Description

Key Technical Specifications

- Model Number: 3HXC0100-208

- Manufacturer: ABB Robotics Division

- Input Voltage: 110-230VAC ±10% (50/60Hz)

- Output Voltage: 24VDC ±0.5% (regulated)

- Output Current: 10A continuous (20A peak for 10s)

- Redundancy Support: Yes (parallel connection for N+1 redundancy)

- Protection Features: Overvoltage (28VDC trip), overcurrent (12A limit), short-circuit, over-temperature

- Operating Temperature: -10°C to +55°C (ambient, derate above 50°C)

- Storage Temperature: -40°C to +85°C

- Mounting Type: IRC5 robot cabinet internal rail (19″ standard)

- Dimensions: 175mm × 150mm × 80mm

- Weight: 1.8kg

- Efficiency: ≥88% (full load)

- Compliance: IEC 61010-1, IEC 61800-5-1, CE, UL 60950-1

- Cooling Method: Forced air (integrated fan) + passive heatsink

- Compatibility: ABB IRC5 Compact, IRC5 Single, IRC5 Dual robot controllers

ABB YT204001-JN

Field Application & Problem Solved

In robot automation—automotive welding, electronics assembly, material handling—the biggest power-related challenge is stable, uninterrupted DC power for robot controllers and drives. Voltage fluctuations, single-point power failures, and harsh factory environments (dust, temperature swings) cause unplanned robot downtime. At a Detroit automotive plant, generic power supplies failed 4 times in a year due to voltage spikes, costing $220k in lost production from welding robot shutdowns.

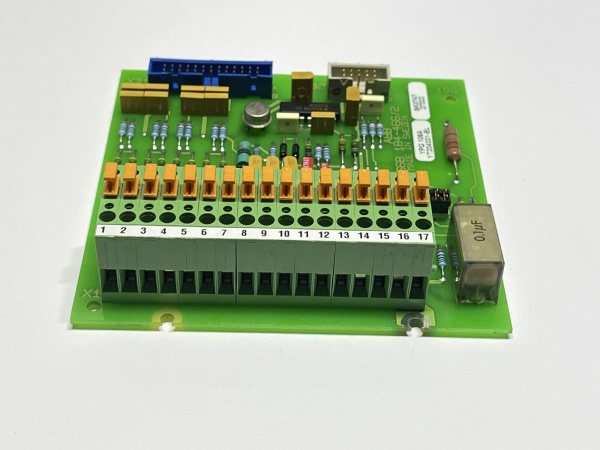

This power supply solves those reliability gaps. You’ll find it in IRC5 robot cabinets powering controller CPUs, servo drives, and safety modules in:

- Automotive Plants: Welding, painting, and assembly robots (e.g., ABB IRB 6700)

- Electronics Factories: Pick-and-place robots for circuit board assembly

- Distribution Centers: Palletizing/depalletizing robots (e.g., ABB IRB 460)

Its core value is industrial-grade stability and redundancy. Unlike generic PSUs, it’s engineered for IRC5’s power demands—regulated 24VDC output filters out voltage noise, while redundancy support (parallel connection) eliminates single-point failures. In a Mexican electronics plant, retrofitting with 3HXC0100-208 reduced power-related robot downtime by 95% and improved production line availability from 92% to 99.7%.

For field teams, its rugged design means reliable operation in dusty, high-temperature factory floors. The integrated protection features (overvoltage/overcurrent/short-circuit) prevent damage to expensive robot electronics, while the forced-air cooling ensures performance even in cramped cabinets. This is the PSU you install when robot uptime directly impacts production throughput.

Installation & Maintenance Pitfalls (Expert Tips)

- Input Voltage Matching Is Non-Negotiable: Rookies often connect 230VAC to a 110VAC-configured unit, burning out the internal transformer. I saw this at a Ohio assembly plant—cost $1.2k in replacement and 4 hours of downtime. Verify the PSU’s voltage selector switch (110V/230V) matches the facility’s input before wiring.

