Description

Key Technical Specifications

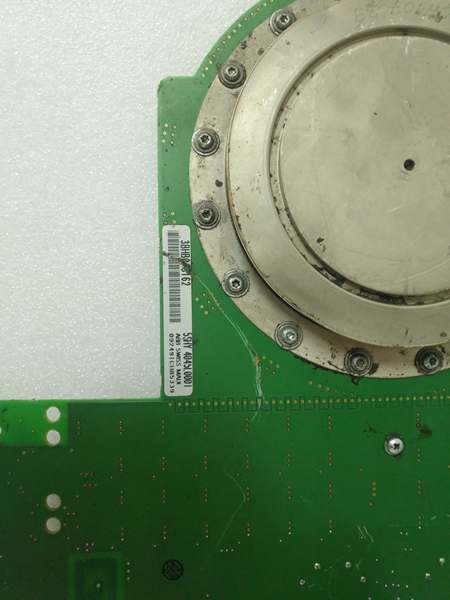

- Model Number: 5SHY4045L0001

- Manufacturer: ABB

- Device Type: Integrated Gate-Commutated Thyristor (IGCT)

- Voltage Rating: 4500V DC (continuous operating)

- Current Rating: 4000A (rms continuous)

- Conduction Losses: Low-profile semiconductor design for minimal energy waste

- Switching Speed: Rapid commutation for precise power control

- Operating Temperature: -25°C to +70°C (-13°F to +158°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Isolation: Reinforced insulation for high-voltage environments

- Humidity Tolerance: 5% to 95% RH (non-condensing)

- Protection Class: IP20 (when mounted in approved enclosures)

- Dimensions (W x H x D): 40mm x 25mm x 20mm

- Weight: Approx. 0.1 kg

- Compliance: Meets IEC 60947-5-1 standards

- Diagnostic Features: Built-in operational parameter monitoring

- Mounting: Compatible with ABB converter valve assemblies and standard heatsinks

ABB 5SHY4045L0001

Field Application & Problem Solved

In high-power industrial and energy systems—HVDC transmission networks, steel mill drives, and large-scale wind/solar farms—the greatest challenge is converting and controlling massive electrical loads without sacrificing efficiency or reliability. Traditional thyristors or IGBTs struggle with the extreme voltage/current demands of these applications, suffering from high conduction losses, slow switching speeds, or premature failure under continuous heavy duty. This IGCT module solves that by combining robust semiconductor design with high-power handling capabilities, delivering precise control even in the most demanding environments.

You’ll typically find this module as a core component in HVDC converter valves, where it enables efficient long-distance electricity transmission with minimal energy loss—critical for connecting regional power grids or integrating remote renewable energy sources. It’s also a workhorse in heavy industries: powering large motors in steel manufacturing, mining equipment, and pulp mills, where precise speed and torque control directly impact production efficiency. In wind and solar farms, the module acts as a key part of the power conversion system, converting variable renewable energy into stable grid-compatible power.

Its core value lies in balancing performance and durability. The 4500V/4000A rating handles ultra-large power loads that would overwhelm standard modules, while low conduction losses reduce energy waste and operational costs. The built-in diagnostics are a game-changer in the field: real-time monitoring of operational parameters allows technicians to identify potential issues before they cause catastrophic failures, minimizing unplanned downtime. For plant operators and grid managers, this translates to more reliable power delivery, lower maintenance costs, and the ability to scale renewable energy integration—addressing both operational and sustainability goals.

Installation & Maintenance Pitfalls (Expert Tips)

Heatsink Mounting Torque Is Critical

Rookies often over-tighten or under-tighten the module to the heatsink. Too loose, and poor thermal transfer causes the IGCT to overheat and trip. Too tight, and you’ll crack the semiconductor substrate—an invisible damage that leads to failure under load. Follow ABB’s spec: 4–6 Nm torque for mounting bolts. Use a calibrated torque wrench and apply thermal grease evenly (1mm thickness) between the module and heatsink to ensure optimal heat dissipation.

Ignore Humidity Limits at Your Peril

While the module tolerates 5–95% RH, condensation is its worst enemy. Installing it in unconditioned enclosures (common in remote wind farms or outdoor HVDC stations) leads to moisture buildup on terminals, causing corrosion and short circuits. Use dehumidifiers in enclosures or apply a conformal coating to the module’s terminals if outdoor mounting is unavoidable. Check for white/green corrosion during routine maintenance—this is a red flag for imminent failure.

Skipping Pre-Installation Continuity Checks

Never mount the module without verifying continuity across the IGCT terminals. Shipping damage or static discharge can damage the semiconductor junction, creating an open or short circuit that won’t be detected until power-up. Use a multimeter set to the diode test function to check for proper junction behavior—any deviation from ABB’s specified values means the module is faulty and should be replaced.

Misaligning Control Signal Wiring

The module’s gate control signals are sensitive to noise and miswiring. Rookies often run control cables parallel to high-voltage power cables, introducing electromagnetic interference (EMI) that causes erratic switching. Maintain at least 30cm (12 inches) of separation between control and power cables, and use shielded twisted-pair cables for gate signals. Ground the shield at one end (preferably the control cabinet side) to minimize noise pickup. Also, verify that gate voltage and current match ABB’s specifications—overdriving the gate will burn out the control circuit.

ABB 5SHY4045L0001

Technical Deep Dive & Overview

The ABB 5SHY4045L0001 is a high-performance Integrated Gate-Commutated Thyristor (IGCT) module, part of ABB’s renowned 5SHY series of power semiconductors. It’s engineered to bridge the gap between high-voltage power handling and precise control, serving as a critical component in power conversion systems that demand both reliability and efficiency.

At its core, the module uses an IGCT semiconductor design—a hybrid between a thyristor and a gate-turn-off (GTO) thyristor—combining the high current/voltage capabilities of a thyristor with the fast switching speed of a GTO. This allows it to handle 4500V and 4000A while maintaining low conduction losses, a key advantage in applications where energy efficiency is paramount. The module communicates with the system controller via low-voltage gate control signals, which trigger the IGCT to switch on or off with rapid commutation, enabling precise regulation of power flow.

The modular design facilitates seamless integration with ABB’s converter valve assemblies and other power system components, simplifying both new installations and retrofits. Internally, the module incorporates reinforced insulation to protect against voltage transients common in high-power environments, while the compact form factor (40mm x 25mm x 20mm) allows dense packaging in converter cabinets—critical for space-constrained applications like wind turbine nacelles.

Built-in diagnostic features monitor key operational parameters (temperature, current, voltage) and send real-time data to the system controller. This allows for proactive maintenance, as technicians can address issues like rising temperatures or irregular current draw before they lead to module failure. The rugged construction—rated for -25°C to +70°C operating temperatures and 5–95% humidity—ensures reliable performance in harsh industrial and outdoor environments. Overall, this module is a testament to ABB’s expertise in high-power semiconductors: a durable, efficient, and precise solution designed for the most demanding power conversion challenges.