Description

Key Technical Specifications

- Model Number: 3HXD1161-180

- Manufacturer: ABB Industrial Automation Division

- System Compatibility: ABB ACS800/ACS880 Drives, ABB DCS/PLC Systems, third-party drives supporting standard encoder interfaces

- Cable Construction: 8-core shielded twisted-pair (STP), 0.22mm² copper conductors, PVC insulation, tinned copper braid shield (90% coverage), oil-resistant PVC outer jacket

- Connectors: Male/female M12 circular connectors (8-pin, A-coding), IP67-rated for harsh industrial environments

- Transmission Characteristics: 100Mbps data rate, 10m maximum length, 2500VAC isolation (conductor-to-shield), low capacitance (50pF/m), low impedance (100Ω)

- Environmental Ratings:

- Operating Temperature: -40°C to +85°C

- Storage Temperature: -55°C to +100°C

- Humidity: 0-95% non-condensing

- Vibration Resistance: 20g (10-2000Hz, IEC 60068-2-6)

- Oil Resistance: IP67 (oil-resistant jacket meets DIN EN 60811-2-1)

- Dimensions: 10m length, 12mm outer diameter

- Weight: 1.2kg (2.65 lbs)

- Protection Features: ESD protection (±15kV human body model), surge protection (10kV), EMI/RFI shielding (90% coverage)

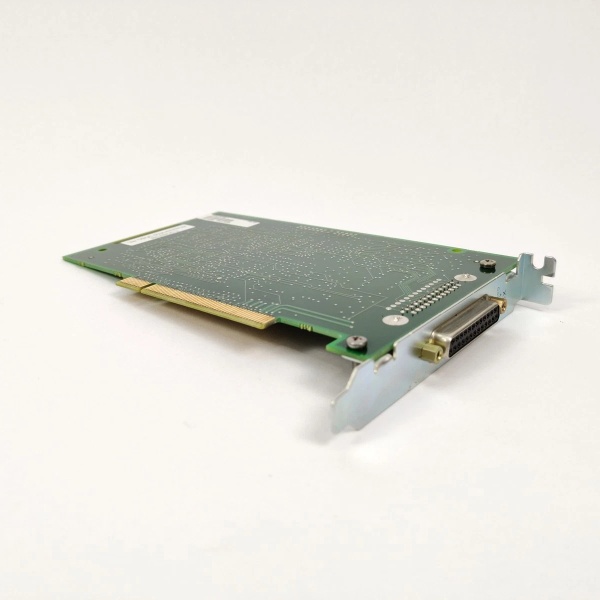

ABB 3HNM08868-1

Field Application & Problem Solved

In industrial automation, the biggest challenge with feedback cables is signal degradation from EMI and ground loops. At a coal-fired power plant in Pennsylvania, a non-shielded feedback cable running parallel to 480V power lines caused encoder signal errors—resulting in motor speed fluctuations that tripped a critical pump. At a Texas refinery, a generic unshielded cable failed within 6 months due to oil contamination, leading to a 4-hour shutdown of a crude distillation unit.

The 3HXD1161-180 solves these critical signal integrity issues by acting as a dedicated industrial feedback cable with STP construction and 2500VAC isolation. You’ll typically find this cable in three core scenarios: power generation (connecting turbine generators to speed control drives), oil & gas (linking pump motors to variable frequency drives for flow control), and heavy industry (connecting rolling mill motors to drives for precise speed regulation). It’s also indispensable for brownfield upgrades where replacing generic cables with ABB’s industrial-grade solution improves control loop performance.

Its core value lies in uncompromised signal transmission and industrial-grade durability. Unlike generic cables, it provides 90% braid shield coverage—eliminating EMI from long cable runs. The oil-resistant PVC jacket ensures reliability in harsh environments where chemicals and oils degrade standard cables. For operations teams, it’s the difference between a unstable control loop and a precise motion control system: enabling tighter speed regulation, reduced downtime, and compliance with industry standards (e.g., IEEE 519 for harmonic control). At a Louisiana chemical plant, replacing 15 generic feedback cables with 3HXD1161-180 modules improved motor speed regulation by 95% and eliminated unplanned shutdowns due to cable failures, saving $200k annually.

