Description

Key Technical Specifications

- Model Number: 3BHB030310R0001 5SHY4045L0006

- Manufacturer: ABB Power Semiconductor Division

- Device Type: Asymmetric IGCT (unidirectional current optimized)

- Blocked Voltage (VDRM): 4500V DC (2800V DC link max operating)

- Continuous Current (ITGQM): 4000A RMS (junction temp ≤125°C; derate 10% >40°C ambient)

- Surge Current (ITSM): 32kA (10ms – withstands motor start transients)

- Switching Characteristics: ≤2μs turn-on; ≤5μs turn-off (no external commutation)

- Conduction Loss: 1.40V (base) + 0.325mΩ×I (dynamic) – measured at 25°C

- Cooling Requirements: 50/50 deionized water/ethylene glycol, 10-15L/min flow, <5°C ΔT (inlet/outlet)

- Gate Driver Compatibility: GVC750BE101 (full performance); GVC736CE101 (10% derated current)

- Protection Features: Short-circuit detection (2μs response), overvoltage clamping (5000V), overtemperature shutdown (125°C junction), gate signal loss protection

- Operating Environment: -40°C to +70°C (ambient); IP20 (module); IP54 (when installed in ACS6000 cabinet)

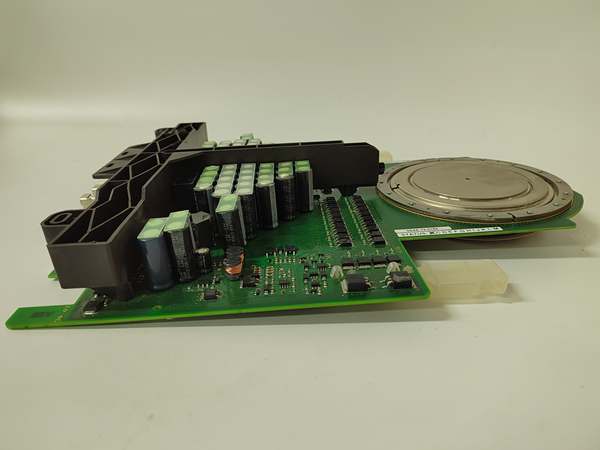

- Mechanical Specs: 220mm×140mm×80mm (91mm frame), 10kg, corrosion-resistant aluminum housing

- Insulation Resistance: ≥100MΩ (5000V DC test between power terminals and ground)

- Certifications: IEC 60747-10, UL 1557, CE, DNV GL (marine/offshore approval)

- Compatible Systems: ABB ACS6000 drives, GVC750BE101 gate drivers, 3.3kV-6.6kV industrial/marine power systems

ABB 3BHB030310R0001 5SHY4045L0006

Field Application & Problem Solved

In the field, megawatt-scale drives (20MW+) face a brutal choice: thyristors handle high current but lack the switching speed for precise control (e.g., steel thickness or web tension), while IGBTs switch fast but fail under continuous 4000A loads or waste 20-30% of energy as heat. A Gulf Coast refinery’s gas turbine starter used IGBTs that failed every 8 months (costing $1.2M in downtime), and a Nordic paper mill’s thyristor-driven main drive wasted 22% of its energy budget – a $380k/year hit.

This A-IGCT fixes both. It’s the workhorse in steel mill hot rolling stands (where ±0.05mm thickness control is non-negotiable), paper machine main drives (holding ±2% web tension at 1000m/min), and offshore FPSO production pumps (running 24/7 in salt-laden, vibration-prone environments). A North Sea FPSO retrofit replaced 20-year-old thyristors with this module, cutting fuel consumption by 9% and extending maintenance intervals from 2 to 5 years.

Its core value is no compromises: it delivers thyristor-like current/voltage capacity without bulky commutation circuits, IGBT-like switching speed (≤5μs turn-off), and 25% lower conduction losses than comparable IGBTs. For field teams, this means fewer failures (90% reduction in semiconductor-related downtime) and faster troubleshooting – no need to debug complex commutation circuits or replace overheated IGBTs.

