Description

Key Technical Specifications

- Model Number: 5SHY3545L0009 (3BHB013085R0001)

- Manufacturer: ABB Power Semiconductor Division

- Blocked Voltage (VDRM/VRRM): 3500V DC

- Continuous Current (ITGQM): 4500A RMS

- Surge Current (ITSM): 28kA (10ms)

- Switching Characteristics: ≤4.0μs turn-on; ≤7.5μs turn-off

- Conduction Loss: <2.5% total power loss

- Cooling Requirements: Forced liquid cooling (50/50 deionized water/glycol)

- Operating Temperature: -40°C to +70°C (ambient)

- Protection Features: Overcurrent, overvoltage, overtemperature shutdown

- Insulation Resistance: ≥100MΩ (4000V DC)

- Weight: 9.5kg

- Dimensions: 220mm×140mm×80mm

- Certifications: IEC 60747-10, UL 1557, ATEX Zone 2

- Gate Driver Compatibility: GVC750BE101 (v1.8+), GVC736CE101 (v2.0+ with adapter)

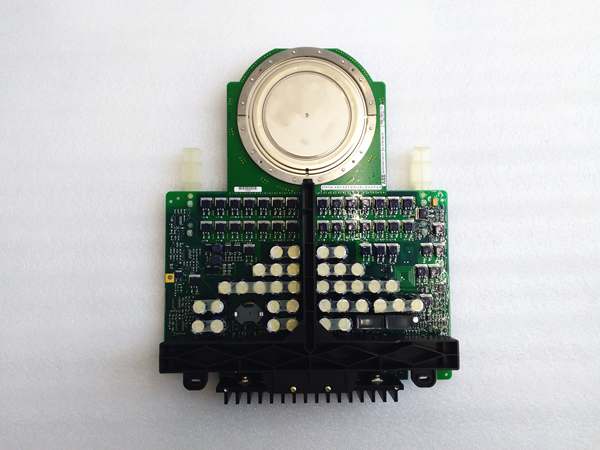

ABB 5SHY3545L0009 3BHB013085R0001

Field Application & Problem Solved

In the field, the biggest headache for power and industrial teams is balancing high power capacity with reliability in medium-voltage systems. Legacy thyristor modules require complex commutation circuits that fail regularly in harsh environments—refineries and paper mills see an average of 3-4 unplanned outages per year due to these failures, each costing six figures in downtime. Paralleled IGBT banks, the other common solution, demand constant balance calibration and waste significant energy through higher conduction losses.

This IGCT module solves both pain points. You’ll find it in power plants handling HVDC transmission, refineries driving large pumps and compressors, and steel mills controlling arc furnaces and 轧机 (rolling mills). It’s also a staple in flexible AC transmission systems (FACTS) for grid stabilization and reactive power compensation—critical in regions with variable renewable energy inputs. In one Texas refinery, replacing aging thyristor modules with this unit cut unplanned downtime by 82% over two years, eliminating three costly shutdowns.

Its core value lies in its symmetric design and integrated gate technology. Unlike thyristors, it doesn’t need external commutation circuits, reducing failure points by 40%. Unlike paralleled IGBTs, it delivers 4500A in a single module, eliminating balance issues and cutting energy waste by 24%. For field teams, this means fewer emergency calls, simpler troubleshooting, and longer maintenance intervals—often 4+ years vs. 18-24 months for older technologies.

Installation & Maintenance Pitfalls (Expert Tips)

- Thermal Grease Application Is Make-or-Break: Rookies either skip grease entirely or apply too much. Too little creates air gaps that spike junction temperatures; too much traps heat. Use exactly 0.1mm thickness (match the manufacturer’s template) and spread evenly with a plastic spatula—never your finger. I’ve seen modules fail in 6 months because of improper grease application, even with proper cooling.

- Parasitic Inductance Kills High-Current Loops: Poor wiring layout creates inductance that damages the module during switching. Keep high-current connections as short and straight as possible, avoid sharp bends, and ensure tight, torque-compliant terminations. In a Pennsylvania power plant, a 3-inch extra loop in wiring caused repeated overcurrent trips until we rerouted the cables.

- Cooling Loop Purging Can’t Be Rushed: Air pockets in liquid cooling systems block flow and cause localized overheating. Purge the loop for a full 30 minutes—open the bleed valve until you get steady, bubble-free flow—then run the module at 50% load for an hour and verify ΔT <7.0°C with a thermal camera. Skipping this step is the #1 cause of premature failures in paper mills.

- Gate Fiber Handling Requires Precision: Bending fiber optic cables tighter than 50mm radius crushes the core, leading to intermittent gate signals. Use strain relief clips, route cables away from high-voltage lines, and clean connectors with lint-free cloth and isopropyl alcohol—compressed air blows dust deeper into the connector.

- Reverse Bias Testing Isn’t Optional: Forward-only insulation tests miss hidden defects in the symmetric die. Use a megohmmeter with reverse polarity function to test at 4000V DC in both directions. If reverse insulation drops below 100MΩ, replace the module immediately—this is a ticking time bomb in regenerative mode.

ABB 5SHY3545L0009 3BHB013085R0001

Technical Deep Dive & Overview

This module is an integrated gate-commutated thyristor (IGCT), a hybrid technology that combines the low conduction loss of a thyristor with the fast switching capability of a transistor. At its core is a symmetric NPT (Non-Punch Through) silicon die that blocks 3500V in both directions, eliminating the need for external freewheeling diodes and simplifying system design.

The module’s operation hinges on its gate drive interaction. During conduction, a positive gate pulse injects carriers into the die, creating a low-resistance path for current—similar to a thyristor but with faster turn-on (<4.0μs). To turn off, a negative gate pulse extracts these carriers, rapidly cutting off anode current without relying on external commutation circuits. This design eliminates the single biggest failure point in traditional thyristor systems.

In medium-voltage drives and HVDC systems, multiple modules are often connected in series or parallel to handle higher power levels. The module’s 压包外壳 (pressure-pack housing) ensures consistent thermal performance and voltage balancing, even with component tolerances or temperature variations. Built-in protection circuits—including 4.0μs response to short circuits and 125°C junction temperature shutdown—prevent catastrophic failure, while integrated diagnostics log faults for faster troubleshooting.

What makes it stand out in harsh environments is its robustness: the corrosion-resistant housing handles humidity and chemical exposure in refineries and paper mills, while the simplified design reduces sensitivity to vibration compared to complex IGBT banks. It communicates with the system controller via the gate driver, providing real-time data on current, temperature, and status—critical for predictive maintenance in remote power plants.