Description

Key Technical Specifications

-

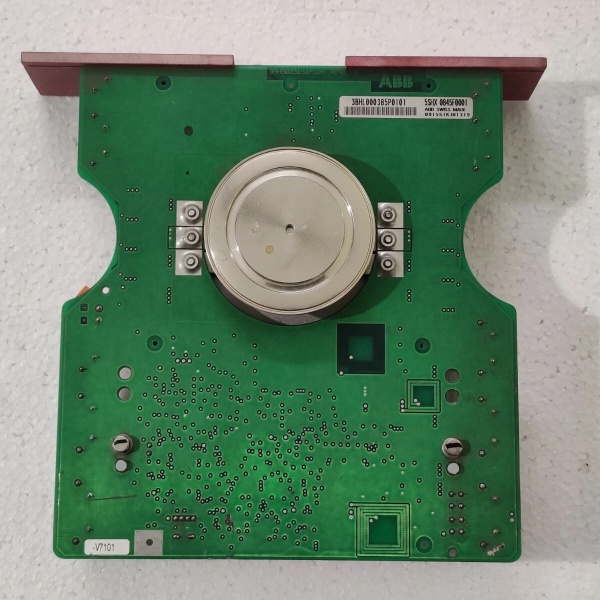

Model Number: 5SHX0845F0001

-

Manufacturer: ABB Power Electronics

-

Collector-Emitter Voltage: Vces = 1700V; Vce(sat) ≤ 1.8V @ 800A

-

Current Ratings: Ic = 800A (continuous); Icm = 2400A (peak)

-

Module Topology: Half-bridge; 2 IGBT chips + 2 freewheeling diodes (FWD)

-

Switching Characteristics: ton = 150ns; toff = 200ns; Eon = 250mJ; Eoff = 350mJ

-

Thermal Ratings: Tj = -40°C to +150°C (junction); Rth(j-c) = 0.08°C/W

-

Gate Drive Requirements: Vge = +15V/-10V (±0.5V tolerance)

-

Isolation: 4kV RMS (chip to base plate); 2kV RMS (gate to emitter)

-

Physical Dimensions: 190mm × 140mm × 30mm (L×W×H); press-fit terminals

-

Protection Features: Built-in thermistor; 10μs short-circuit withstand

-

Certifications: IEC 60747-12, UL 1557, CE

ABB 5SHX0845F0001

Field Application & Problem Solved

In power plants, refineries, and steel mills, the cost of an IGBT module failure isn’t just the part—it’s the downtime. I’ve seen a single bad module take down a 200kW ball mill drive at a mining site, costing $45,000 an hour in lost production. Legacy or off-brand modules fail here because they can’t handle two things: the constant thermal cycling from load swings and the short-circuit spikes from motor stalls. At a Texas refinery, we replaced three generic modules in six months before switching to this ABB unit—zero failures in two years since.

You’ll find this module at the heart of ABB ACS800 medium-voltage drives—powering everything from centrifugal compressors to conveyor systems. It’s the “muscle” that converts DC bus voltage to variable-frequency AC for the motor. Its core value is balance: 1700V handles the high-voltage bus in 10kV drives, 800A delivers the current for heavy loads, and the optimized chip design cuts switching losses by 25% compared to older models. A paper mill in Wisconsin swapped out aging modules for these and saw a 3% drop in drive power consumption—enough to pay for the upgrade in 11 months.

Its 10μs short-circuit withstand is what makes it reliable in harsh spots. Last year, a chemical plant in Louisiana had a motor seize—this module held up long enough for the drive’s protection system to trip, avoiding a catastrophic explosion of the IGBT. The press-fit terminals are another win for us in the field: no soldering, just push to seat. We swapped a failed unit in 45 minutes during a scheduled break, instead of the 4 hours a soldered module would have taken.

Installation & Maintenance Pitfalls (Expert Tips)

Gate Drive Voltage Tolerance Is Non-Negotiable

Rookies think any 15V supply works—wrong. This module dies fast if gate voltage drifts beyond +15.5V or below -9.5V. A cement plant in Ohio used a generic drive board that spiked to +17V; the module’s Vce(sat) doubled in a month, leading to overheating. Always use ABB’s OEM drive board and calibrate with a multimeter before power-up. Match the drive resistor to the manual (10Ω/2W is standard)—too small fries the gate, too large causes slow switching and excess heat.

Thermal Grease Thickness = Life or Death

I’ve seen more modules fail from bad thermal mounting than anything else. The radiator surface must be flat (≤0.1mm) and clean—no paint, no scratches. Apply a thin bead of thermal grease (0.1-0.2mm thick, not a blob) and torque the mounting bolts to 8N·m. A power plant in Florida ignored this; dust built up between the module and radiator, pushing Tj to 175°C and tripping the drive. We cleaned the surface, reapplied grease, and Tj dropped to 82°C. For parallel modules, ensure current balance—more than 10% mismatch burns out the overloaded unit.

Static Kills—Wear the Bracelet

The gate oxide layer is thinner than a human hair—static from your hand will punch a hole in it. I had a tech at a Pennsylvania plant skip the grounding bracelet; he touched the gate terminal, and the module shorted on power-up. Always store the module in its防静电 (ESD) bag until installation, and clip the bracelet to the drive’s chassis (not just any ground). Never stack modules—pressure on the terminals bends the substrate, leading to internal cracks that fail weeks later.

Drive Protection Settings Must Match the Module

Don’t reuse old drive parameters. Set overcurrent protection to 1200A (1.5x rated), overtemp to 140°C, and short-circuit response to 8μs—fast enough to protect the module but slow enough to avoid false trips. A paper mill kept the old 800A overcurrent setting; every motor start tripped the drive. We adjusted the parameters, and it ran flawlessly. Use an oscilloscope to check switching waveforms during commissioning—ringing or voltage spikes mean you need to add snubber capacitors.

ABB 5SHX0845F0001

Technical Deep Dive & Overview

This module is a half-bridge IGBT designed for high-power conversion, built with ABB’s NPT (Non-Punch Through) chips and field-stop technology—this combo lets it handle high voltage without sacrificing switching speed. The integrated freewheeling diodes are fast-recovery (trr = 50ns), which cuts down on voltage spikes when the motor regenerates power back to the drive. The ceramic substrate and copper base plate aren’t just for show—they pull heat away from the chips 30% better than aluminum-based designs, critical for 24/7 operation.

Inside the ACS800 drive, multiple modules are paralleled to handle higher currents—ABB’s design ensures each module carries equal load, so one doesn’t get stuck doing all the work. The press-fit terminals use spring-loaded contacts that maintain a tight connection even with vibration, which is why these hold up in steel mills and mining sites. The built-in thermistor feeds real-time temperature data to the drive, triggering warnings before overheating becomes a failure.

With a MTBF (Mean Time Between Failures) of over 100,000 hours, it’s built for the harsh environments we work in—from -40°C in Alaska’s oil fields to +85°C in Arizona’s power plants. The 4kV isolation rating keeps it safe in medium-voltage cabinets, and the rugged packaging survives the bumps and jolts of plant floors. This isn’t a “fancy” component—it’s a workhorse that does exactly what it needs to, as long as you install and maintain it right.