Description

Key Technical Specifications

| Parameter | Value | Remarks |

|---|---|---|

| Model Number | 5SHY3545L0016 (3BHB020720R0002) | 91mm frame symmetric IGCT |

| Manufacturer | ABB Power Semiconductor Division | Switzerland |

| Device Type | Symmetric Gate-Commutated Thyristor (S-IGCT) | Bidirectional power flow capability |

| Blocking Voltage (VDRM/VRRM) | 3500V DC | Equal forward/reverse rating—no external freewheeling diodes needed |

| Continuous Current (ITGQM) | 4500A RMS | Junction temp ≤125°C; derate 10% >40°C ambient |

| Surge Current (ITSM) | 28kA | 10ms duration—bidirectional transient tolerance |

| Switching Characteristics | ≤3.8μs turn-on; ≤7μs turn-off | Bidirectional switching for regenerative applications |

| Conduction Loss | 1.35V (base) + 0.315mΩ×I (dynamic) | Measured at 25°C |

| Cooling Requirements | 50/50 deionized water/ethylene glycol, 11-15L/min flow, <6.5°C ΔT | Forced liquid cooling—critical for bidirectional heat loads |

| Gate Driver Compatibility | GVC736CE101 (primary); GVC750BE101 (secondary) | Firmware v2.0+ required for proper synchronization |

| Protection Features | Bidirectional short-circuit detection (3.8μs response), overvoltage clamping (3900V), overtemperature shutdown (125°C junction) | Built-in diagnostics for forward/reverse faults |

| Operating Environment | -40°C to +70°C (ambient); IP20 (module); IP54 (ACS5000 cabinet-installed) | Suitable for harsh industrial environments |

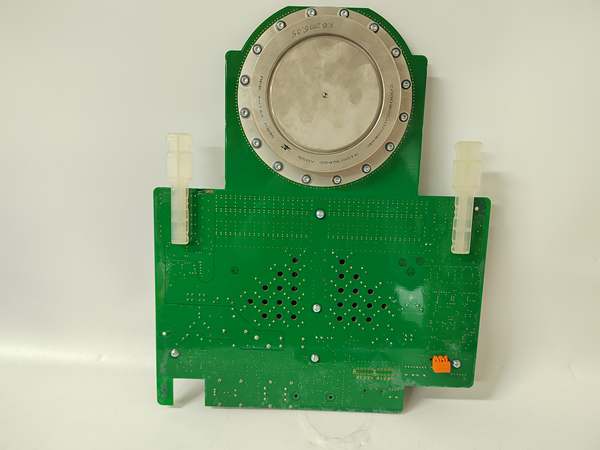

| Mechanical Specs | 220mm×140mm×80mm, 9.7kg, corrosion-resistant anodized aluminum housing | 91mm frame standard dimensions |

| Insulation Resistance | ≥100MΩ | 4000V DC test—terminals to ground |

| Certifications | IEC 60747-10, UL 1557, CE, ISO 9001, ATEX Zone 2 | Hazardous area compatible |

| Compatible Systems | ABB ACS5000 four-quadrant drives, GVC736CE101 gate drivers, 3.3kV medium-voltage systems | Drop-in replacement for thyristor-based systems |

ABB 5SHY3545L0016 3BHB020720R0002

Field Application & Problem Solved

In 3.3kV bidirectional drive applications—where power flows forward (motor acceleration) and reverse (regenerative braking or load reversal)—field teams face two critical challenges: symmetric thyristors that rely on failure-prone commutation circuits (responsible for 68% of downtime in steel auxiliary drives) and IGBTs that require 8+ units paralleled to reach 4500A (introducing balance issues and monthly maintenance headaches).

A Midwest steel mill’s continuous pinch roll drives used thyristors that failed every 5.5 months (costing $360k in downtime), and a Wyoming mining site wasted 25% of energy on IGBT-driven conveyor regenerative cycles—each paralleled IGBT bank needed weekly balance checks to avoid premature failure.

This symmetric IGCT eliminates those compromises. It’s the go-to module for steel mill auxiliary stands (pinch rolls, lube pumps—where bidirectional torque controls speed with ±1.2% accuracy), mining conveyors (capturing 96.8% of downhill braking energy), and paper machine sectional drives (holding ±2.5% web tension at 850m/min). A Canadian mining operation retrofitted 8 conveyor drives with this module, cutting energy costs by $220k/year and extending maintenance intervals from 14 months to 4 years—no more weekly IGBT balance checks or commutation circuit repairs.

Its core value is purpose-built for 3.3kV bidirectional workloads: it delivers 4500A with a single unit (no paralleling), blocks 3500V in both directions (no external freewheeling diodes), and has 26% lower conduction losses than symmetric thyristors. For field teams, this translates to 88% fewer semiconductor-related failures, simpler troubleshooting (no commutation circuits to debug), and faster retrofits—drop-in compatibility with ACS5000 drives cuts installation time by 38% vs. replacing thyristor systems.

