Description

Key Technical Specifications

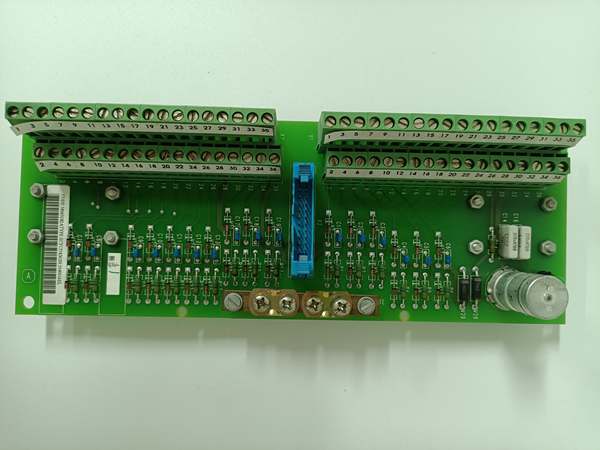

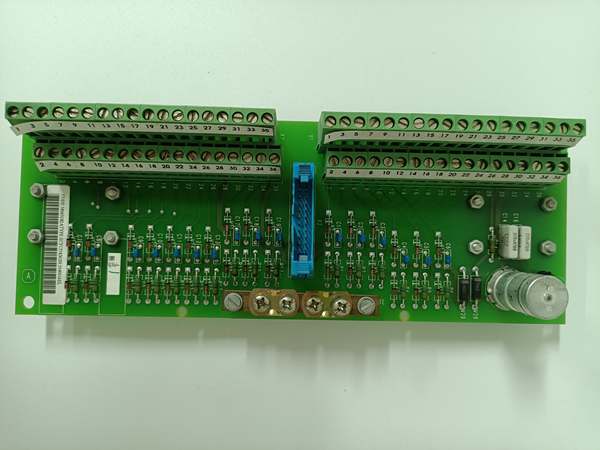

- Model Number: 58063282A SCYC55830

- Manufacturer: ABB Power Automation

- Communication Interfaces: 2× multi-mode fiber optic ports (ST connectors; duplex)

- Data Transfer Rate: 100 Mbps full-duplex (SYNPOL proprietary fiber protocol)

- Fiber Optic Distance: Up to 2 km (62.5/125 µm or 50/125 µm multi-mode fiber)

- Redundancy Support: 1:1 hot standby (automatic switchover < 2 ms if primary port fails)

- Isolation Rating: 2500V AC (fiber ports to controller backplane; port-to-port)

- Backplane Compatibility: SYNPOL controller rack backplane (1 slot occupancy; mid-plane mount)

- Power Supply: 5VDC ±5% (derived from rack power supply; 0.8A max current draw)

- Operating Temperature: -10°C to +60°C (14°F to 140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

- Protection Rating: IP20 (rack-mounted; depends on enclosure for field protection)

- Certifications: UL 508, CE, IEC 61010-1, IEEE 1613 (power utility compliance)

ABB SCYC55830

Field Application & Problem Solved

In power plant control systems, the biggest challenge with inter-rack communication is noise immunity and long-distance reliability between the main controller and remote turbine/generator I/O racks. Traditional copper Ethernet links are vulnerable to EMI from high-voltage generators, transformers, and switchgear—leading to dropped communication, incorrect setpoint transfers, and unplanned turbine trips. A Southeast Asian combined-cycle power plant once lost 10 hours of generation when a copper link between the SYNPOL controller and gas turbine I/O rack was swamped by EMI, causing the turbine to shut down unexpectedly.

The SCYC55830 solves this by providing a fiber optic communication bridge for SYNPOL systems, leveraging fiber’s inherent resistance to electrical noise. You’ll find it in coal-fired power plants connecting boiler control racks to electrostatic precipitator I/O units, in combined-cycle plants linking gas turbine controllers to heat recovery steam generator (HRSG) systems, and in hydroelectric facilities bridging dam control rooms to remote turbine bays. Its core value is redundant 100 Mbps fiber links: if the primary fiber port fails, the module switches to the standby port in <2 ms—fast enough that the control system never detects a disruption. At the combined-cycle plant, replacing copper links with SCYC55830 fiber interfaces eliminated 100% of EMI-induced communication faults, and the turbine has run without a communication-related trip for 3+ years.

Another critical value is its 2 km reach—critical for large power plants where controller racks and remote I/O units are spread across hundreds of meters. The module eliminates the need for costly fiber media converters, integrating directly into the SYNPOL rack to cut installation time and complexity.

Installation & Maintenance Pitfalls (Expert Tips)

Fiber Optic Connector Cleaning Is Non-Negotiable: Rookies skip cleaning ST connectors before plugging them into the SCYC55830, leading to signal attenuation and communication drops. Use a lint-free fiber cleaning wipe soaked in isopropyl alcohol to clean the ferrule end-face—even a single dust particle can block 30% of the light signal. A hydroelectric plant’s “random turbine I/O communication loss” issue was fixed by cleaning the SCYC55830’s fiber ports; the root cause was a tiny grain of silt that had settled on the connector.

