified through integrated HART data logging.

Power Plant Optimization: Controls feedwater valves in boilers and cooling systems. The module’s ±0.1% accuracy maintains steam pressure stability during load changes.

Water Treatment: Manages chemical dosing pumps and filtration backwash cycles. High channel density reduces hardware needs in large-scale plants.

Food & Beverage: Adjusts variable-speed conveyors and filler machines. Spring terminals resist vibration in hygienic washdown environments.

ABB AO815

Related Model Recommendations

AI835: 16-channel analog input module; complements AO815 for monitoring sensors.

CMA135: HART multiplexer; extracts digital data from AO815-connected devices.

SA811: S800 baseplate; hosts AO815 and provides power/bus connectivity.

AO810: Legacy 8-channel analog output module; upgraded by AO815‘s higher density.

AO840: Diagnostic analog output module with per-channel status feedback.

PM865: AC 800M controller; sources control signals for AO815 outputs.

CI854A: Profibus DP interface; links AO815-equipped I/O to networks.

TA-AO…: ABB analog output terminal blocks; simplify field wiring.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Mount ABB AO815 on an SA811 baseplate within specified temperature limits. Use shielded twisted-pair cables grounded at one end. Verify HART resistor (250 Ω) is installed in series if using CMA135. Ensure stable 24 VDC power (±10%). Apply ESD precautions during handling.

Maintenance Suggestions: Calibrate outputs biannually using precision current meters. Monitor channel diagnostics via Control Builder M for overloads or open circuits. Replace modules showing >0.2% drift. For HARD applications, validate CMA135 communication integrity quarterly. Update firmware during planned shutdowns.

Service and Guarantee Commitment

ABB warrants the AO815 for 18 months against defects. Global support includes:

24/7 technical assistance for troubleshooting

Firmware updates via ABB Service Portal

Repair services with 10-year spare parts availability

ATEX recertification support

Extended warranties (up to 5 years) cover priority replacement and on-site engineering. Compliance with IEC 61000-6-2/6-4 EMC standards ensures resilience in electrically noisy environments.