Description

Key Technical Specifications

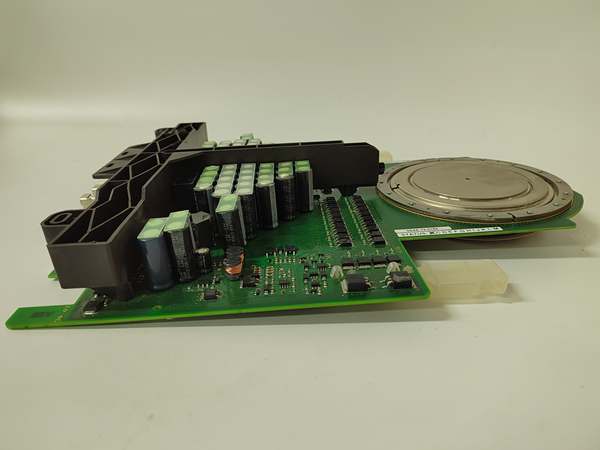

- Model Number: 3BHB030310R0001 5SHY4045L0006

- Manufacturer: ABB Power Semiconductor Division

- Device Type: Asymmetric Integrated Gate-Commutated Thyristor (A-IGCT)

- Blocked Voltage (VDRM): 4500V DC (asymmetric design, 2800V DC link rating)

- Continuous Current (ITGQM): 4000A RMS (junction temp ≤125°C)

- Surge Current (ITSM): 32kA (10ms duration)

- Switching Speed: ≤5μs turn-off; ≤2μs turn-on

- Conduction Loss: 1.40V base drop + 0.325mΩ dynamic resistance

- Cooling Requirement: Forced liquid cooling (50/50 deionized water/glycol), 10-15L/min flow rate

- Gate Driver Compatibility: GVC750BE101 (primary); GVC736CE101 (derated 10%)

- Protection Features: Short-circuit detection (2μs response), overvoltage clamping, overtemperature monitoring, gate signal loss protection

- Operating Temperature: -40°C to +70°C (ambient); -40°C to +125°C (junction)

- Dimensions: 220mm × 140mm × 80mm (91mm frame), 10kg weight

- Certifications: IEC 60747-10, UL 1557, CE

- Compatible Systems: ABB ACS6000 medium-voltage drives, GVC750BE101 gate drivers, 3.3kV-6.6kV industrial/power marine systems

ABB 3BHB030310R0001 5SHY4045L0006

Field Application & Problem Solved

In heavy-duty medium-voltage inverter applications—from 60MW steel rolling mills to offshore floating production storage and offloading (FPSO) vessels—the core challenge is balancing extreme power handling, precise control, and reliability in harsh conditions. Traditional thyristors lack fast switching for tight process control, while IGBTs fail under continuous 4000A loads or suffer excessive energy loss. A Pennsylvania steel mill lost $2.3M/year to IGBT failures, and a Singapore-based FPSO operator struggled with thyristor-driven production pumps that wasted 22% of fuel due to inefficient switching.

This A-IGCT eliminates those trade-offs. You’ll find it in steel hot rolling stands (maintaining ±0.05mm thickness precision), paper machine main drives (±2% web tension control), gas turbine starters (cutting start time from 15min to 5min), and offshore FPSOs—where it powers 25MW production pumps and processing equipment in salt-laden, vibration-prone environments. A recent retrofit on the “卓越” 轮 FPSO replaced aging thyristors with this module, reducing carbon emissions by 8% (1.8MW energy savings) while withstanding 6m wave-induced vibrations.

Its core value is asymmetric design optimization—delivering thyristor-like voltage/current capacity without commutation circuits, IGBT-like switching speed, and 25% lower conduction losses. For industrial users, this translates to 90% fewer semiconductor-related downtime events; for offshore operators, it means 5-year maintenance intervals (double the industry average) and compliance with marine environmental standards.

Installation & Maintenance Pitfalls (Expert Tips)

- Liquid Cooling Water Quality Is Non-Negotiable: Rookies use tap water or low-purity deionized water, causing corrosion and clogging. A Texas power plant’s turbine starter failed after 3 months until we flushed the system and switched to <1μS/cm conductivity water. Fix: Use 50/50 deionized water/ethylene glycol, monitor pH (7.0-9.0), and clean heat exchangers quarterly with 10% citric acid.

- Optical Fiber Handling Breaks Gate Signals: Bending fibers beyond 50mm radius or dirty connectors cause misfiring. An Ohio steel mill’s rolling stand tripped until we replaced a crushed fiber and cleaned connectors with isopropyl alcohol. Fix: Maintain minimum 50mm bend radius, use strain relief, and verify signal strength (-10dBm to -20dBm) with an optical power meter.

