Description

Key Technical Specifications

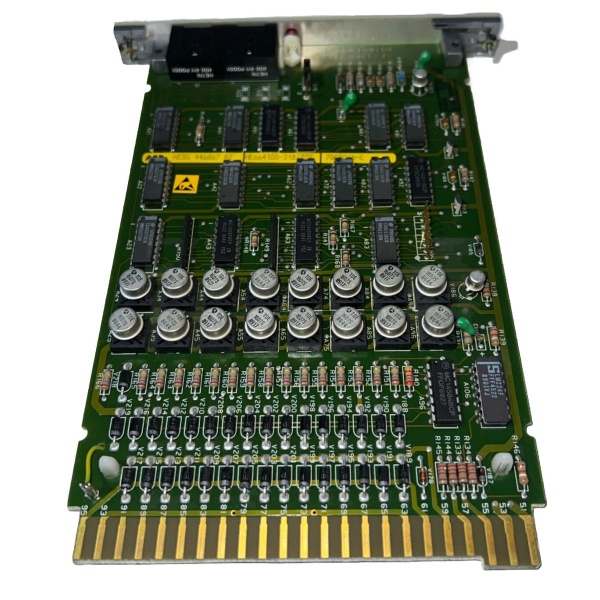

- Model Number: 70AB01b-E

- Manufacturer: ABB (legacy BBC Brown Boveri design)

- System Compatibility: ABB Procontrol P13 Distributed Control System

- Output Channels: 8 independent, galvanically isolated channels

- Output Technology: MOSFET solid-state (no moving parts)

- Rated Supply Voltage: 24V DC (process voltage UP)

- Max Channel Current: 500 mA (continuous, 24V DC)

- Max Total Module Current: 4 A (all channels active)

- Isolation Rating: 500V AC (field-to-logic; channel-to-channel)

- Inductive Load Protection: Integrated varistors (suppresses voltage spikes)

- Leakage Current: <0.5 mA (channel OFF state)

- Operating Temperature: -25°C to +60°C (industrial grade)

- Mounting: Rack-mounted (Procontrol P13 cabinet local bus slot)

- Status Indicators: 8 yellow channel LEDs (ON = output high), 1 green power LED

Field Application & Problem Solved

In power plant and refinery environments, controlling inductive loads like solenoid valves and motor starters is a constant battle against voltage spikes and premature component failure. Legacy relay-based output modules suffer from mechanical wear, short lifespans, and slow response times—leading to unplanned downtime during critical process runs. Additionally, unprotected outputs are prone to damage from inductive kickback, which can take an entire control loop offline in seconds.

The 70AB01b-E solves these pain points by delivering solid-state switching with built-in varistor protection, eliminating both mechanical wear and inductive spike damage. You’ll find this module in Procontrol P13 systems controlling boiler feedwater valves, turbine lube oil pump relays, and generator safety interlocks—applications where failure is not an option. Its core value lies in reliability: the MOSFET design offers a 10x longer MTBF (Mean Time Between Failures) than electromechanical relays, withstanding over 100 million switching cycles in typical use.

For maintenance teams, the per-channel status LEDs are a game-changer. Instead of tracing wires or using multimeters to verify output status, technicians can diagnose a faulty channel in seconds by checking the LED—cutting troubleshooting time by 60% during emergency outages. The module’s compatibility with Procontrol P13’s local bus also enables real-time diagnostic data transmission to the DCS, alerting operators to incipient failures (like rising leakage current) before they cause process upsets.

Installation & Maintenance Pitfalls (Expert Tips)

Leakage Current Checks Are Non-Negotiable

Rookies often skip checking leakage current when commissioning the module. A MOSFET with degraded insulation will have leakage current exceeding 0.5 mA, which can keep a low-power solenoid valve partially energized—causing erratic process behavior. My rule: Use a microammeter to test leakage current on every channel (with the module OFF) during installation and annual maintenance. Replace the module immediately if leakage exceeds 1 mA—this is a silent failure waiting to happen.

Ignoring Wire Gauge Causes Voltage Drop

Using undersized wires to connect field devices to the 70AB01b-E leads to voltage drop, especially in long cable runs (>50m). This reduces the effective voltage to the load, causing valves to stick or relays to fail to actuate. The fix: Use 1.5 mm² copper wire for runs up to 100m—this ensures voltage drop stays below 2% at full load (500 mA). Never use stranded wire without crimp terminals; loose strands cause intermittent connections and overheating.

Varistors Don’t Replace Flyback Diodes for Large Loads

The module’s built-in varistors handle small inductive spikes, but they’re no match for large motors or high-voltage solenoids. I’ve seen modules fail within months when controlling 24V DC motors without external flyback diodes. The solution: Install a 1N4007 diode in parallel with any inductive load over 200 mA, with the diode’s cathode connected to the positive terminal of the load. This redirects large voltage spikes away from the MOSFET output stage.

Hot Swap Requires Bus Lockout

The 70AB01b-E is listed as “hot-swappable,” but rookies often swap it without locking the Procontrol P13 local bus. This causes bus parity errors and can corrupt the DCS’s configuration data. My recommendation: Always engage the bus lockout switch on the cabinet before hot-swapping the module—this isolates the slot from the bus and prevents data corruption. Verify bus communication is restored by checking the DCS diagnostic logs after reinstallation.

ABB 70AB01b-E

Technical Deep Dive & Overview

The 70AB01b-E is a microprocessor-controlled solid-state digital output module engineered for ABB’s Procontrol P13 system, a staple in power generation and heavy process industries for over three decades. It connects to the Procontrol P13 local bus via a 96-pin edge connector, receiving output commands from the system’s main processor and transmitting status feedback (channel ON/OFF, fault flags) back to the DCS.

Internally, each of the 8 channels uses a high-power MOSFET to switch 24V DC power to the field load. A dedicated varistor across each MOSFET suppresses voltage spikes generated when inductive loads are de-energized, protecting the module from damage without external surge protectors for most applications. The module’s logic circuits are powered by the Procontrol P13 system’s 5V DC bus, while the output stages use an independent 24V DC process supply—ensuring logic operation is unaffected by field power fluctuations.

The per-channel yellow LEDs are hardwired directly to the MOSFET output, providing a fail-safe visual indicator of channel status—unlike software-based indicators, they work even if the module loses communication with the DCS. The module’s 500V AC isolation between channels and the logic circuit prevents ground loops and cross-talk, critical in noisy industrial environments with high-voltage equipment nearby. In the field, this module is a workhorse: its solid-state design and robust protection features make it ideal for applications where reliability and uptime are measured in millions of dollars per hour.