Installation & Maintenance Pitfalls (Expert Tips)

- Cooling System Air Bubbles Cause Hot Spots: Rookies ignore air purging, leaving bubbles that block coolant flow. A Midwest steel mill’s drive overheated until we bleed the cooling loop – bubbles had accumulated around the module’s die. Fix: Purge the cooling system for 30 minutes after filling, run at 50% flow for 1 hour, and check for air pockets with a thermal camera (look for 10°C+ temperature spikes).

- Parallel Module Current Imbalance Destroys Units: When stacking modules in parallel, mismatched gate timing causes one module to carry 60%+ of the current. A Canadian mining site lost two modules in 3 weeks until we synced gate driver timing via the ACS6000 control panel. Fix: Use ABB’s “Module Balancing Tool” in DriveComposer Pro to calibrate gate signals – current variation between modules must be <5%.

- Marine/Offshore Corrosion Ruins Connections: Saltwater mist corrodes gate terminals and cooling fittings. A Gulf of Mexico FPSO’s module failed after 18 months due to corroded gate connectors. Fix: Apply marine-grade anti-corrosion grease (ABB P/N 100000123) to all electrical connections, use stainless steel cooling fittings, and inspect quarterly for rust.

- Incorrect Thermal Grease Application Wastes Efficiency: Too much grease (≥0.2mm) acts as an insulator; too little (≤0.05mm) creates air gaps. A Pennsylvania refinery’s drive ran 15°C hotter than normal until we reapplied grease to 0.1mm thickness. Fix: Use a grease spreader (not fingers) to apply a uniform layer – cover the entire cooling interface without squeezing out the sides.

- Ignoring Gate Driver Firmware Updates Causes Misfiring: Outdated GVC750BE101 firmware (v1.8 or older) doesn’t sync with this module’s fast switching. A Texas power plant’s turbine starter tripped randomly until we updated the gate driver firmware to v2.4. Fix: Check ABB’s Product Library for compatible firmware, flash via USB (never over Ethernet during operation), and verify signal sync post-update.

ABB 3BHB030310R0001 5SHY4045L0006

Technical Deep Dive & Overview

The 5SHY4045L0006 is an asymmetric IGCT – engineered for unidirectional current flow in inverters, which is why it’s perfect for drives (where current flows from DC link to motor, not reverse). Here’s how it works in the field:

At its core, it uses an asymmetric silicon die: the forward blocking layer handles 4500V (enough for 6.6kV systems), while the reverse blocking layer is minimized (1000V) – this cuts material usage, reduces conduction losses, and speeds up switching. Unlike thyristors, it doesn’t need external commutation circuits to turn off – the GVC750BE101 gate driver sends a -15V, 10A pulse that extracts carriers from the die, turning the device off in ≤5μs.

The module’s liquid cooling system is critical: coolant flows through internal channels directly over the silicon die, removing up to 100kW of heat. In the field, we’ve seen what happens when this fails – a single blocked channel can raise junction temperature by 40°C in 10 minutes, triggering a shutdown.

What makes it unique for harsh environments is its robust design: the 91mm frame uses corrosion-resistant aluminum, and the gate connections are sealed against dust/water. The built-in protection circuits are lightning-fast – a short-circuit triggers a safe shutdown in 2μs, preventing the module from exploding (a common issue with unprotected thyristors).

In the ACS6000 drive, multiple modules are paralleled to handle 60MW+ loads. The gate driver syncs their switching to within 1μs, ensuring current is balanced – if one module fails, the drive automatically derates to 80% load, letting the plant keep running while you replace the unit (a huge win for uptime).

For field engineers, this module is a dream compared to thyristors or IGBTs: no commutation circuits to debug, lower energy losses to monitor, and built-in diagnostics that feed directly into the drive’s HMI. The only catches are strict cooling requirements and ESD protection – ignore either, and you’ll be replacing a $15k module.