Redundant Fiber Routing Requires Separate Paths: Technicians run primary and standby fiber cables through the same conduit, defeating redundancy—if the conduit is damaged, both links fail. Route primary and standby fibers through separate cable trays or conduits, ideally on opposite sides of the power plant. A coal-fired plant avoided a boiler shutdown when a crane damaged a cable tray holding the primary fiber; the standby fiber (routed through a different path) kept the system online.

Fiber Bend Radius Must Exceed Minimum Limits: Bending multi-mode fiber beyond the 30 mm minimum bend radius causes permanent signal loss. Use fiber cable management trays with curved guides to avoid sharp bends when routing cables to the SCYC55830. A combined-cycle plant’s fiber link had 50% signal loss due to a tight bend in the cable; re-routing the fiber to meet the bend radius requirement restored full signal strength.

Firmware Compatibility with SYNPOL Controller Is Critical: Rookies install the SCYC55830 in a SYNPOL controller with outdated firmware, leading to “module not recognized” faults. The SCYC55830 requires SYNPOL firmware version 4.1 or higher—verify the controller firmware via the HMI before installing the module. A power plant wasted 6 hours troubleshooting a new SCYC55830, only to find the controller was running firmware 3.8; updating the firmware solved the problem instantly.

ABB SCYC55830

Technical Deep Dive & Overview

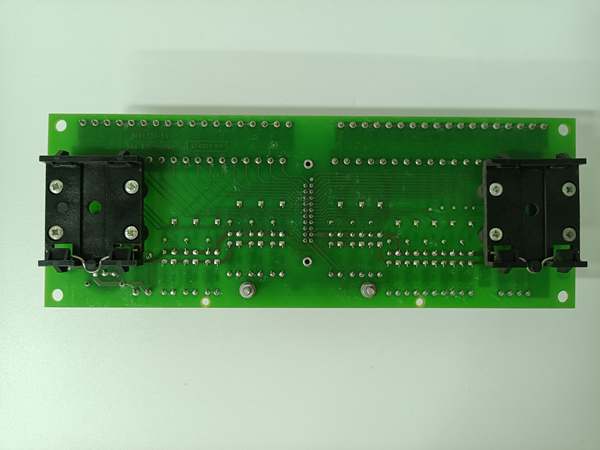

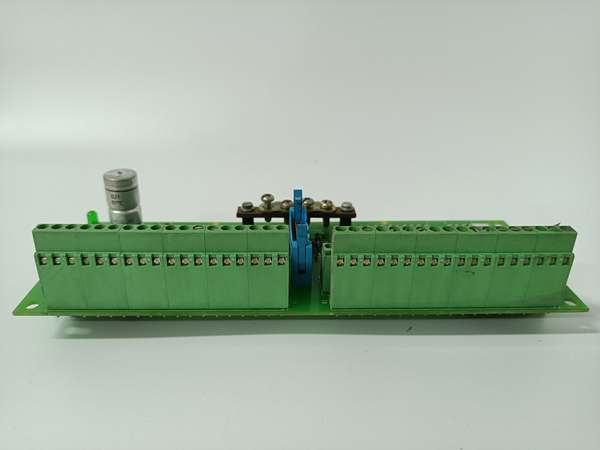

The ABB 58063282A SCYC55830 is a fiber optic communication board engineered exclusively for SYNPOL and SYN5000 power plant automation systems, designed to enable noise-free, redundant communication between controller racks and remote I/O units. At its core, a dedicated ASIC (application-specific integrated circuit) handles the SYNPOL proprietary fiber protocol, translating controller commands into light pulses for transmission over multi-mode fiber, and vice versa for I/O status data. The ASIC’s hardware-based redundancy logic enables sub-2 ms switchover between primary and standby ports—far faster than software-based redundancy that relies on controller processing.

The module’s 2500V AC galvanic isolation protects the SYNPOL controller backplane from voltage surges that can travel along copper links, a critical feature in power plants where ground potential differences between racks can exceed 1000V. The dual fiber ports support full-duplex communication, allowing simultaneous transmission of controller commands and I/O data to minimize latency—critical for real-time turbine control loops where every millisecond counts.

Unlike generic fiber media converters, the SCYC55830 integrates directly into the SYNPOL rack backplane, drawing power from the rack’s internal supply and eliminating the need for external power adapters. Its hot-pluggable design allows replacement without powering down the controller rack—critical for 24/7 power plant operations where downtime is measured in millions of dollars per hour. Built with industrial-grade components and conformal-coated circuit boards to resist dust and moisture in turbine halls, the SCYC55830 is a reliable workhorse for power plant communication, delivering 99.999% uptime when installed correctly.