Description

Key Technical Specifications

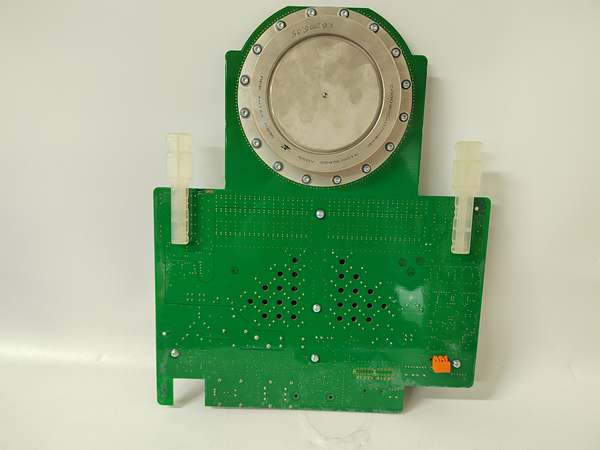

- Model Number: 5SHY3545L0016

- Manufacturer: ABB

- Device Type: Integrated Gate-Commutated Thyristor (IGCT)

- Blocking Voltage: 4500V DC (continuous operating)

- Surge Current Rating: 30kA (peak)

- Continuous Current Rating: 3500A (rms, typical for 5SHY series sizing)

- Switching Frequency: 2kHz – 10kHz (optimized for medium-voltage drives)

- Junction Temperature: -40°C to +150°C (-40°F to +302°F)

- Storage Temperature: -40°C to +175°C (-40°F to +347°F)

- Isolation: Reinforced high-voltage insulation (compliant with IEC standards)

- Cooling Interface: Water-cooled connection (standard for high-power dissipation)

- Control Interface: Integrated gate drive with low-voltage signal input

- Dimensions (W x H x D): 176mm x 64mm x 40mm

- Weight: Approx. 0.25kg

- Protection Features: Over-temperature monitoring, over-current detection

- Compliance: Meets IEC 60947-5-1 and industrial power semiconductor standards

- Indicator Lights: Status LED, over-temperature alert LED

- Mounting: Compatible with ABB medium-voltage drive assemblies and standard heatsinks

ABB 5SHY3545L0016

Field Application & Problem Solved

In medium-voltage industrial environments—steel mills, mining operations, large pulp mills, and heavy-duty conveyor systems—the biggest challenge is delivering precise, reliable power to massive motors and drives without catastrophic failure. Traditional power semiconductors either lack the voltage/current capacity to handle these loads or suffer from slow switching speeds, leading to inefficient power conversion, overheating, and unplanned downtime. This IGCT module solves that by combining robust high-power handling with integrated gate drive technology, bridging the gap between raw power and precise control.

You’ll typically find this module at the core of medium-voltage drives powering 1MW+ motors—think steel mill rolling stands, mine hoists, or pulp mill digester agitators. It’s also critical in grid-connected power conversion systems, such as those used in large-scale renewable energy plants or industrial backup generators, where stable power flow and surge protection are non-negotiable. In retrofits, it’s a go-to replacement for aging thyristor modules, as its 4500V blocking voltage and 30kA surge rating handle the transient loads that often take down older components.

Its core value is resilience paired with efficiency. The 30kA surge current rating acts as a safety net for the system, absorbing sudden current spikes from motor startups or grid fluctuations that would destroy lesser modules. The integrated gate drive eliminates compatibility issues common with external drives, simplifying installation and reducing failure points. For plant operators, this translates to fewer unplanned outages—critical in industries where downtime costs tens of thousands per hour. The optimized switching frequency (2kHz–10kHz) balances power control precision with low conduction losses, cutting energy costs while extending the module’s lifespan.

Installation & Maintenance Pitfalls (Expert Tips)

Water-Cooling Flow Rate Is Non-Negotiable

Rookies often under-size the cooling system or ignore flow rate specs. This module relies on water cooling to dissipate high power losses—insufficient flow (below ABB’s recommended 5L/min) causes junction temperatures to spike, triggering over-temperature trips or permanent semiconductor damage. Install a flow meter in the cooling loop and verify flow rate before power-up. Also, use deionized water with the recommended corrosion inhibitor—tap water causes scale buildup in cooling channels, reducing efficiency over time.

Gate Drive Wiring: Noise Kills Precision

The integrated gate drive is sensitive to electromagnetic interference (EMI) from high-voltage power cables. Running control wires parallel to power cables (a common shortcut) introduces noise that distorts switching signals, leading to erratic drive performance or false fault triggers. Maintain at least 30cm (12 inches) of separation between control and power cables, and use shielded twisted-pair wiring for gate signals. Ground the shield at the control cabinet end only—double-ended grounding creates ground loops that amplify noise.

Torque Control Prevents Substrate Cracking

Mounting the module to heatsinks or drive assemblies with incorrect torque is a silent killer. Over-tightening (exceeding 6Nm) cracks the ceramic semiconductor substrate, while under-tightening (below 4Nm) creates air gaps that block heat transfer. Use a calibrated torque wrench and follow ABB’s spec: 4–6Nm for mounting bolts. Apply a thin, even layer (1mm) of thermal compound between the module and heatsink—skipping this step or using too much compound traps air and increases thermal resistance.

Pre-Installation Surge Test Saves Headaches

Never install a new or refurbished module without verifying surge current handling. Shipping damage or static discharge can weaken the semiconductor junction, leaving it unable to withstand 30kA surges. Use a specialized surge tester to simulate peak current loads—any deviation from ABB’s response curves means the module is compromised. Also, check the over-temperature LED circuit with a multimeter—faulty indicators lead to missed warnings and catastrophic failure in the field.

ABB 5SHY3545L0016

Technical Deep Dive & Overview

The ABB 5SHY3545L0016 is a high-performance IGCT module engineered for the most demanding medium-voltage power conversion applications. It builds on ABB’s 5SHY series legacy, combining the ruggedness of thyristors with the switching precision of modern power semiconductors to deliver reliable performance in heavy-industry environments.

At its core, the module uses an IGCT semiconductor architecture—designed to handle high blocking voltages (4500V) and surge currents (30kA) while maintaining fast switching speeds (2kHz–10kHz). The integrated gate drive is a key differentiator: unlike discrete gate drives, it’s matched to the IGCT’s characteristics, reducing switching losses and eliminating compatibility issues. This integration also simplifies wiring and reduces the module’s footprint, critical for space-constrained medium-voltage drive cabinets.

The module’s thermal design is optimized for water cooling, with a dedicated interface that efficiently transfers heat from the semiconductor junction to the cooling loop. This allows it to operate at junction temperatures up to 150°C without de-rating, a critical advantage in hot industrial environments. Internally, over-temperature and over-current protection circuits monitor operational parameters in real time, sending alerts via the status LEDs and control interface to prevent permanent damage.

Ruggedness is built into every component: the module’s reinforced insulation protects against voltage transients common in medium-voltage systems, while the wide storage temperature range (-40°C to +175°C) ensures reliability during shipping and storage in extreme climates. The compact dimensions (176mm x 64mm x 40mm) and lightweight design (0.25kg) facilitate handling and installation, even in large drive assemblies with multiple modules. Overall, this module is a workhorse—engineered to deliver precise, efficient power control while withstanding the abuse of heavy industry, making it a staple for plant operators who prioritize uptime and performance.