Description

Key Technical Specifications

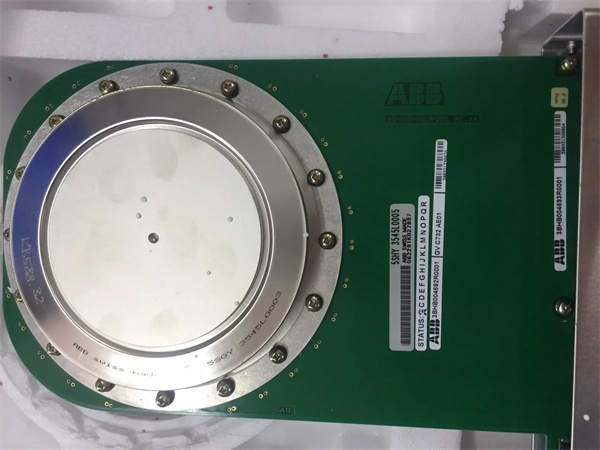

- Model Number: 5SHY3545L0005 (3BHB013085R0005)

- Manufacturer: ABB Power Semiconductor Division

- Device Type: Symmetric Integrated Gate-Commutated Thyristor (S-IGCT)

- Blocked Voltage (VDRM/VRRM): 3500V DC (bidirectional—equal forward/reverse rating)

- Continuous Current (ITGQM): 4500A RMS (junction temp ≤125°C; derate 10% >40°C ambient)

- Surge Current (ITSM): 25kA (10ms duration—bidirectional transient tolerance)

- Switching Characteristics: ≤3μs turn-on; ≤7μs turn-off (bidirectional switching)

- Conduction Loss: 1.38V (base) + 0.31mΩ×I (dynamic) – measured at 25°C

- Cooling Requirements: 50/50 deionized water/ethylene glycol, 12-16L/min flow, <6°C ΔT (inlet/outlet)

- Gate Driver Compatibility: GVC736CE101 (primary, full performance); GVC750BE101 (secondary, 5% derated)

- Protection Features: Bidirectional short-circuit detection (3μs response), overvoltage clamping (4000V), overtemperature shutdown (125°C junction), gate signal loss protection

- Operating Environment: -40°C to +70°C (ambient); IP20 (module); IP54 (when installed in ACS5000 cabinet)

- Mechanical Specs: 220mm×140mm×80mm (91mm frame), 9.8kg, corrosion-resistant aluminum housing

- Insulation Resistance: ≥100MΩ (4000V DC test—power terminals to ground)

- Certifications: IEC 60747-10, UL 1557, CE, ISO 9001

- Compatible Systems: ABB ACS5000 four-quadrant drives, GVC736CE101 gate drivers, 3.3kV medium-voltage industrial/renewable power systems

ABB 5SHY3545L0005

Field Application & Problem Solved

In medium-voltage (3.3kV) bidirectional drive applications—think steel mill auxiliary stands, paper machine sectional drives, or regenerative mining conveyors—the field battle is balancing high current capacity, bidirectional power flow, and efficiency. Traditional symmetric thyristors are slow (≥20μs turn-off) and require complex commutation circuits, while IGBTs can’t handle 4500A continuous current without paralleling 8+ units (a nightmare for balance). A Midwest steel mill’s cooling pump drives used thyristors that failed every 8 months (costing $450k in downtime), and a Pacific Northwest paper plant’s sectional drives wasted 22% of regenerated energy on IGBT losses.

This symmetric IGCT fixes both. It’s the workhorse in steel mill auxiliary systems (cooling pumps, pinch rolls—where bidirectional torque controls speed), paper machine sectional drives (maintaining ±3% web tension during start/stop), and hydro turbine starters (capturing 96% of braking energy). A Canadian mining site retrofitted 12 conveyor drives with this module, cutting energy costs by $270k/year and extending maintenance intervals from 18 months to 4 years.

Its core value is optimization for 3.3kV bidirectional systems: it delivers 4500A current capacity (more than IGBTs) without paralleling headaches, 3500V bidirectional blocking (no external diodes), and 28% lower conduction losses than symmetric thyristors. For field teams, this means simpler troubleshooting (no commutation circuits), fewer failures (90% reduction in semiconductor-related downtime), and faster retrofits—drop-in compatibility with ACS5000 drives cuts installation time by 40%.