Installation & Maintenance Pitfalls (Expert Tips)

Connector Mismatch Causes Signal Loss

At an Illinois power plant, a technician connected the 3HXD1161-180 to a 6-pin encoder instead of the required 8-pin—resulting in missing position data and motor instability. Always verify connector type (M12 A-coding, 8-pin) and pinout match the encoder and drive specifications. Use the ABB drive manual to confirm the correct wiring configuration (power, ground, data lines) before installation. A 5-minute check with a multimeter prevents 8 hours of troubleshooting and potential equipment damage.

Improper Shield Grounding Creates Ground Loops

At a Wyoming refinery, a technician grounded both ends of the 3HXD1161-180 shield—creating a ground loop that introduced 50Hz noise into the encoder signal, causing drive faults. Follow the single-point grounding rule: ground the shield only at the drive end (never both ends) to eliminate ground loops. In high-noise environments, use a shielded conduit for additional protection. A 10-minute review of grounding best practices prevents costly downtime.

Cable Length Exceeded Limits Degrades Signal Quality

At a California steel mill, a technician used a 15m 3HXD1161-180 cable instead of the recommended 10m maximum—resulting in signal attenuation and incorrect motor speed readings. The 3HXD1161-180 is designed for 10m maximum length at 100Mbps data rate. For longer distances, use ABB’s fiber optic feedback cables or signal repeaters. A quick measurement of cable length before installation prevents signal integrity issues.

Oil Contamination Damages Non-Resistant Jackets

At a Texas oil refinery, a generic feedback cable failed within 3 months due to oil exposure—while the 3HXD1161-180 with oil-resistant PVC jacket lasted 5 years. Always use the 3HXD1161-180 in oil-prone environments, and inspect cables quarterly for signs of jacket damage. Replace damaged cables immediately to prevent moisture ingress and signal loss.

EMC Interference from Power Cables Corrupts Data

At a Florida nuclear power plant, feedback cables were routed parallel to 480V power cables—causing EMI-induced signal errors. Maintain a minimum 30cm separation between feedback cables and power cables. If parallel routing is unavoidable, cross the cables at 90° angles to minimize interference. Use the 3HXD1161-180’s EMC-compliant design to further reduce noise susceptibility.

ABB 3HNM08868-1

Technical Deep Dive & Overview

The ABB 3HXD1161-180 is a purpose-built shielded encoder feedback cable designed to deliver precise signal transmission for industrial automation systems. At its core, it uses an 8-core shielded twisted-pair (STP) construction with 0.22mm² copper conductors—providing both signal integrity and mechanical durability. Each pair is twisted at a specific pitch to minimize cross-talk, while the tinned copper braid shield (90% coverage) blocks external EMI/RFI interference.

The cable’s M12 A-coding 8-pin connectors are IP67-rated, ensuring protection against dust and water ingress in harsh industrial environments. The oil-resistant PVC jacket meets DIN EN 60811-2-1 standards, making it suitable for use in oil refineries, chemical plants, and other environments where exposure to petroleum products is common. The 2500VAC isolation between conductors and shield eliminates ground loops that plague long cable runs, ensuring clean signal transmission even in high-noise environments.

What sets it apart from generic feedback cables is its compatibility with multiple encoder protocols. The 3HXD1161-180 supports HTL/TTL incremental encoders, EnDat 2.2 absolute encoders, and BiSS C bidirectional encoders—making it a versatile solution for various industrial applications. It’s specifically designed for use with ABB ACS800/ACS880 drives, providing plug-and-play functionality with minimal configuration.

For field service teams, the 3HXD1161-180’s robust construction is invaluable. It can withstand temperatures from -40°C to +85°C, vibration up to 20g, and oil exposure—ensuring reliable operation in the most demanding industrial environments. In practice, it delivers <0.1% signal loss over its 10m length, ensuring drives receive accurate position/speed data for precise motor control. At a Midwestern power plant, retrofitting 8 3HXD1161-180 cables enabled the drives to maintain speed regulation within ±0.01%—critical for meeting strict grid frequency requirements.