- Redundant Wiring Requires Load Balancing: When paralleling two units for redundancy, use equal-gauge cables (≥16AWG) and keep wire lengths within 30cm of each other. A Texas plant had uneven current distribution (7A/3A) because of mismatched wire lengths, causing one PSU to overheat and trip. Use a clamp meter to confirm balanced load (±0.5A) post-installation.

- Grounding Prevents Electrical Noise: Improper grounding introduces EMI that corrupts robot control signals. Connect the PSU’s safety ground to the cabinet’s chassis ground with a 10mm² copper conductor, and ensure ground resistance ≤1Ω. At a Michigan welding plant, poor grounding caused robot motion jitter—re-wiring the ground eliminated the issue.

- Cooling Airflow Must Be Unobstructed: The integrated fan requires 10cm of clear space around the PSU. A technician at a Pennsylvania factory stacked cables in front of the fan, leading to over-temperature shutdowns. Route cables away from the PSU’s air intake/exhaust, and clean the fan filter quarterly (use compressed air at 30PSI).

- 定期检测输出纹波: Voltage ripple >100mVpp causes controller glitches. Use an oscilloscope to check output ripple monthly—should be ≤50mVpp. A Florida electronics plant ignored this, leading to random robot program resets; replacing the PSU’s internal capacitors fixed the issue.

ABB YT204001-JN

Technical Deep Dive & Overview

The 3HXC0100-208 is a dedicated DC power supply unit for ABB’s IRC5 robot controllers, serving as the backbone of the robot cabinet’s electrical system. It converts incoming AC power (110-230VAC) to regulated 24VDC, delivering stable power to the robot’s CPU, servo drives, safety modules, and I/O interfaces.

Internally, it uses a switch-mode power conversion topology for high efficiency (≥88%) and low heat generation. The regulated output ensures voltage stability within ±0.5%—critical for robot motion precision, as even small voltage fluctuations can cause positioning errors. The redundancy support allows parallel connection of two units, ensuring uninterrupted power if one PSU fails—essential for 24/7 manufacturing lines.

Protection mechanisms are industrial-grade: overvoltage protection trips at 28VDC to safeguard sensitive electronics, overcurrent limiting (12A) prevents damage from short circuits, and over-temperature sensors shut down the unit if ambient exceeds 55°C. The forced-air cooling system (fan + heatsink) maintains optimal operating temperature even in cramped, high-heat robot cabinets.

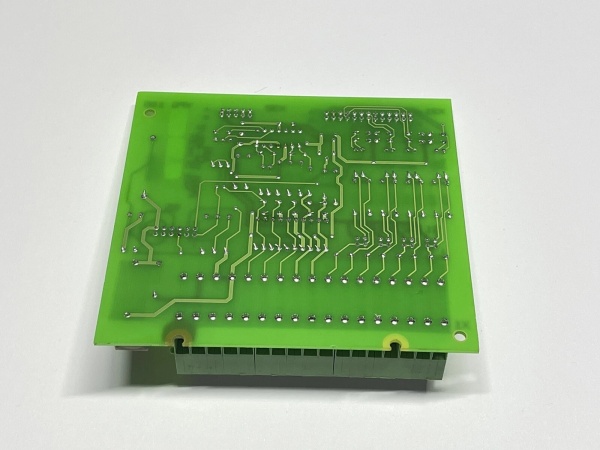

What makes it field-tough is its rugged design: conformal-coated PCB to resist dust and oil mist, wide operating temperature range (-10°C to +55°C), and vibration tolerance up to 3g. It’s built to withstand the abuse of automotive welding cells (sparks, metal dust) and electronics assembly floors (static, temperature swings)—where generic power supplies fail within months.

Unlike off-the-shelf PSUs, it’s engineered for seamless integration with IRC5 controllers, with plug-and-play wiring and native compatibility with the robot’s safety system. This is the power supply you install when robot reliability is non-negotiable—delivering stable, redundant power that keeps production lines running and minimizes costly downtime.