- ESD Destroys Modules Instantly: Technicians skipping ESD protocols fry semiconductors. A Colorado mining site lost three modules ($15k each) to static. Fix: Mandate ESD wrist straps (grounded to drive frame), ESD mats, and anti-static packaging for storage/transport—never touch gate terminals or semiconductor surfaces.

- Torque Bolts to Exact Specs: Over-torquing (above 40Nm) warps the cooling interface; under-torquing causes hot spots. A Canada paper mill’s drive overheated until we re-torqued bolts to 35-40Nm with a calibrated wrench. Fix: Use cross-pattern tightening, recheck after 24 hours of operation, and apply ABB-recommended thermal grease (0.1mm thickness).

- Module Static Test Is Non-Skippable: Rushing to commission without static testing misses manufacturing defects. A Michigan plant’s drive shorted on startup due to a hidden gate fault. Fix: Perform 5000V DC insulation test (≥100MΩ), 400A current injection test (conduction drop <1.5V), and gate driver signal verification before energizing the DC link.

Field Fault Troubleshooting (Expert Logic)

While ABB doesn’t publish module-specific fault codes for this IGCT, field experience shows three common failure scenarios—resolved with targeted checks:

- Module Fails to Trigger (No Current Flow): Likely caused by gate driver signal loss or optical fiber damage. Check fiber continuity with an optical power meter, verify GVC750BE101 supply voltage (+15V/-15V), and inspect gate terminal connections for corrosion. A North Sea FPSO had this issue after a storm—saltwater had seeped into the fiber connector, requiring cleaning and waterproofing.

- Overcurrent Trip (Drive Shuts Down): Typically stems from cooling flow loss or module degradation. First, confirm cooling flow rate (10-15L/min) and water temperature difference (<5°C). If cooling is normal, test the module’s conduction voltage drop—values above 1.8V at 400A indicate die degradation, requiring replacement. A Wisconsin paper mill’s trip was traced to a clogged cooling filter, restricting flow to 3L/min.

- Intermittent Misfiring (Fluctuating Motor Speed): Caused by poor grounding or electromagnetic interference (EMI). Ensure the module’s mounting frame is bonded to the drive cabinet ground (resistance <1Ω) and separate power cables from control fibers by at least 30cm. An Indiana steel mill fixed this by rerouting fiber cables away from 480V motor leads.

Installation Post-Calibration 流程 (Field-Proven)

Calibration ensures optimal performance after module replacement—follow these three critical steps:

- Pre-Calibration Preparation: Clean the module’s cooling interface and heat sink, apply fresh thermal grease (0.1mm thickness), and torque bolts to 35-40Nm. Verify cooling system operation (flow rate, water quality) and gate driver compatibility (GVC750BE101 recommended).

- Static Calibration: Use a calibrated DC power supply to inject 10% rated current (400A) into the module. Record conduction voltage drop—must be <1.5V to confirm healthy die. Use an oscilloscope to validate gate signal waveform (±15V, ≥10A peak) and ensure no signal distortion.

- Dynamic Calibration: Run the drive at 25% load for 2 hours, monitoring junction temperature (<100°C) and current balance across parallel modules (variation <5%). Log data via the ACS6000 control panel, compare to baseline values, and adjust gate driver timing if needed. Update the drive’s module configuration to match the new unit’s serial number for fault tracking.

ABB 3BHB030310R0001 5SHY4045L0006

Technical Deep Dive & Overview

The 5SHY4045L0006 is an asymmetric IGCT—engineered for unidirectional current flow in inverters, solving the thyristor/IGBT trade-off. At its core, it uses an asymmetric NPT silicon die: forward blocking (4500V) handles DC link voltage, while limited reverse blocking (1000V) reduces material usage, cutting losses and speeding switching. The integrated gate driver (paired with GVC750BE101) converts optical control signals to ±15V, 10A peak gate pulses—turning the device on in ≤2μs and off in ≤5μs without external commutation circuits.

The module’s liquid cooling manifold routes coolant directly over the semiconductor die, removing up to 100kW of heat—critical for sustaining 4000A continuous current in offshore or high-temperature industrial environments. Built-in protection circuits monitor current, voltage, and temperature, triggering a safe shutdown within 2μs of a fault—preventing catastrophic damage to the drive or motor.

In the ACS6000 drive, multiple modules parallel to handle megawatt-scale loads, synced via the gate driver to maintain current balance. What makes it unique for offshore and marine applications is its robust mechanical design: the 91mm frame features corrosion-resistant coatings, and the cooling system is rated for saltwater-contaminated glycol mixtures (up to 50ppm salt content) without performance degradation.

It’s not just a semiconductor—it’s a purpose-built power switch that delivers the reliability, efficiency, and precision heavy industry and offshore operations demand. Its ability to operate in -40°C to +70°C ambient temperatures, withstand 32kA surge currents, and minimize energy loss makes it irreplaceable in mission-critical drives.