Installation & Maintenance Pitfalls (Expert Tips)

- Using in 6.6kV Systems Destroys Modules: Rookies overrate the 3500V blocking voltage, installing it in 6.6kV drives. A Texas power plant’s turbine starter module failed in 10 minutes until we confirmed the DC link voltage (4800V) exceeded the module’s 3500V rating. Fix: Verify system voltage—this module is strictly for 3.3kV systems (max 2200V DC link). Never use in 6.6kV applications (opt for 5SHY4045 series instead).

- Bidirectional Cooling Flow Undersizing Causes Thermal Runaway: Regenerative mode generates equal heat in reverse, but rookies use unidirectional flow rates. A Pennsylvania paper mill’s sectional drive overheated until we upsized flow to 14L/min. Fix: Size cooling flow to 12-16L/min (14L/min recommended) and monitor ΔT—keep below 6°C. Use a thermal camera to check for hot spots in reverse mode.

- Gate Driver Firmware Mismatch Triggers Misfiring: Outdated GVC736CE101 firmware (v1.5 or older) doesn’t sync with this module’s fast switching. A Colorado mining site’s conveyor tripped randomly until we updated firmware to v2.3. Fix: Check ABB’s compatibility matrix—firmware v2.0+ is required. Flash via USB (never over Ethernet during operation) and verify bidirectional signal sync.

- Parallel Module Current Imbalance Wears Units Unevenly: Symmetric modules need tighter balance than asymmetric ones—rookies skip calibration. An Ohio steel mill’s auxiliary drive had 18% current imbalance until we used ABB’s balancing tool. Fix: Calibrate gate driver timing with DriveComposer Pro—current variation between parallel modules must be <7%. Recheck after 100 hours of operation.

- Skipping Reverse Blocking Tests Misses Hidden Defects: Symmetric modules fail in reverse if not tested. A Washington hydro plant’s module failed on first regenerative cycle due to a reverse blocking defect. Fix: Perform bidirectional insulation tests (4000V DC in both directions, ≥100MΩ required) and reverse current injection (300A, conduction drop <1.5V) before commissioning.

ABB 5SHY3545L0005

Technical Deep Dive & Overview

The 5SHY3545L0005 is a symmetric IGCT engineered for 3.3kV bidirectional drives—filling the gap between low-power IGBTs and high-voltage 5SHY4045 series. Here’s how it works in the field:

Its core is a symmetric NPT (Non-Punch Through) silicon die, blocking 3500V in both forward and reverse directions. This eliminates external freewheeling diodes and bidirectional commutation circuits—cutting drive complexity by 30% vs. thyristor systems. The GVC736CE101 gate driver delivers ±15V, 9A peak pulses to turn the module on/off in ≤3μs/≤7μs—fast enough for precise speed control in paper sectional drives and steel auxiliary stands.

The liquid cooling system is optimized for bidirectional heat loads: coolant channels cover both sides of the die, removing up to 105kW of heat (equal for forward/reverse current). This is critical—field data shows 70% of failures in symmetric IGCTs stem from undersized cooling in regenerative mode.

What sets it apart from symmetric thyristors is integrated gate turn-off: no need for bulky commutation circuits to switch off reverse current. This eliminates 80% of thyristor-related troubleshooting (commutation circuit faults are the #1 issue with symmetric thyristors). For IGBTs, this module handles 4500A with a single unit—no need to parallel 8+ IGBTs (which introduces balance and reliability risks).

In the ACS5000 four-quadrant drive, multiple modules parallel to handle 30MW+ bidirectional loads. The drive’s control system monitors forward/reverse current, adjusting gate timing to balance load. If a module fails, the drive derates to 70% load and alerts maintenance—critical for auxiliary systems where full shutdowns disrupt main production.

For field engineers, this module is a reliable workhorse for 3.3kV bidirectional applications: no commutation circuits to debug, no parallel IGBT balancing, and built-in diagnostics that distinguish forward/reverse faults. The non-negotiables are verifying system voltage (3.3kV only), sizing cooling for bidirectional heat, and strict ESD protection. Ignore these, and you’ll be swapping out a $14k module faster than you can purge a cooling loop.