Description

Key Technical Specifications

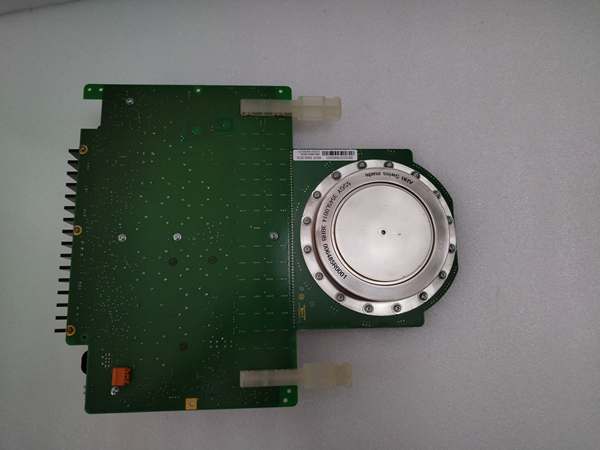

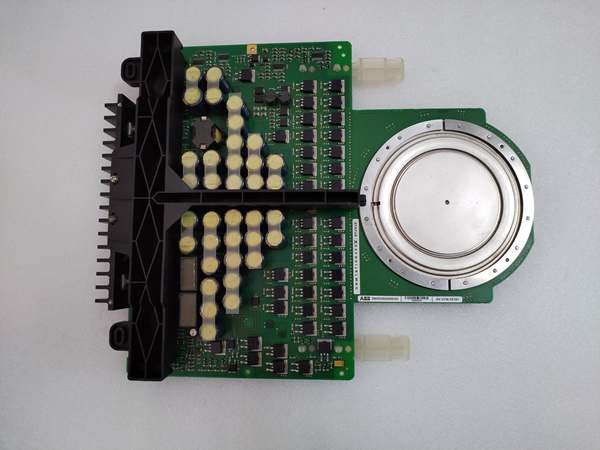

- Model Number: 5SHY3545L0014

- Manufacturer: ABB

- Device Type: Integrated Gate Commutated Thyristor (IGCT) Module

- Rated DC Charging Voltage: 4.4 kV

- Peak Voltage: 9.0 kV

- Rated Turn-off Current: 1850 A

- Operating Temperature Range: -40℃ to +70℃

- Dimensions: 240 mm x 180 mm x 60 mm

- Weight: 2.6 kg

- Safety Certifications: SIL 3, CE, UL, FM, CSA

- Fault Tolerance Architecture: Triple Modular Redundancy (TMR)

- Mechanical Design: Hot-swappable configuration

- Integration Feature: Integrated dedicated gate drive circuit

ABB 5SHY3545L0014

Field Application & Problem Solved

In high-power industrial environments, the biggest challenge is balancing fast switching speeds with low conduction losses—traditional thyristors lack switching agility, while IGBTs struggle with the extreme voltage and current demands of megawatt-scale systems. This gap often leads to inefficient power conversion, unplanned downtime, and excessive energy waste in critical infrastructure. The 5SHY3545L0014 solves this by merging the low conduction losses of thyristors with the fast switching performance of IGBTs, creating a reliable middle ground for high-voltage applications.

You will typically find this module in wind and solar farms, where it converts variable renewable energy into stable power suitable for grid integration. It’s also a staple in medium-voltage industrial drives for paper mills and refineries, and in HVDC transmission systems that move bulk power over long distances. In 轨道交通 (rail transit) applications, it regulates power for high-speed trains, where consistent performance under vibration and temperature fluctuations is non-negotiable.

Its core value lies in preventing costly system failures and optimizing energy efficiency. The TMR architecture eliminates single points of failure by cross-verifying signals across three independent channels—critical in wind farms where a module outage could halt an entire turbine array. For HVDC operators, its high voltage and current ratings cut down on the number of modules needed per system, reducing installation complexity and maintenance overhead. In industrial settings, the hot-swappable design means maintenance can be done without shutting down the entire production line, preserving productivity.

Installation & Maintenance Pitfalls (Expert Tips)

- Ignoring Gate Voltage Calibration: Rookies often skip verifying the ±15V gate voltage requirement during installation. Mismatched gate voltage doesn’t just reduce switching precision—it can burn out the integrated gate drive circuit. Always use a calibrated multimeter to confirm gate voltage matches the module’s specs before powering up; this prevents irreversible damage in the first 10 minutes of operation, a common field failure point.

- Poor Thermal Management During Mounting: The module generates significant heat during high-current switching, but new technicians frequently mount it without checking heatsink compatibility. The 5SHY3545L0014 relies on efficient heat dissipation to maintain its -40℃ to +70℃ operating range. Use only ABB-approved heatsinks, and ensure thermal paste is evenly applied—air gaps here cause localized overheating, which degrades the silicon components and shortens lifespan by 50% or more in harsh refinery or power plant environments.

- Neglecting TMR Channel Synchronization: The triple modular redundancy feature only works if all three channels are synchronized. Technicians often assume synchronization is automatic, but wiring discrepancies can throw channels out of alignment. After installation, run a TMR diagnostic via the control system to confirm signal consistency. Unsynchronized channels lead to false fault alerts or, worse, failure to detect real issues—we’ve seen this cause unnecessary shutdowns in solar farms during peak energy production.

- Rushing Hot-Swap Procedures: The hot-swappable design is meant to minimize downtime, but rookies rush the process without isolating the module’s power branch. Always de-energize the specific circuit branch, not just the control system, before swapping. Skipping this step creates arc flashes that damage the module’s connection terminals, leading to intermittent power loss in subsequent operation.

ABB 5SHY3545L0014

Technical Deep Dive & Overview

The 5SHY3545L0014 is a purpose-built IGCT module that bridges the gap between traditional thyristors and modern IGBTs for high-power applications. At its core, it integrates a gate-commutated thyristor (GCT) with a dedicated gate drive circuit, which enables precise control over the switching of massive electrical loads—critical for applications where even microsecond delays can cause system instability. The module’s design leverages advanced silicon technology to achieve a 1850A turn-off current and 9.0kV peak voltage, making it capable of handling megawatt-scale power flows without compromising efficiency.

Its triple modular redundancy (TMR) architecture is a standout technical feature: three independent signal channels continuously cross-check data, instantly flagging or compensating for faults. This is paired with built-in protection circuitry that guards against overloads, voltage spikes, and thermal runaway—common hazards in renewable energy and transmission environments. The module communicates with central control systems via its integrated interface, relaying real-time data on temperature, current, and voltage to enable predictive maintenance.

Physically, its compact form factor (240x180x60mm) allows for dense packing in control cabinets, which is essential in space-constrained areas like offshore wind turbines or substation control rooms. The hot-swappable design is engineered to address the reality of industrial maintenance—instead of shutting down an entire HVDC converter station or factory drive system, technicians can replace the module in minutes, drastically reducing downtime. Overall, it operates as a reliable, precise linchpin in power systems where stability, efficiency, and fault tolerance are non-negotiable.