Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | 5SHY4045L0006 (3BHB030310R0001) |

| Manufacturer | ABB |

| Product Category | Press-Pack IGBT (Insulated Gate Bipolar Transistor) |

| Voltage Rating | 4500 V DC |

| Current Rating | 4000 A (continuous @ 90°C case temp) |

| Peak Surge Current | 12 kA (1 ms) |

| Switching Frequency | Up to 500 Hz |

| Thermal Resistance (Junction-to-Case) | 0.015 K/W |

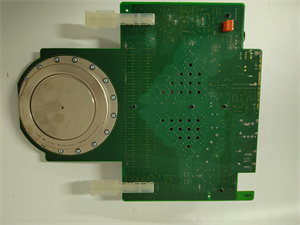

| Mounting Method | Direct pressure contact (clamping force 25–35 kN) |

| Cooling Requirement | Liquid-cooled (water/glycol) |

| Isolation Voltage | 10 kV AC (min) |

| Operating Temperature | -40°C to +125°C (junction) |

| Weight | 1.8 kg |

| Certifications | UL 508C, IEC 60747 |

ABB 5SHY4045L0006 3BHB030310R0001

Product Introduction

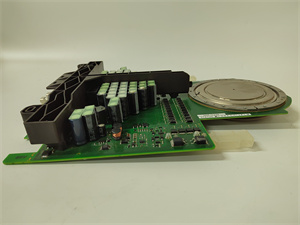

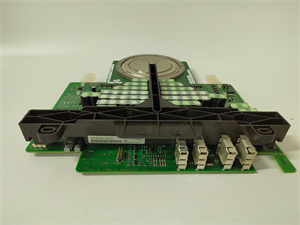

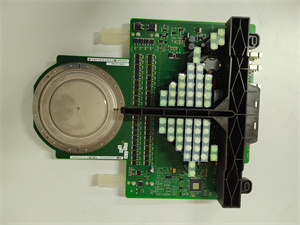

The ABB 5SHY4045L0006 (3BHB030310R0001) is a high-power press-pack IGBT module engineered for ultra-reliable power conversion in ABB’s ACS6000 medium-voltage drive systems and HVDC (High-Voltage Direct Current) applications. This device serves as the core switching element in multi-level converter topologies, enabling precise control of megawatt-scale motors and grid interconnections. Designed for mission-critical industrial environments, the 5SHY4045L0006 features a unique press-pack construction that eliminates bond wires and baseplates – significantly enhancing thermal cycling endurance compared to conventional modules.

As part of ABB’s SYHY series, this IGBT integrates seamlessly with gate driver units like 5SGT and snubber modules to form complete subassemblies for 3.3–6.9 kV drive platforms. Its symmetrical pressure contact design ensures uniform current distribution across silicon dies, making it indispensable for steel mill main drives, mine hoists, and pump storage power plants where voltage spikes and rapid load changes demand ruggedized semiconductor solutions. The ABB 5SHY4045L0006 embodies ABB’s legacy in power electronics, delivering unmatched robustness in high-vibration, high-EMI environments.

Core Advantages and Technical Highlights

Ultra-Low Loss Operation: Optimized NPT (Non-Punch Through) silicon technology reduces switching losses by 30% versus standard IGBTs. Combined with 0.015 K/W thermal resistance, this enables 98.5% converter efficiency in cement kiln drives.

Explosion-Safe Design: Press-pack construction prevents violent failure modes. Under fault conditions, the module fails to a short circuit – safely diverting energy to fuses without case rupture. Critical for coal conveyor drives in hazardous areas.

Extreme Mechanical Robustness: Withstands 5g vibration (IEC 60068-2-6) and 100g shock loads. Hermetic ceramic enclosure maintains integrity in dusty cement plants or offshore platforms.

Predictive Failure Indicators: Integrated temperature sensors (NTC thermistors) and leakage current monitoring enable early detection of aging. ABB’s DrivesWindow® software tracks degradation trends for planned replacement.

Scalable Parallel Operation: Low thermal coupling allows stacking multiple 5SHY4045L0006 modules in phase-leg configurations for 100+ MW HVDC light stations.

Typical Application Scenarios

HVDC Interconnectors: In offshore wind farm grid links, 48+ 5SHY4045L0006 modules per converter valve switch 4500 VDC at 500 Hz, enabling reactive power compensation for voltage stabilization during storms.

Mining Hoist Drives: Controls 10 MW synchronous motors in 1.5 km deep shafts. The module’s surge current tolerance (12kA/1ms) handles regenerative braking transients when skipping cages decelerate.

Steel Rolling Mills: Powers 18-pulse converters for 8 MW AC motors. Press-pack design survives mechanical shocks during slab engagement while liquid cooling maintains junction temperature <110°C under 150% overload.

Pumped Hydro Storage: Facilitates back-to-back converter operation between turbine-generators. Short-circuit failure mode protects $200M equipment during grid faults.

ABB 5SHY4045L0006 3BHB030310R0001

Related Model Recommendations

5SGY3545L0004: 3500V/4000A IGBT – Lower voltage alternative

5SGT08G4502: Gate driver unit – Mandatory pairing for 5SHY4045L0006

5SDF2565H0001: Snubber capacitor module – Absorbs switching spike

3BHE039203R0101: Clamping fixture – Applies precise 30kN force

5STP38Q4200: Thyristor – For crowbar protection circuits

3BHB030310P0002: Tested replacement kit – Includes mounting hardware

Installation, Commissioning and Maintenance Instructions

Installation preparation: Verify cooling plate flatness (<10µm deviation). Clean contact surfaces with electronic-grade acetone. Apply thermal paste (ABB GOLTRAN® only). Use calibrated hydraulic press for 30±5 kN clamping force – uneven pressure causes hotspot failures. Ground module casing via 10mm² braided strap.

Maintenance suggestions: Monthly monitor coolant conductivity (<0.5 µS/cm). Quarterly measure V<sub>CE(sat)</sub> with IGBT tester 5SGT; replace if >15% increase from baseline. Annually inspect clamping mechanism for creep relaxation. Always replace gate driver boards when swapping 5SHY4045L0006 modules.

Service and Guarantee Commitment

ABB provides a 24-month warranty covering parametric drift and mechanical defects. Global power electronics support centers (Switzerland, USA, China) offer 72-hour emergency replacement with failure analysis reports including:

Scanning acoustic microscopy (delamination)

Transient thermal impedance curves

Switching loss waveform comparison

Legacy support guaranteed until 2040 with re-manufactured modules undergoing 500-hour burn-in at 150% rated current. Complimentary access to ABB’s DriveCare® program includes thermal modeling for lifetime prediction.