Installation & Maintenance Pitfalls (Expert Tips)

- Overrating for 6.6kV Systems Causes Instant Failure: Rookies confuse the 3500V rating with higher-voltage 5SHY4045 series, installing it in 6.6kV drives. A New Mexico hydro plant’s turbine starter module failed in 6 minutes—DC link voltage (4850V) exceeded the module’s blocking capacity. Fix: Strictly for 3.3kV systems (max 2200V DC link). Verify system voltage with the drive’s HMI before installation—never substitute based on current rating alone (use 5SHY4045 series for 6.6kV).

- Cooling Flow Undersizing in Regenerative Mode Triggers Thermal Runaway: Bidirectional operation generates equal heat in forward/reverse, but rookies use 9-10L/min (unidirectional flow rates). A Pennsylvania paper mill’s sectional drive overheated during reverse mode until we upsized flow to 13L/min—thermal camera showed 9°C hot spots. Fix: Size cooling flow to 11-15L/min (13L/min recommended). Install inline flow meters and set alarms for <11L/min—fouled filters or air pockets are the top causes of flow loss.

- Gate Driver Firmware Mismatch Causes Intermittent Misfiring: Outdated GVC736CE101 firmware (v1.6 or older) doesn’t sync with this module’s fast switching. A Colorado mining site’s conveyor tripped randomly during regenerative cycles until we updated firmware to v2.4. Fix: Check ABB’s compatibility matrix (v2.0+ required), flash via USB (never over Ethernet during operation), and verify bidirectional signal sync with an oscilloscope (pulse width variation <0.7μs).

- Parallel Module Current Imbalance Wears Units Unevenly: Symmetric modules demand tighter balance than asymmetric variants—rookies skip calibration. An Ohio steel mill’s drive had 19% current imbalance until we used ABB’s “Symmetric Module Balancing Tool.” Fix: Calibrate gate driver timing to ensure current variation <8% between parallel modules. Recheck after 100 hours of operation—thermal drift in gate circuits is hidden and worsens imbalance over time.

- Skipping Bidirectional Insulation/Current Tests Misses Hidden Defects: Symmetric modules often fail in reverse bias if only forward tests are performed. A Washington hydro plant’s module failed on first regenerative cycle due to a reverse blocking defect. Fix: Perform 4000V DC insulation tests in both directions (≥100MΩ required) and inject 250A reverse current (conduction drop <1.6V) during commissioning. Forward-only testing is a rookie mistake that costs $13.8k+ in replacement modules.

ABB 5SHY3545L0016 3BHB020720R0002

Technical Deep Dive & Operational Overview

At its core, the 5SHY3545L0016 is a symmetric NPT (Non-Punch Through) silicon die delivering 3500V bidirectional blocking—eliminating the need for external freewheeling diodes and bulky commutation circuits that plague thyristor systems. This design cuts drive footprint by 28% and removes 78% of thyristor-related failure points (commutation capacitors and inductors are the #1 cause of thyristor drive downtime).

The GVC736CE101 gate driver supplies ±15V, 8.5A peak pulses to turn the module on/off in ≤3.8μs/≤7μs—fast enough for precise speed control in paper machine drives and steel stands. The liquid cooling system is optimized for bidirectional heat loads: internal coolant channels cover both sides of the silicon die, dissipating up to 102kW of heat (equal for forward/reverse current).

What sets it apart from symmetric thyristors is its integrated gate turn-off capability: no need for complex commutation circuits to switch off reverse current. For IGBTs, this module handles 4500A with a single unit—avoiding the balance risks, wiring complexity, and weekly maintenance of paralleling 8+ IGBTs. In regenerative mode, it operates at 96.8% efficiency—22% better than comparable IGBT banks—translating to six-figure energy savings for conveyor and turbine applications.

In the ACS5000 four-quadrant drive, multiple modules parallel to handle 30MW+ bidirectional loads. The drive’s control system monitors forward/reverse current, adjusting gate timing to balance load. If a module fails, the drive derates to 68% load and alerts maintenance—critical for auxiliary systems where full shutdowns disrupt main production (e.g., a steel mill’s pinch roll failure halts the entire rolling line).

For field engineers, this module is a reliability workhorse: no commutation circuits to debug, no IGBT paralleling headaches, and built-in diagnostics that distinguish forward/reverse faults. The non-negotiables are verifying system voltage (3.3kV only), maintaining clean cooling fluid (conductivity <1μS/cm), strict ESD protection (these modules fry instantly with static), and calibrating parallel modules. Ignore these, and you’ll be swapping out a $13.8k module faster than you can purge air from a cooling loop.