Description

Key Technical Specifications

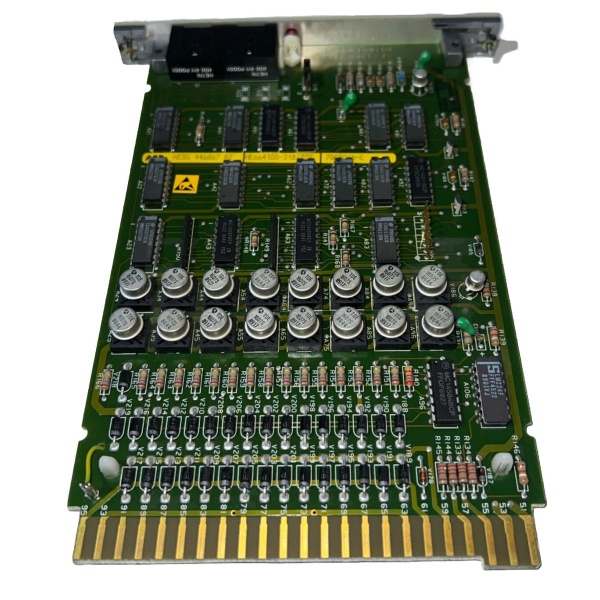

- Model Number: 70AB01b-E

- Manufacturer: ABB (formerly BBC Brown Boveri)

- System Compatibility: ABB Procontrol P13 Automation System

- Number of Channels: 8 independent digital output channels

- Output Type: Solid-state (MOSFET), non-protected (external fuse required)

- Rated Output Current: 500 mA per channel at 24V DC

- Maximum Total Current: 4 A (all channels combined)

- Operating Voltage: 24V DC (process supply voltage UP)

- Isolation Rating: 500V AC (field-to-logic, channel-to-channel)

- Leakage Current: <0.5 mA (with signal 0)

- Inductive Load Protection: Internal varistors for demagnetization

- Operating Temperature Range: -25°C to +60°C (industrial grade)

- Dimensions: 160mm x 100mm x 25mm (standard Procontrol P13 module size)

- Mounting: Rack-mounted in Procontrol P13 cabinets (local bus connection)

- Status Indicators: 1 yellow LED per channel (ON when output is high), power LED (green)

- Alternate Part Numbers: HESG446867R2, HESG446867R0002

Field Application & Problem Solved

In power generation and heavy process industries, the biggest challenge with digital output modules is reliable switching of inductive loads (valves, motors, solenoids) in harsh electrical environments. Field engineers constantly battle with: 1) voltage spikes from inductive load de-energization damaging output channels, 2) limited current capacity causing module overheating, and 3) lack of diagnostic feedback leading to prolonged troubleshooting.

The 70AB01b-E solves these problems by providing 8 isolated solid-state output channels with built-in varistor protection for inductive loads—eliminating the need for external surge protection devices in most applications. You’ll typically find this module in power plants controlling boiler feedwater valves, turbine lube oil pumps, generator cooling systems, and safety interlock relays. It’s also widely used in refineries for process heater control and chemical plants for reactor temperature regulation.

Its core value lies in preventing costly downtime through reliable operation and clear diagnostic feedback. The per-channel LEDs allow for instant visual verification of output status during troubleshooting, reducing fault-finding time by 50% compared to modules without individual channel indicators. The solid-state design provides 10x longer lifespan than electromechanical relay outputs, with MTBF (Mean Time Between Failures) exceeding 100,000 hours in typical power plant environments.

For maintenance teams, the 70AB01b-E’s modular design enables hot-swapping during scheduled outages, minimizing system downtime. Its compatibility with Procontrol P13’s local bus ensures seamless integration with the system’s main processors, providing real-time status updates to the DCS for predictive maintenance programs.

Installation & Maintenance Pitfalls (Expert Tips)

External Fusing Prevents Catastrophic Failure

A rookie mistake that has destroyed countless 70AB01b-E modules: omitting external fuses on each output channel. The module is non-protected, and a short circuit in a field device will immediately damage the solid-state output stage. My rule: Always install 3A fast-acting fuses on each channel (use DIN rail-mounted fuse blocks for easy replacement). During commissioning, test each channel by intentionally short-circuiting (with proper safety precautions) to verify fuse operation before connecting critical loads.

Varistor Protection is Not a Substitute for Proper Wiring

While the 70AB01b-E has internal varistors for inductive load protection, these only handle small voltage spikes. In the field, I’ve seen modules fail when controlling large motors or solenoids due to improper wiring of inductive loads. The fix: Install external flyback diodes (1N4007 or equivalent) in parallel with inductive loads, with the diode cathode connected to the positive terminal. This redirects large voltage spikes away from the module’s output channels.

Common Grounding Ruins Signal Integrity

The 70AB01b-E’s reference potential (ZP terminal) must be connected to a clean, single-point ground. Rookies often connect ZP to the same ground as high-power equipment, creating ground loops that introduce noise and cause erratic output behavior. The solution: Use a dedicated control system ground bus separate from power grounds. For Procontrol P13 systems, connect ZP to the cabinet’s main ground terminal, which should be bonded to the plant’s earth ground at only one point.

Overloading Channels Causes Silent Failures

Exceeding the 500 mA per channel rating doesn’t always trigger immediate failure—it often causes “silent degradation” of the solid-state outputs. Over time, the MOSFETs lose their ability to switch cleanly, leading to “stuck on” or “stuck off” outputs that are difficult to diagnose. My recommendation: Never load a channel beyond 80% of its rated capacity (400 mA max). Use current monitoring devices to track channel loading during operation, and replace modules showing signs of overheating (discolored housing, hot to the touch).

ABB 70AB01b-E

Technical Deep Dive & Overview

The 70AB01b-E is a microprocessor-controlled digital output module designed for ABB’s Procontrol P13 system—the workhorse of power plant automation for over 30 yearsABB Group. It connects to the Procontrol P13 local bus via a 96-pin edge connector, communicating with the main processor module (e.g., 70AA01a-E) to receive output commands and send status feedback.

Internally, the module uses 8 independent solid-state MOSFET output stages, each with its own varistor for inductive load protection. The module’s microprocessor monitors each channel’s current draw and provides diagnostic information to the main processor via the local bus. The 24V DC process supply voltage (UP) powers the output stages, while the module’s logic circuits are powered by the system’s 5V DC bus.

The 70AB01b-E’s design prioritizes reliability in harsh industrial environments. The solid-state outputs eliminate mechanical wear and tear, while the 500V AC isolation protects the module from voltage transients common in power generation applications. The per-channel LEDs provide instant visual confirmation of output status, making it easy to troubleshoot without specialized tools.

In the field, the 70AB01b-E is the “workhorse” of digital control—translating the Procontrol P13 system’s digital commands into physical action in the plant. Its robust design has proven itself in thousands of installations worldwide, operating reliably in temperatures ranging from -25°C in arctic power plants to +60°C in desert refineries. For power plant operators, this module is critical for maintaining safe, efficient operations and avoiding costly unplanned downtime.