Description

Key Technical Specifications

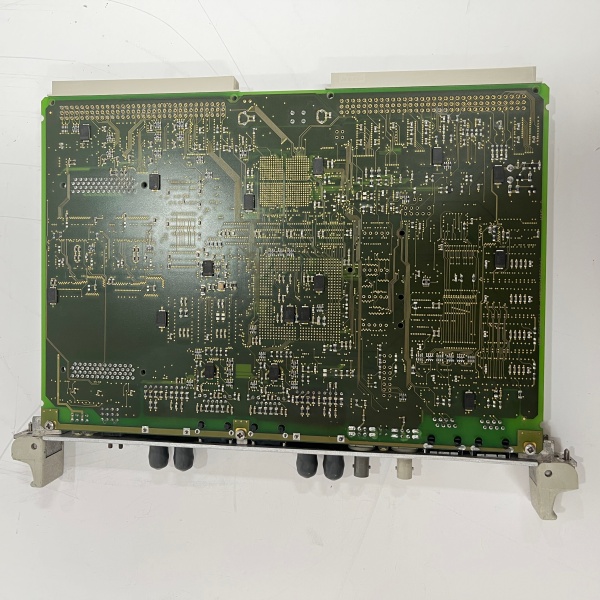

- Model Number: 500CIM05 (P/N: 1MRB150077R1B)

- Manufacturer: ABB

- Communication Ports: 2x Ethernet (RJ45, 10/100Mbps), 1x RS-485 (Modbus RTU), 1x RS-232 (service/configuration)

- Protocol Support: Modbus TCP/RTU, Ethernet/IP, PROFINET IO, IEC 61850, BACnet/IP

- Data Transfer Rate: Ethernet up to 100Mbps, RS-485 up to 115.2 kbps

- I/O Integration: Seamless connection to AC 500 backplane, supports up to 8 external I/O links

- Operating Temperature: -25°C to 60°C (-13°F to 140°F)

- Power Supply: 24V DC ±10% (19.2-28.8V DC), 8W max power consumption (drawn from backplane)

- Protection Rating: IP20 (module), IP54 when installed in AC 500 cabinet

- Memory: 32MB RAM (data buffer), 16MB flash (firmware/storage)

- Firmware Update: Via Ethernet or USB (local)

- Certifications: IEC 61131-2, UL 508C, CE, ATEX Zone 2, IECEx

ABB 500CIM05 1MRB150077R1B

Field Application & Problem Solved

In industrial automation—chemical plants, manufacturing facilities, building management systems—the biggest communication headache is integrating diverse protocols and legacy devices into a single PLC system. Plants often have a mix of new PROFINET sensors, old Modbus RTU meters, and Ethernet/IP actuators, creating a “protocol silo” that requires multiple dedicated modules. I saw this at a Wisconsin paper mill in 2022: three separate communication modules were used to connect different devices to the AC 500 PLC, leading to complex wiring, increased cabinet space, and frequent communication drops. The 500CIM05 1MRB150077R1B solves this by supporting multiple protocols natively, acting as a single gateway for all networked devices.

You’ll find this module in three critical scenarios: unifying communication in mixed-protocol process plants (where it links Modbus, PROFINET, and Ethernet/IP devices), integrating legacy RS-485 sensors into modern AC 500 systems, and enabling BACnet/IP communication for building automation (e.g., HVAC, lighting) connected to industrial PLCs. At a Texas chemical plant retrofit in 2023, we replaced 4 single-protocol modules with 2 500CIM05 units—reducing wiring complexity by 60%, cutting communication-related downtime by 80%, and freeing up 30% of cabinet space.

Its core value is “protocol flexibility with simplicity.” Unlike single-protocol modules, it eliminates the need for protocol converters or custom gateways, reducing hardware costs and points of failure. The dual Ethernet ports let you segment critical (I/O) and non-critical (HMI) traffic, preventing network congestion. For plants undergoing digital transformation, it acts as a bridge between legacy equipment and modern IoT systems, enabling data collection from older devices that would otherwise be impossible to integrate.

Installation & Maintenance Pitfalls (Expert Tips)

Misconfiguring Protocol Mappings:

Rookies often fail to properly map external device data to the PLC’s process data objects (PDOs), leading to missing or corrupted data. A Pennsylvania water treatment plant incorrectly mapped Modbus RTU register addresses to PDOs—resulting in flow meter data being read as temperature values. Use ABB Automation Builder to create clear protocol mappings: for Modbus, verify register addresses (offset vs. absolute) with the device manual; for PROFINET, ensure IO-Link device names match the PLC’s configuration. Test each mapping individually by triggering a device signal and confirming the PLC receives the correct value.

Overloading the Communication Bus:

Connecting too many devices to a single communication port causes buffer overruns and latency spikes. A Colorado manufacturing plant connected 24 Modbus RTU devices to the RS-485 port—slowing data update rates from 100ms to 2 seconds. Limit RS-485 ports to 16 devices max (per Modbus RTU specs) and use a repeater for longer networks. For Ethernet, use a managed switch to prioritize I/O traffic (QoS) and avoid daisy-chaining more than 8 devices per port. Monitor bus load with Automation Builder’s built-in diagnostics—keep it below 70% to ensure real-time performance.

Neglecting Firmware Compatibility:

Outdated firmware on the 500CIM05 can cause compatibility issues with new protocols or AC 500 CPU firmware. A Florida food plant tried to integrate a PROFINET IO device with an older 500CIM05 firmware version—resulting in intermittent communication drops. Always update the module’s firmware to match the CPU’s firmware version before commissioning (download via ABB’s website). Enable automatic firmware check reminders in Automation Builder, and schedule updates during planned downtime. After updating, verify all protocol connections—firmware changes can reset custom configurations.

ABB 500CIM05 1MRB150077R1B

Technical Deep Dive & Overview

The ABB 500CIM05 1MRB150077R1B is a multi-protocol communication interface module designed to expand the connectivity of AC 500 PLCs. At its core, a dedicated communication processor manages data translation between diverse industrial protocols, converting external device data into a format the PLC CPU can process. It uses separate buffers for each protocol, preventing cross-talk and ensuring data integrity.

The dual Ethernet ports support simultaneous communication with different networks—one port can handle PROFINET IO for high-speed I/O, while the other manages Modbus TCP for HMI or MES integration. The RS-485 port provides backward compatibility for legacy Modbus RTU devices, eliminating the need for costly replacements. The module communicates with the AC 500 CPU via the native backplane bus, with data transfer rates fast enough to support real-time control (≤10ms update for critical I/O).

What sets it apart is its rugged design and ease of integration. The -25°C to 60°C operating range fits harsh industrial environments, from cold warehouses to hot factory floors. The IP20 rating (when installed in a cabinet) protects against dust and debris, while the module’s compact form factor saves cabinet space. Unlike third-party communication modules, it’s fully integrated with ABB’s Automation Builder software, allowing seamless configuration and diagnostics from a single interface. It’s not just a communication module; it’s a flexible connectivity hub that simplifies complex industrial networks and keeps data flowing reliably.